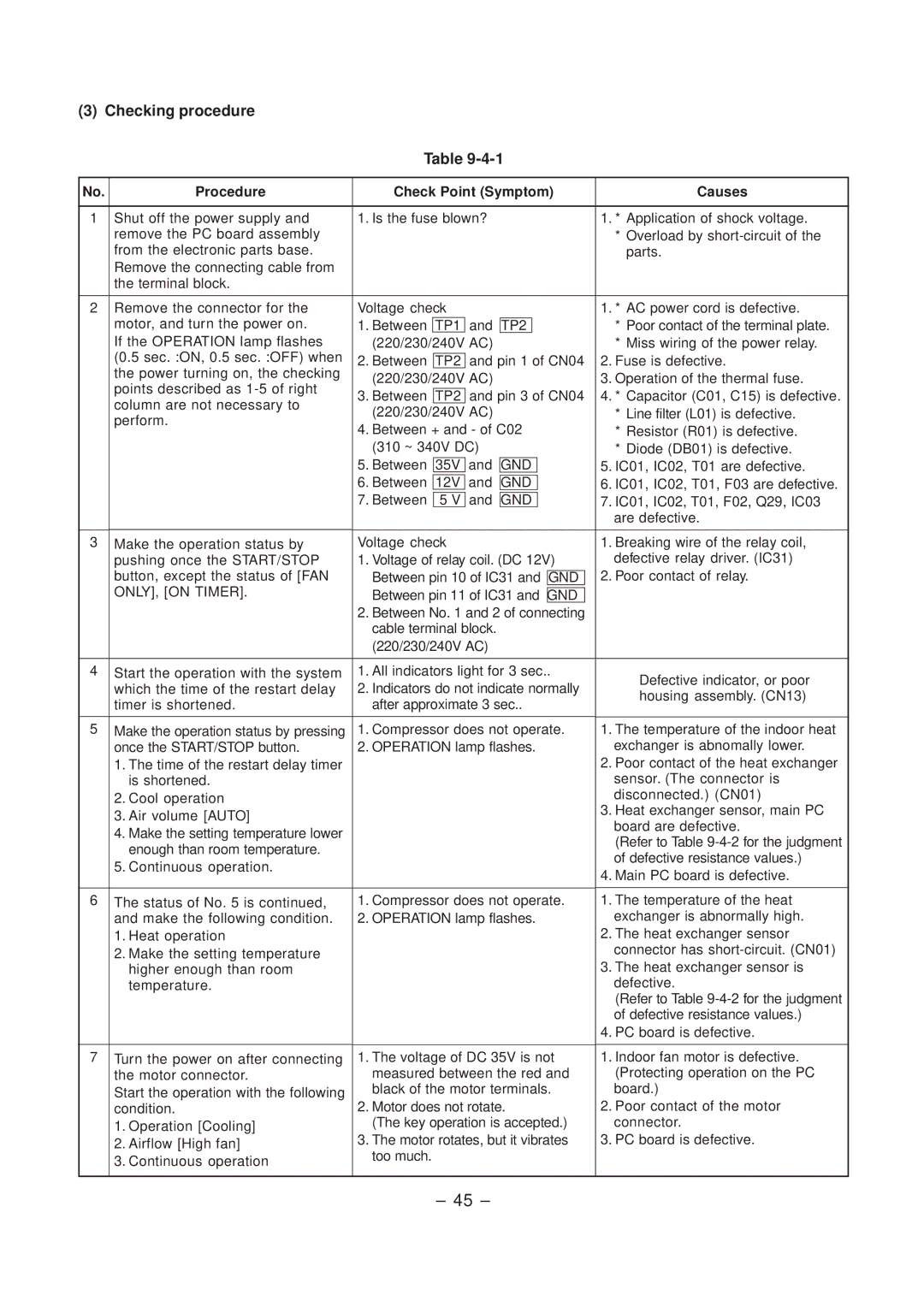

(3) Checking procedure

Table

No. | Procedure | Check Point (Symptom) |

| Causes | |||||||

|

|

|

|

|

|

|

|

|

|

| |

1 | Shut off the power supply and | 1. Is the fuse blown? |

|

|

|

|

| 1. * Application of shock voltage. | |||

| remove the PC board assembly |

|

|

|

|

|

|

|

| * Overload by | |

| from the electronic parts base. |

|

|

|

|

|

|

|

|

| parts. |

| Remove the connecting cable from |

|

|

|

|

|

|

|

|

|

|

| the terminal block. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

2 | Remove the connector for the | Voltage check |

|

|

|

|

|

| 1. * AC power cord is defective. | ||

| motor, and turn the power on. | 1. Between |

| and |

|

|

|

|

| * Poor contact of the terminal plate. | |

| TP1 | TP2 |

|

|

|

| |||||

| If the OPERATION lamp flashes | (220/230/240V AC) |

|

|

|

|

| * Miss wiring of the power relay. | |||

| (0.5 sec. :ON, 0.5 sec. :OFF) when | 2. Between |

| and pin 1 of CN04 | 2. Fuse is defective. | ||||||

| TP2 | ||||||||||

| the power turning on, the checking | (220/230/240V AC) |

|

|

|

|

| 3. Operation of the thermal fuse. | |||

| points described as |

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

| |

| 3. Between | TP2 | and pin 3 of CN04 | 4. * Capacitor (C01, C15) is defective. | |||||||

| column are not necessary to | ||||||||||

| (220/230/240V AC) |

|

|

|

|

| * Line filter (L01) is defective. | ||||

| perform. |

|

|

|

|

| |||||

| 4. Between + and - of C02 | * Resistor (R01) is defective. | |||||||||

|

| ||||||||||

|

| (310 ~ 340V DC) |

|

|

|

|

| * Diode (DB01) is defective. | |||

|

| 5. Between | 35V | and | GND |

|

|

| 5. IC01, IC02, T01 are defective. | ||

|

| 6. Between | 12V | and | GND |

|

|

| 6. IC01, IC02, T01, F03 are defective. | ||

|

| 7. Between | 5 V | and | GND |

|

|

| 7. IC01, IC02, T01, F02, Q29, IC03 | ||

|

|

|

|

|

|

|

|

|

| are defective. | |

|

|

|

|

|

|

|

|

|

|

| |

3 | Make the operation status by | Voltage check |

|

|

|

|

|

| 1. Breaking wire of the relay coil, | ||

| pushing once the START/STOP | 1. Voltage of relay coil. (DC 12V) | defective relay driver. (IC31) | ||||||||

| button, except the status of [FAN | Between pin 10 of IC31 and |

|

| 2. Poor contact of relay. | ||||||

| GND | ||||||||||

| ONLY], [ON TIMER]. | Between pin 11 of IC31 and |

|

|

|

| |||||

| GND |

|

| ||||||||

|

| 2. Between No. 1 and 2 of connecting |

|

| |||||||

|

| cable terminal block. |

|

|

|

|

|

|

| ||

|

| (220/230/240V AC) |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

4 | Start the operation with the system | 1. All indicators light for 3 sec.. | ü | Defective indicator, or poor | |||||||

|

|

|

|

|

|

|

|

| |||

| which the time of the restart delay | 2. Indicators do not indicate normally | ý | housing assembly. (CN13) | |||||||

| timer is shortened. | after approximate 3 sec.. | þ |

| |||||||

5 | Make the operation status by pressing | 1. Compressor does not operate. | 1. The temperature of the indoor heat | ||||||||

| once the START/STOP button. | 2. OPERATION lamp flashes. | exchanger is abnomally lower. | ||||||||

| 1. The time of the restart delay timer |

|

|

|

|

|

|

|

| 2. Poor contact of the heat exchanger | |

| is shortened. |

|

|

|

|

|

|

|

| sensor. (The connector is | |

| 2. Cool operation |

|

|

|

|

|

|

|

| disconnected.) (CN01) | |

| 3. Air volume [AUTO] |

|

|

|

|

|

|

|

| 3. Heat exchanger sensor, main PC | |

|

|

|

|

|

|

|

|

| board are defective. | ||

| 4. Make the setting temperature lower |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| (Refer to Table | ||

| enough than room temperature. |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| of defective resistance values.) | ||

| 5. Continuous operation. |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| 4. Main PC board is defective. | ||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

6 | The status of No. 5 is continued, | 1. Compressor does not operate. | 1. The temperature of the heat | ||||||||

| and make the following condition. | 2. OPERATION lamp flashes. | exchanger is abnormally high. | ||||||||

| 1. Heat operation |

|

|

|

|

|

|

|

| 2. The heat exchanger sensor | |

| 2. Make the setting temperature |

|

|

|

|

|

|

|

| connector has | |

|

|

|

|

|

|

|

|

| 3. The heat exchanger sensor is | ||

| higher enough than room |

|

|

|

|

|

|

|

| ||

| temperature. |

|

|

|

|

|

|

|

| defective. | |

|

|

|

|

|

|

|

|

|

| (Refer to Table | |

|

|

|

|

|

|

|

|

|

| of defective resistance values.) | |

|

|

|

|

|

|

|

|

|

| 4. PC board is defective. | |

|

|

|

|

|

|

|

|

|

|

| |

7 | Turn the power on after connecting | 1. The voltage of DC 35V is not | 1. Indoor fan motor is defective. | ||||||||

| the motor connector. | measured between the red and | (Protecting operation on the PC | ||||||||

| Start the operation with the following | black of the motor terminals. | board.) | ||||||||

| condition. | 2. Motor does not rotate. | 2. Poor contact of the motor | ||||||||

| 1. Operation [Cooling] | (The key operation is accepted.) | connector. | ||||||||

| 2. Airflow [High fan] | 3. The motor rotates, but it vibrates | 3. PC board is defective. | ||||||||

| 3. Continuous operation | too much. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

– 45 –