P5 |

| Suitable mounting surface |

| ||||

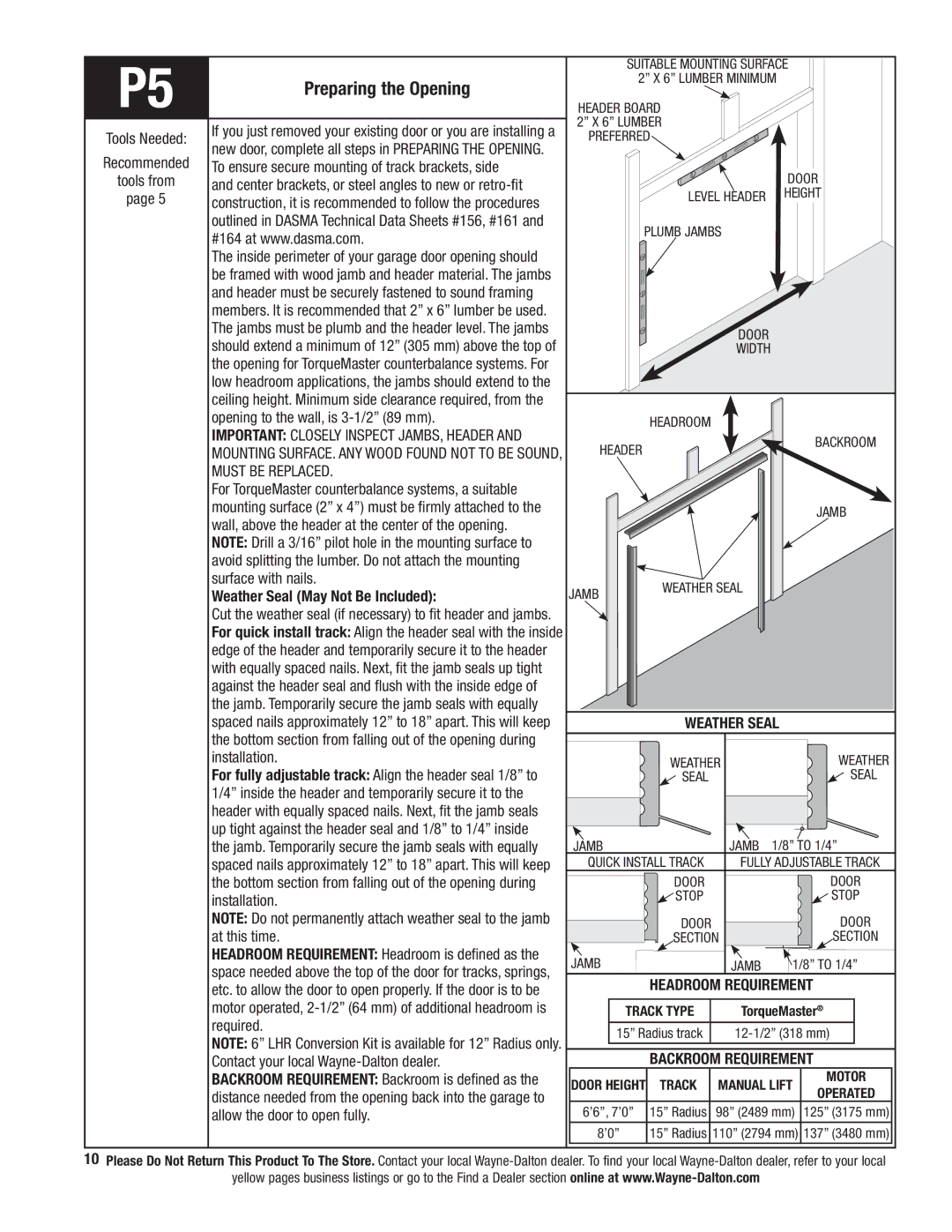

Preparing the Opening | 2” x 6” lumber minimum |

| |||||

|

|

|

|

|

| ||

| Header board |

|

|

|

| ||

| If you just removed your existing door or you are installing a | 2” x 6” lumber |

|

|

|

| |

Tools Needed: | preferred |

|

|

|

| ||

new door, complete all steps in PREPARING THE OPENING. |

|

|

|

| |||

Recommended |

|

|

|

|

|

| |

To ensure secure mounting of track brackets, side |

|

|

|

| Door | ||

tools from | and center brackets, or steel angles to new or |

|

|

|

| ||

page 5 | construction, it is recommended to follow the procedures |

| Level header | height | |||

|

|

| |||||

| outlined in DASMA Technical Data Sheets #156, #161 and | Plumb jambs |

|

|

| ||

| #164 at www.dasma.com. |

|

|

| |||

|

|

|

|

|

|

| |

| The inside perimeter of your garage door opening should |

|

|

|

|

|

|

| be framed with wood jamb and header material. The jambs |

|

|

|

|

|

|

| and header must be securely fastened to sound framing |

|

|

|

|

|

|

| members. It is recommended that 2” x 6” lumber be used. |

|

|

|

|

|

|

| The jambs must be plumb and the header level. The jambs |

|

|

| Door |

|

|

| should extend a minimum of 12” (305 mm) above the top of |

|

|

|

|

| |

|

|

|

| Width |

|

| |

| the opening for TorqueMaster counterbalance systems. For |

|

|

|

|

|

|

| low headroom applications, the jambs should extend to the |

|

|

|

|

|

|

| ceiling height. Minimum side clearance required, from the |

|

|

|

|

|

|

| opening to the wall, is |

| Headroom |

|

|

|

|

| IMPORTANT: Closely inspect jambs, header and | Header |

|

|

|

| Backroom |

| mounting surface. Any wood found not to be sound, |

|

|

|

| ||

|

|

|

|

|

| ||

| must be replaced. |

|

|

|

|

|

|

| For TorqueMaster counterbalance systems, a suitable |

|

|

|

|

|

|

| mounting surface (2” x 4”) must be firmly attached to the |

|

|

|

|

| Jamb |

| wall, above the header at the center of the opening. |

|

|

|

|

| |

|

|

|

|

|

|

| |

| NOTE: Drill a 3/16” pilot hole in the mounting surface to |

|

|

|

|

|

|

| avoid splitting the lumber. Do not attach the mounting |

|

|

|

|

|

|

| surface with nails. | Jamb | WEATHER SEAL |

|

| ||

| Weather Seal (May Not Be Included): |

|

| ||||

|

|

|

|

|

| ||

| Cut the weather seal (if necessary) to fit header and jambs. |

|

|

|

|

|

|

| For quick install track: Align the header seal with the inside |

|

|

|

|

|

|

| edge of the header and temporarily secure it to the header |

|

|

|

|

|

|

| with equally spaced nails. Next, fit the jamb seals up tight |

|

|

|

|

|

|

| against the header seal and flush with the inside edge of |

|

|

|

|

|

|

| the jamb. Temporarily secure the jamb seals with equally |

|

|

|

|

|

|

| spaced nails approximately 12” to 18” apart. This will keep |

| Weather seal |

| |||

| the bottom section from falling out of the opening during |

|

|

|

|

|

|

| installation. |

| Weather |

|

| Weather | |

| For fully adjustable track: Align the header seal 1/8” to |

| seal |

|

|

| seal |

| 1/4” inside the header and temporarily secure it to the |

|

|

|

|

|

|

| header with equally spaced nails. Next, fit the jamb seals |

|

|

|

|

|

|

| up tight against the header seal and 1/8” to 1/4” inside |

|

|

| jamb | 1/8” to 1/4” | |

| the jamb. Temporarily secure the jamb seals with equally | Jamb |

|

| |||

| spaced nails approximately 12” to 18” apart. This will keep | Quick Install Track |

| Fully adjustable Track | |||

| the bottom section from falling out of the opening during |

| Door |

|

|

| Door |

| installation. |

| stop |

|

|

| stop |

|

|

|

|

|

|

| |

| NOTE: Do not permanently attach weather seal to the jamb |

| Door |

|

|

| Door |

| at this time. |

| Section |

|

| Section | |

| HEADROOM REQUIREMENT: Headroom is defined as the | Jamb |

|

| Jamb | 1/8” to 1/4” | |

| space needed above the top of the door for tracks, springs, |

|

| ||||

|

| Headroom requirement |

| ||||

| etc. to allow the door to open properly. If the door is to be |

|

| ||||

|

|

|

|

|

|

| |

| motor operated, | TRACK TYPE |

| TorqueMaster® | |||

| required. | 15” Radius track |

| ||||

| NOTE: 6” LHR Conversion Kit is available for 12” Radius only. |

| |||||

|

| Backroom requirement |

| ||||

| Contact your local |

| MOTOR | ||||

| BACKROOM REQUIREMENT: Backroom is defined as the | DOOR HEIGHT | TRACK | MANUAL LIFT | |||

| distance needed from the opening back into the garage to | OPERATED | |||||

|

|

|

|

|

| ||

| allow the door to open fully. | 6’6”, 7’0” | 15” Radius | 98” (2489 mm) 125” (3175 mm) | |||

|

| 8’0” | 15” Radius 110” (2794 mm) 137” (3480 mm) | ||||

10Please Do Not Return This Product To The Store. Contact your local

yellow pages business listings or go to the Find a Dealer section online at