|

|

| Rear Support Continued... |

|

|

|

|

|

|

| NOTE: If an idrive® opener is installed, |

| Tools Needed: |

| |

|

| position horizontal tracks one hole above | |

|

|

| |

|

|

| level when securing it to rear supports. |

|

|

| |

|

|

| NOTE: Perforated angle must be attached |

|

|

| to sound framing members and nails |

|

|

| should not be used. |

|

|

| Now, lift door and check it’s balance. |

|

|

| Adjust, if door lifts by itself (hard to pull |

|

|

| down) or if door is difficult to lift (easy to |

|

|

| pull down). Anytime spring adjustments |

|

|

| are made, ratchet pawl knob must be in |

|

|

| the upper position to add/remove required |

|

|

| number of spring turns (refer to step 29). |

|

|

| To adjust springs, only add or remove a |

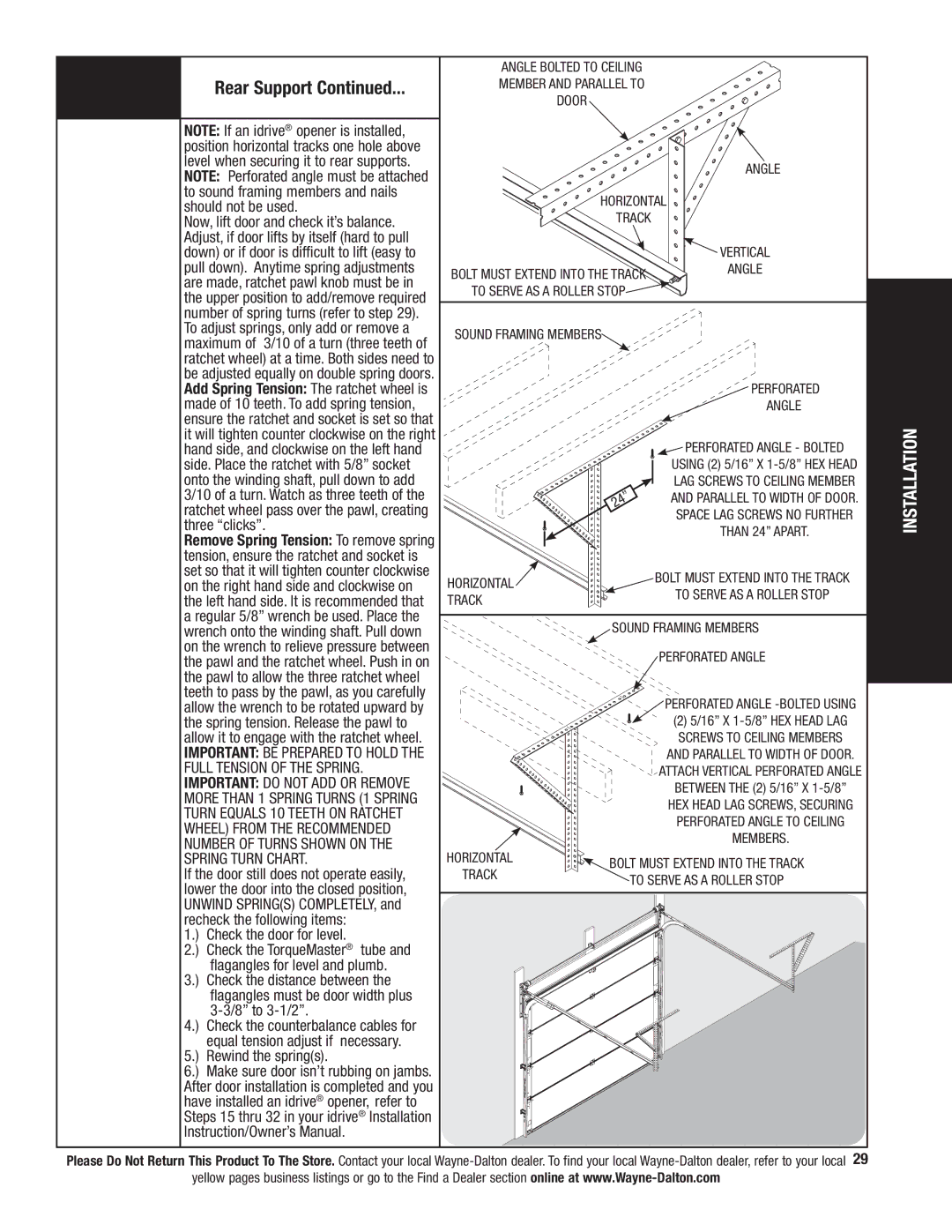

Angle bolted to ceiling member and parallel to door

Horizontal

track

Bolt must extend into the track to serve as a roller stop![]()

Angle

![]() Vertical Angle

Vertical Angle

maximum of 3/10 of a turn (three teeth of | |

ratchet wheel) at a time. Both sides need to | |

be adjusted equally on double spring doors. | |

Add Spring Tension: The ratchet wheel is | |

made of 10 teeth. To add spring tension, | |

ensure the ratchet and socket is set so that | |

it will tighten counter clockwise on the right | |

hand side, and clockwise on the left hand | |

side. Place the ratchet with 5/8” socket | |

onto the winding shaft, pull down to add | |

3/10 of a turn. Watch as three teeth of the | |

ratchet wheel pass over the pawl, creating | |

three “clicks”. | |

Remove Spring Tension: To remove spring | |

tension, ensure the ratchet and socket is | |

set so that it will tighten counter clockwise | |

on the right hand side and clockwise on | |

the left hand side. It is recommended that | |

a regular 5/8” wrench be used. Place the | |

wrench onto the winding shaft. Pull down | |

on the wrench to relieve pressure between | |

the pawl and the ratchet wheel. Push in on | |

the pawl to allow the three ratchet wheel | |

teeth to pass by the pawl, as you carefully | |

allow the wrench to be rotated upward by | |

the spring tension. Release the pawl to | |

allow it to engage with the ratchet wheel. | |

Important: BE PREPARED TO HOLD THE | |

FULL TENSION OF THE SPRING. | |

Important: DO NOT ADD OR REMOVE | |

MORE THAN 1 SPRING TURNS (1 SPRING | |

TURN EQUALS 10 TEETH ON RATCHET | |

WHEEL) FROM THE RECOMMENDED | |

NUMBER OF TURNS SHOWN ON THE | |

SPRING TURN CHART. | |

If the door still does not operate easily, | |

lower the door into the closed position, | |

UNWIND SPRING(S) COMPLETELY, and | |

recheck the following items: | |

1.) | Check the door for level. |

2.) | Check the TorqueMaster® tube and |

| flagangles for level and plumb. |

3.) | Check the distance between the |

| flagangles must be door width plus |

| |

4.) | Check the counterbalance cables for |

| equal tension adjust if necessary. |

5.) | Rewind the spring(s). |

6.) | Make sure door isn’t rubbing on jambs. |

After door installation is completed and you | |

have installed an idrive® opener, refer to | |

Steps 15 thru 32 in your idrive® Installation | |

Instruction/Owner’s Manual. | |

Sound Framing Members

Perforated

ANGLE

![]() Perforated ANGLE - BOLTED USING (2) 5/16” X

Perforated ANGLE - BOLTED USING (2) 5/16” X

LAG SCREWS TO CEILING MEMBER AND PARALLEL TO WIDTH OF DOOR. Space lag screws no further

than 24” apart.

HORIZONTAL | BOLT MUST EXTEND INTO THE TRACK | |

TO SERVE AS A ROLLER STOP | ||

TRACK | ||

| ||

|

| |

| Sound Framing Members |

PERFORATED ANGLE

Perforated ANGLE -BOLTED USING

(2) 5/16” X

AND PARALLEL TO WIDTH OF DOOR. Attach vertical perforated angle between the (2) 5/16” X

HORIZONTAL | BOLT MUST EXTEND INTO THE TRACK | |

TRACK | ||

TO SERVE AS A ROLLER STOP | ||

|

INSTALLATION

Please Do Not Return This Product To The Store. Contact your local