English

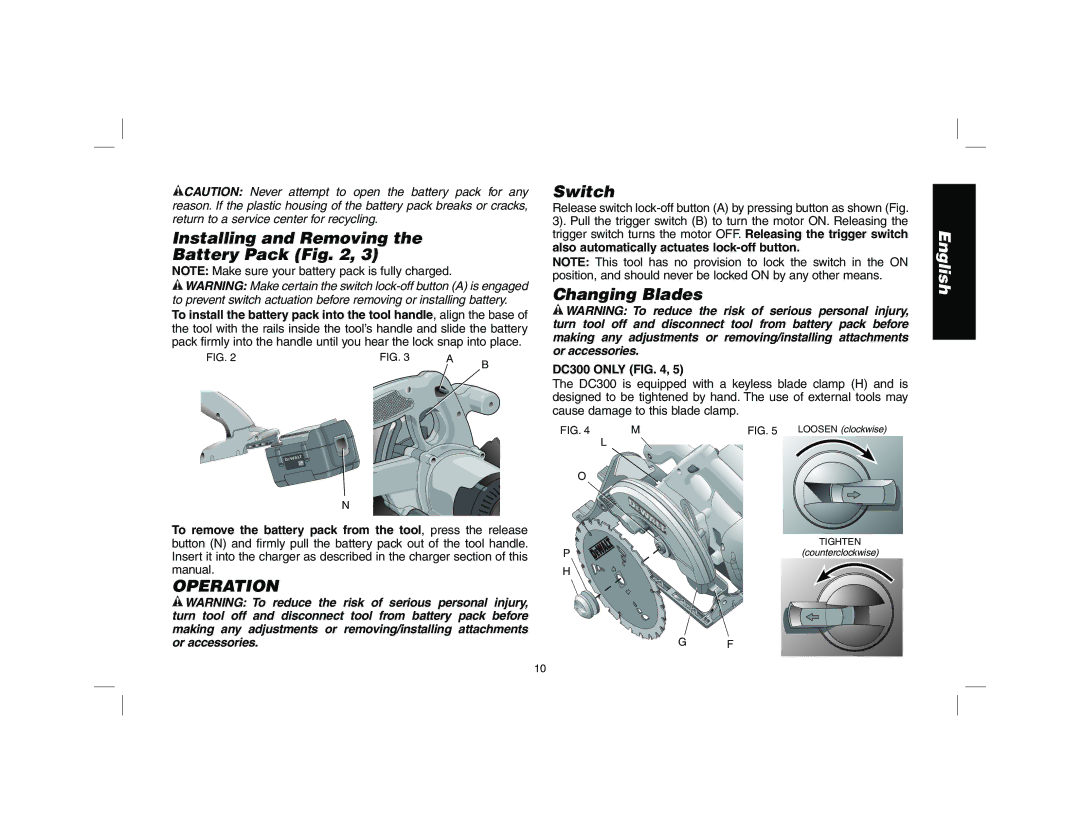

FIG. 14 | FIG. 15 | |||||||||||||||||||||||

DO support board or | DON’T support board or | |||||||||||||||||||||||

panel NEAR the cut. | panel AWAY from the cut. | |||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUPPORT

Workpiece Support

![]() WARNING: It is important to support the work properly and to hold the saw firmly to prevent loss of control which could cause personal injury. Figure 13 illustrates proper hand support of the saw. Maintain a firm grip with both hands on the saw and position your body and arm to allow you to resist kickback if it occurs.

WARNING: It is important to support the work properly and to hold the saw firmly to prevent loss of control which could cause personal injury. Figure 13 illustrates proper hand support of the saw. Maintain a firm grip with both hands on the saw and position your body and arm to allow you to resist kickback if it occurs.

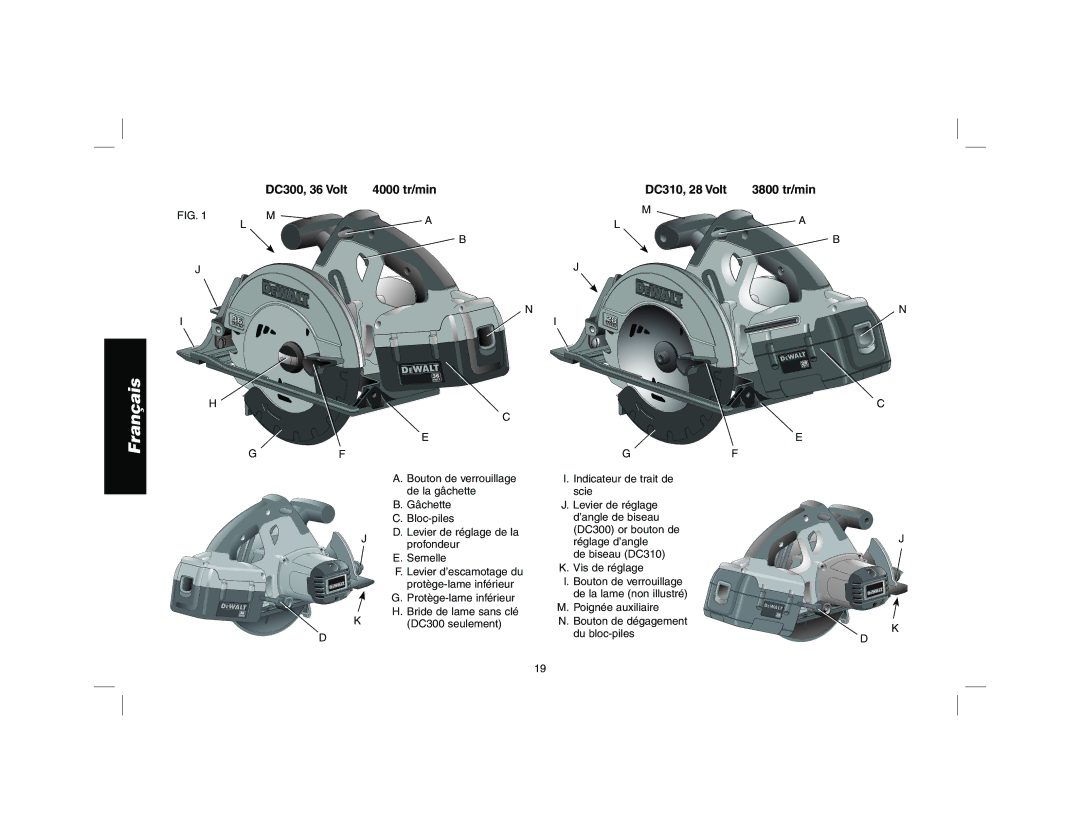

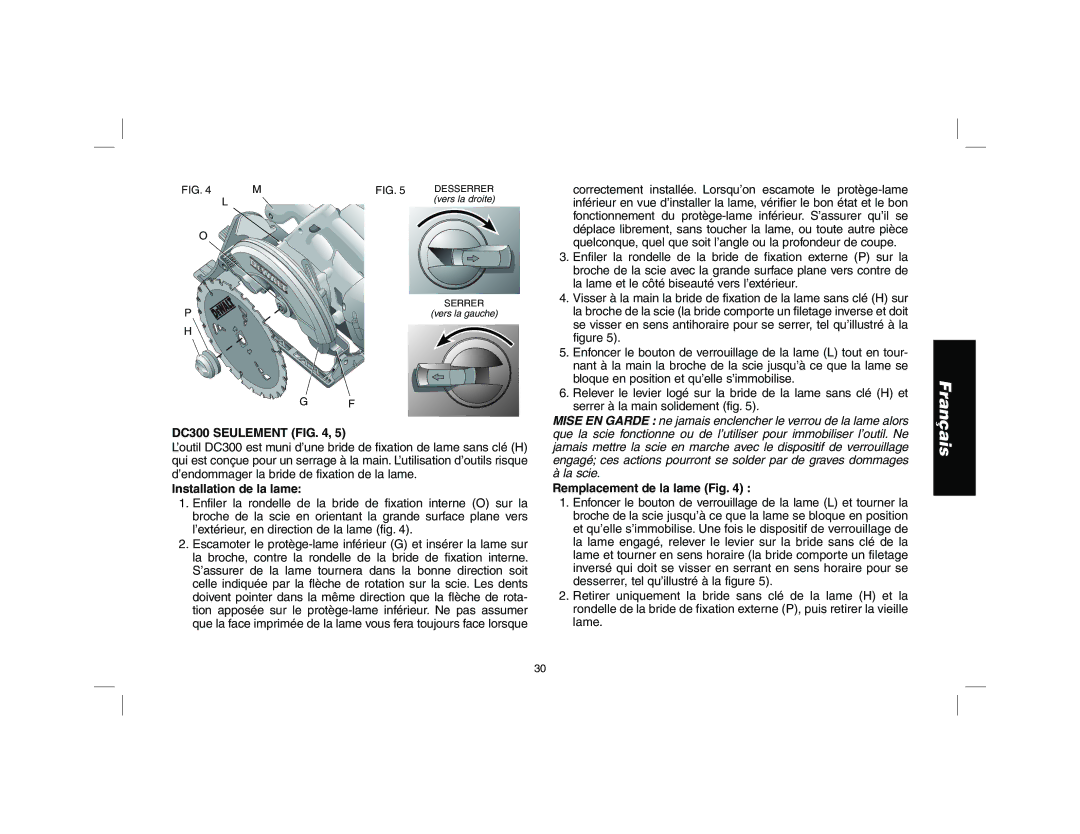

Figure 13 shows proper sawing position. Note that hands are kept away from cutting area. To avoid kickback, DO support board or panel NEAR the cut (Fig. 14). DON’T support board or panel away from the cut (Fig. 15).

Place the work with its “good” side – the one on which appearance is most important – down. The saw cuts upward, so any splintering will be on the work face that is up when you cut it.

Cutting

Place the wider portion of the saw shoe on that part of the workpiece which is solidly supported, not on the section that will fall off when the cut is made. As examples, Figure 13 illustrates the RIGHT way to cut off the end of a board. Always clamp work. Don’t try to hold short pieces by hand! Remember to support cantilevered and overhanging material. Use caution when sawing material from below.

Be sure saw is up to full speed before blade contacts material to be cut. Starting saw with blade against material to be cut or pushed forward into kerf can result in kickback. Push the saw forward at a speed which allows the blade to cut without laboring. Hardness and toughness can vary even in the same piece of material, and knotty or damp sections can put a heavy load on the saw. When this happens, push the saw more slowly, but hard enough to keep working without much decrease in speed. Forcing the saw can cause rough cuts, inaccuracy, kickback, and

IF SAW STALLS, RELEASE THE TRIGGER AND BACK THE SAW UNTIL IT IS LOOSE. BE SURE BLADE IS STRAIGHT IN THE CUT AND CLEAR OF THE CUTTING EDGE BEFORE RESTARTING.

As you finish a cut, release the trigger and allow the blade to stop before lifting the saw from the work. As you lift the saw, the

NOTE: When cutting thin strips, be careful to ensure that small cutoff pieces don’t hang up on inside of lower guard.

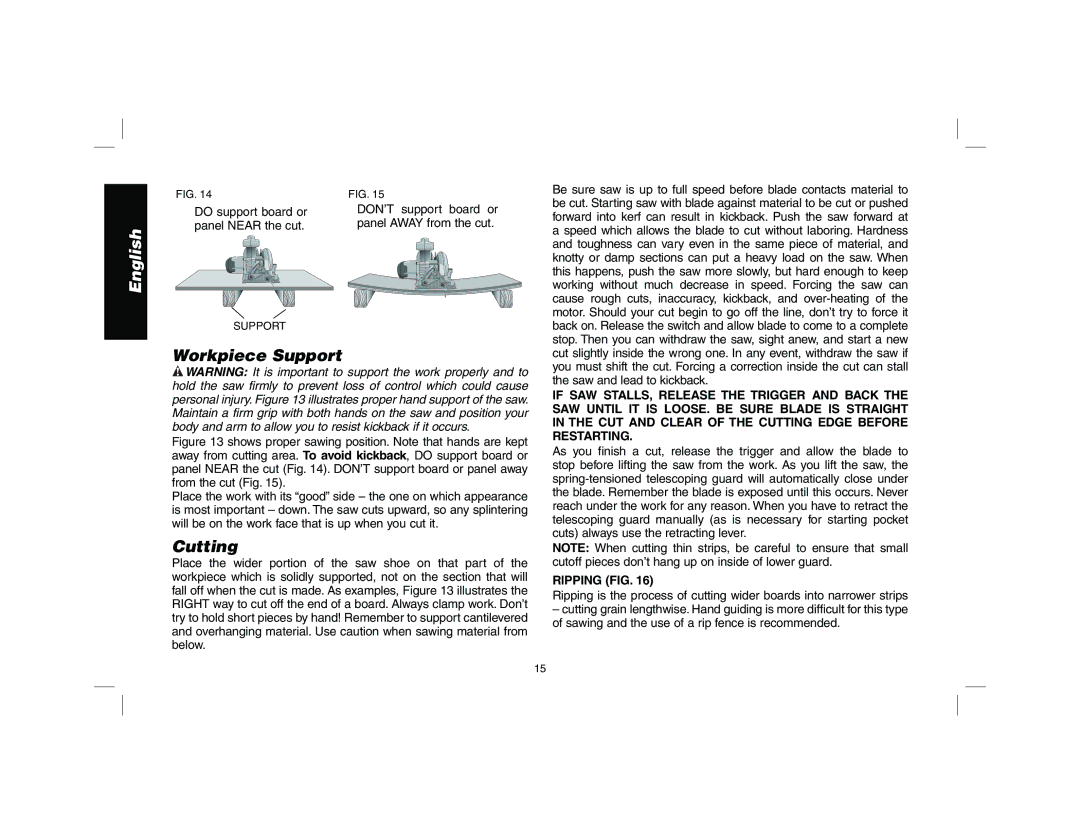

RIPPING (FIG. 16)

Ripping is the process of cutting wider boards into narrower strips

–cutting grain lengthwise. Hand guiding is more difficult for this type of sawing and the use of a rip fence is recommended.

15