Section VIII - Power$ync II™ Operation

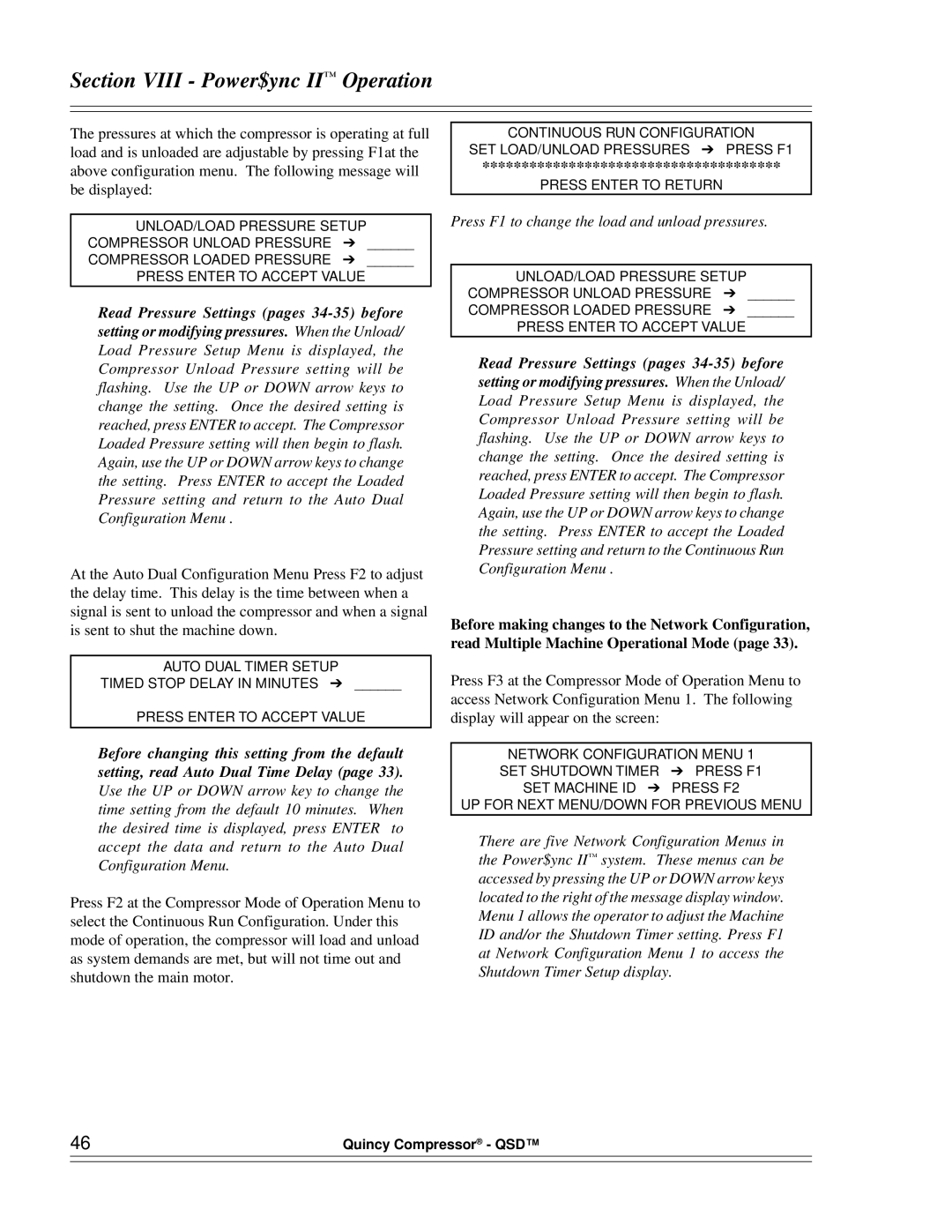

The normal operating displays are dependent on the mode of operation selected. These displays include:

STG 1 OUT TEMP______STG 2 IN TEMP______

COMPRESSOR IS RUNNING IN AUTO DUAL MODE

PRESS ENTER KEY TO SELECT MENU HOURS______STG 2 OUT TEMP______

This display indicates that the compressor is running in the Auto Dual Mode and shows the total number of hours on the machine.

If the system air demand falls below a predetermined minimum, the compressor will unload and start a timer that will count down to shutdown. The following display indicates that condition:

STG 1 OUT TEMP______STG 2 IN TEMP______

COMPRESSOR IS UNLOADED MINUTES LEFT TO SHUTDOWN ➔

HOURS______STG. 2 OUT TEMP______

The countdown display will alert operators that the compressor is detecting little or no system air demand and is operating in the unloaded mode. It also displays the total time left until the unit shuts down and goes into standby mode.

If there is no demand for a predetermined amount of time, the compressor will turn off the main drive (and fan) motor and wait until additional air is required. If additional air usage is detected, the machine will restart automatically. While the compressor is in Standby Mode, the following message will be displayed:

STG 1 OUT TEMP______STG 2 IN TEMP______

COMPRESSOR HAS TIMED OUT AND SHUT DOWN **WARNING** WILL RESTART AUTOMATICALLY WHEN LINE PRESSURE IS______PSIG

Continuous Run Mode is the second primary operational Mode and is identical to Auto Dual Mode except the compressor will not turn itself off and go into Standby Mode. When the system demand falls below a preset minimum, the compressor will unload, but it will continue to run. The following display indicates an unloaded condition:

STG 1 OUT TEMP______STG 2 IN TEMP______

COMPRESSOR IS UNLOADED

HOURS______STG 2 OUT TEMP______

The last of the three primary operational mode displays indicates that the compressor has been setup to run with other Power$ync II™ machines in a network. This Network Mode allows several machines to work together to deliver the greatest number of CFM for the least amount of power input. The following display indicates that the compressor has been setup for this type of operation:

STG 1 OUT TEMP______STG 2 IN TEMP______

RUNNING IN NETWORK MODE POSITION___ OF___

PRESS ENTER KEY TO SELECT MENU

HOURS______STG 2 OUT TEMP______

Besides indicating that the machine is running in a network, this display also indicates the position in that network assigned to this particular unit. Units running in Network Mode will load, unload and shutdown similar to Auto Dual Mode.

The following display in the operational group indicates that SHUTDOWN has been pressed.

STG 1 OUT TEMP______STG 2 IN TEMP______

PROGRAMMED SHUTDOWN

HOURS______STG 2 OUT TEMP______

If Continuous Run Mode has been selected, the following message will be displayed after the compressor is started:

STG 1 OUT TEMP______STG 2 IN TEMP______

RUNNING IN CONTINUOUS RUN MODE PRESS ENTER KEY TO SELECT MENU HOURS______STG 2 OUT TEMP______

This display indicates that the compressor has been intentionally turned off and has not experienced an emergency shutdown. When SHUTDOWN is pressed, the controller will open the bypass valves to unload the compressor and then open the blowdown valve to vent the pressure in the system piping. When the pressure has been vented, the

44 | Quincy Compressor® - QSD™ |

|

|