Agilent 86120C Multi-Wavelength Meter User’s Guide

Second Edition 86120-90C03 August

Characterize laser lines easily

Agilent 86120C-At a Glance

Program the instrument for automatic measurements

Print measurement results

Measurement accuracy-it’s up to you

There is no output laser aperture

General Safety Considerations

WA R N I N G

Viii

Contents

Performance Tests

Contents-3

Page

Getting Started

Getting Started

Measurement accuracy-it’s up to you

Inspect the Shipment

Line Power Requirements

Connect the Line- Power Cable

Connect a Printer

Instrument firmware version

Turn on the Agilent 86120C

Converting feet to meters

Enter Your Elevation

Definition of standard air

Select Medium for Wavelength Values

Turn Off Wavelength Limiting

Returning the Instrument for Service

Preparing the instrument for shipping

Returning the Instrument for Service

Returning the Instrument for Service

Returning the Instrument for Service

Page

Making Measurements

Making Measurements

This section includes

Measuring Wavelength and Power

To display peak wavelength and power

Peak WL mode

Measuring Wavelength and Power

To display multiple laser lines

List by WL or Power modes

Total power and average wavelength

To display average wavelength and total power

Limiting the wavelength measurement range

To limit the wavelength range

To measure broadband devices

Measuring broadband devices and chirped lasers

Graphical display of optical power spectrum

To see the graphical display

Agilent 86120C graphical display

To control the power bar

Power bar

Instrument states

To save an instrument state

Displayed units

Changing the Units and Measurement Rate

To change the units of measure

Available Units

Measurement rate

Continuous or single measurements

To change the measurement speed

To select single measurement acquisition

Defining Laser- Line Peaks

To define laser- line peaks

If too many lines are identified

Measuring Laser Separation

Channel separation

To measure channel separation

To measure flatness

Measuring flatness

Measuring Laser Drift

If measurement updating stops or the values become blanked

To measure drift

Measuring Laser Drift

Signal-to-noise display

Measuring Signal- to- Noise Ratios

Location of noise measurements

Repetitive data formats

Automatic interpolation

To measure signal- to- noise

Signal-to-noise with averaging display

Measuring Signal- to- Noise Ratios with Averaging

Press List by WL or List by Power

To measure signal- to- noise with averaging

To characterize a Fabry- Perot laser

Measuring Fabry- Perot FP Lasers

P

PWR

Measuring Modulated Lasers

Prbs modulation graph showing raised noise floor

To measure total power exceeding 10 dBm

Measuring Total Power Greater than 10 dBm

Calibrating Measurements

To select the medium for light

To enter the elevation

To create a hardcopy

Printing Measurement Results

Choosing the Right Connector

Cleaning Connections for Accurate Measurements

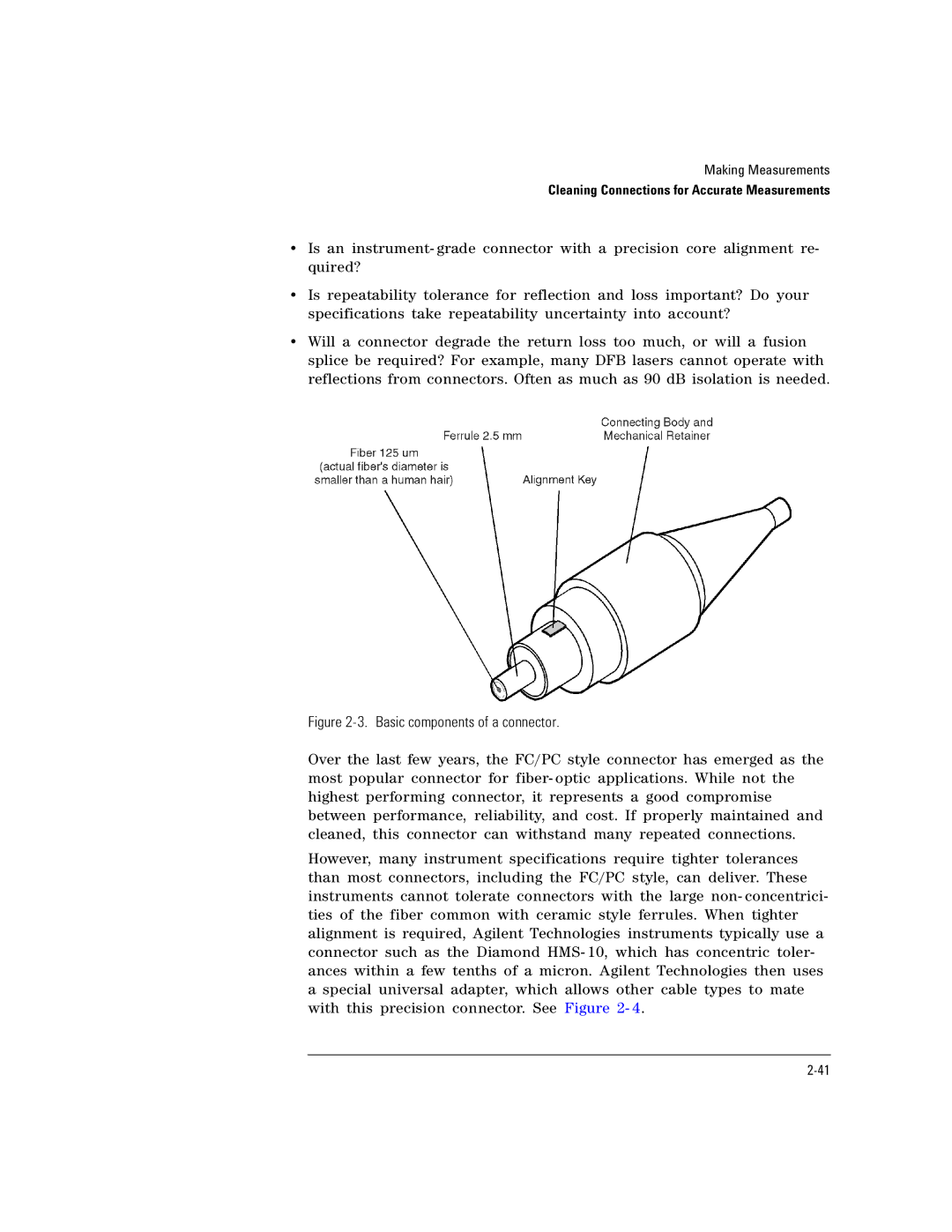

Basic components of a connector

Universal adapters to Diamond HMS-10

Inspecting Connectors

Clean, problem-free fiber end and ferrule

Damage from improper cleaning

Measuring insertion loss and return loss

Visual inspection of fiber ends

Cleaning Connectors

To clean a non- lensed connector

Cleaning Accessories

Dust Caps Provided with Lightwave Instruments

Universal adapters

To clean an adapter

Cleaning Connections for Accurate Measurements

Programming

Types of commands

Where to begin…

Remote mode and front- panel lockout

Addressing and Initializing the Instrument

Initialize the instrument at start of every program

To change the Gpib address

Set single acquisition mode

Making Measurements

Making Measurements

Unit

Commands are grouped in subsystems

Commands for Capturing Data

MEASure command

Measurement instructions give quick results

Different Forms of MEASure

FETCh command

Read command

Return single or multiple measurement values

CONFigure command

ARRay and the Scpi standard

Or, the *WAI command could be used

Measure delta, drift, and signal- to- noise

Measurements are returned as strings

Format of returned data

Determine the number of data points

Data can be corrected for elevation and vacuum

Monitoring the Instrument

Status Byte register

Status registers

Monitoring the Instrument

Bits in Operation Status Register

OPERation Status and QUEStionable Status registers

Standard Event Status register

Bits in Questionable Status Register

Enabling register bits with masks

Error queue

Queues

Output queue

Sending a command

Scpi command are grouped in subsystems

Reviewing Scpi Syntax Rules

Use either short or long forms

Examples of Short Forms

Combine commands in the same subsystem

Equivalent Short Form

You can use upper or lowercase letters

Sending common commands

Combine commands from different subsystems

Adding parameters to a command

White space

Suffix Multipliers

28E2 280E-1 28000m 028K 28E-3K

Querying data

Program message terminator

Example Programs

Errormsg subroutine

Many subroutines are repeated in the examples

Setese subroutine

Errmngmt subroutine

FNIdentity function

Cmdopc subroutine

Tempo subroutine

Example 1. Measure a DFB laser

OFF Timeout

Fnend

Example 2. Measure WDM channels

COM /Instrument/ @Mwm Output @Mwm *ESEIVAL00110100,2

Query the number of data points

Example 3. Measure WDM channel drift

Turn off drift reference state

CmdopcSUB CmdopcSetcmd$

Query number of data points

Example 4. Measure WDM channel separation

Next

Turn signal-to-noise ratio on

Next Stop

Example 6. Increase a source’s wavelength accuracy

Set wavelength of tunable laser source

10. Programming Commands 1

Lists of Commands

10. Programming Commands 2

10. Programming Commands 3

Frequency DISPlayMARKerMAXimumNEXT

10. Programming Commands 4

AIR SENSeDATA?

∆ WL

11. Keys Versus Commands 1

11. Keys Versus Commands 2

Lists of Commands

Programming Commands

12. Notation Conventions and Definitions

Programming Commands

CLS

Common Commands

13. Event Status Enable Register

Query Response

Example

14. Standard Event Status Register

ESR?

IDN?

OPC

RST

15. Conditions Set by *RST Reset 1

SAV

15. Conditions Set by *RST Reset 2

SRE

16. Service Request Enable Register

Integer from 0 to 63 or from 128 to

17. Status Byte Register

STB?

TRG

WAI

Measurement Instructions

POWer? FREQuency? WAVelength? WNUMber?

CONFigure command

MEASureARRay SCALar POWer?

Displays the highest power signal

MINimum Displays the lowest power signal DEFault

88346500E+000

MINimum

MEASureARRay SCALar POWerFREQuen- cy?

DEFault Current marker position

MAXimum Resolution fast update

MINimum Resolution normal DEFault Current resolution

MEASureARRay SCALar POWerWAVe- length?

MEASSCALPOWWAV? MAX is sent

MEASureARRay SCALar POWerWNUMber?

If the MEASSCALPOWWNUM? 6451 command is sent, and a

FREQuency POINts

CALCulate1 Subsystem

DATA?

Frequency = 181,6915 THz + 2, 9993,613378 GHz = 192,5280 THz

CALCulate1 Subsystem

TRANsformFREQuencyPOINts

Non-sequential command

Constant Description MINimum 525 MAXimum 15,047

3-12 for more information

For normal update

STATe

CALCulate2 Subsystem

STATe STARt FREQuency WAVelength WNUMber

FREQuency WAVelength WNUMber

Weighted average wave number is returned

POWer

Constant Description FREQuency

Average frequency is returned

Syntax

PEXCursion

Attribute

Summary

POINts?

PTHReshold

Constant Value MINimum MAXimum 40 dB

PWAVerageSTATe

DEFault 10 dB

CALCulate2 Subsystem

WLIMitSTATe

3-12for more information

WLIMitSTARtFREQuency

WLIMitSTARtWAVelength

WLIMitSTARtWNUMber

WLIMitSTOPFREQuency

WLIMitSTOPWAVelength

WLIMitSTOPWNUMber

DIFFerence STATe MAXimum MINimum PRESet REFerence

CALCulate3 Subsystem

CLEar COUNt STATe

WAVelength? FREQuency? WNUMber? POWer? SIGMa

WAVelength? FREQuency? WNUMber?

REFerence FREQuency WAVelength WNUMber STATe

ASNRCLEar

Constant Description MINimum MAXimum 900

ASNRCOUNt

Tion on selecting measurements

ASNRSTATe

Argument Description POWer

Completed

Is completed

DELTaPRESet

DELTaPOWerSTATe

DELTaREFerencePOWer?

DELTaREFerenceFREQuency

Constant

DELTaREFerenceWAVelength

Measurement

DELTaREFerenceWNUMber

An absolute frequency unnormalized

DELTaWAVelengthSTATe

DELTaWPOWerSTATe

DRIFtDIFFerenceSTATe

DRIFtMAXimumSTATe

Imum power and frequency

DRIFtMINimumSTATe

Imum power or frequency

DRIFtREFerenceRESet

DRIFtPRESet

DRIFtREFerenceSTATe

DRIFtSTATe

FPERotFWHM?

FPERotSTATE

Argument Description WAVelength

Modes

FPERotMEAN?

FPERotMODESPACing?

Watts

FPERotPEAK?

Argument Description

FPERotPOWer?

DBm DBM

Watts WATTs

FPERotSIGMa?

PRESet

Selects user-entered reference frequency

Snrauto

SNRREFerenceFREQuency

SNRREFerenceWAVelength

SNRREFerenceWNUMber

SNRSTATe

CONFigure Measurement Instruction

DISPlay Subsystem

PREVious RIGHt

GRAPhics STATe

MARKerMAXimumLEFT

MARKerMAXimum

MARKerMAXimumPREVious

MARKerMAXimumNEXT

WINDowGRAPhicsSTATe

MARKerMAXimumRIGHt

FETCh Measurement Instruction

IMMediate

HCOPy Subsystem

MEASure Measurement Instruction

Read Measurement Instruction

DEVice ELEVations MEDium OFFSet MAGNitude

SENSe Subsystem

Constant Description NARRow

CORRectionDEVice

As DFB lasers and modes of FP lasers

BROad

0Description

CORRectionELEVation

CORRectionMEDium

Selects wavelength values in standard air

VACuum Selects wavelength values in a vacuum

CORRectionOFFSetMAGNitude

For 30 or 40 seconds

000,+1.48632800E+000,+1.50488300E+000

STATus Subsystem

CONDition? ENABle EVENt? PTRansition NTRansition

OPERation QUEStionableCONDition?

OPERation QUEStionableENABle

OPERation QUEStionableEVENt

OPERation QUEStionableNTRansition

OPERation QUEStionablePTRansition

18. Preset Values

HEADers?

SYSTem Subsystem

ERRor

Can only be sent as a query

HELPHEADers?

19. Instrument Conditions 1

19. Instrument Conditions 2

20. Scpi Version Numbers

VERSion

TRIGger Subsystem

ABORt

INITiateCONTinuous

INITiateIMMediate

Unit Subsystem

POWer

108

Performance Tests

Calibration Cycle

Performance Tests

Test 1. Absolute Wavelength Accuracy

Be damaged when total input power exceeds 18 dBm

Test 2. Sensitivity

Test 3. Polarization Dependence

Test 4. Optical Input Return Loss

Procedure Standard instruments flat contacting connectors

Regulatory Information

FC/APC patchcord loss

Polarization sensitivity

Test 5. Amplitude Accuracy and Linearity

Linearity = Power Meter Reading 86120C Power Reading offset

21. Linearity Data Values

Page

Specifications and Regulatory Information

Specifications and Regulatory Information

Definition of Terms

Wavelength

Amplitude

Sensitivity

Input Power

Selectivity

Maximum Number

Display resolution 001 nm

Specifications-NORMAL Update Mode

Amplitude

Sensitivity

Selectivity

Input Return Loss

Measurement Cycle Time

Measurement Applications

Specifications-FAST Update Mode

Amplitude

Fast update mode characteristic S 2 measurements-per-second

Operating Specifications

Operating Specifications

Laser Safety Information

Laser Safety

Please pay attention to the following laser safety warnings

Acoustic Noise Emission Geräuschemission

Compliance with Canadian EMC Requirements

Declaration of Conformity

Front view of instrument Rear view of instrument

Product Overview

Product Overview

Reference

Reference

22. Instrument Preset Conditions 1

Key Pressed Turned On

22. Instrument Preset Conditions 2

Menu Maps

Appl’s Menu

There is no menu associated with this key

Display List by Power Menu

Display List by WL Menu Delta On Menu

There is no menu associated with this key

System Print Menu

System Setup Menu

23. Instrument Specific Error Messages 1

Error Messages

23. Instrument Specific Error Messages 2

23. Instrument Specific Error Messages 3

Error Number Description

24. General Scpi Error Messages 1

213 Init ignored

24. General Scpi Error Messages 2

24. General Scpi Error Messages 3

Front-Panel Fiber-Optic Adapters

Power Cords

Agilent Technologies Service Numbers

Page

Index

Index

Index-3

Index-4

Index-5

Index-6

Index-7

Page

Page

Agilent Technologies