Operators Manual

ALS 230

A mechanical sensor is limited in the speed. The bounce at the label edges produces wrong signals.

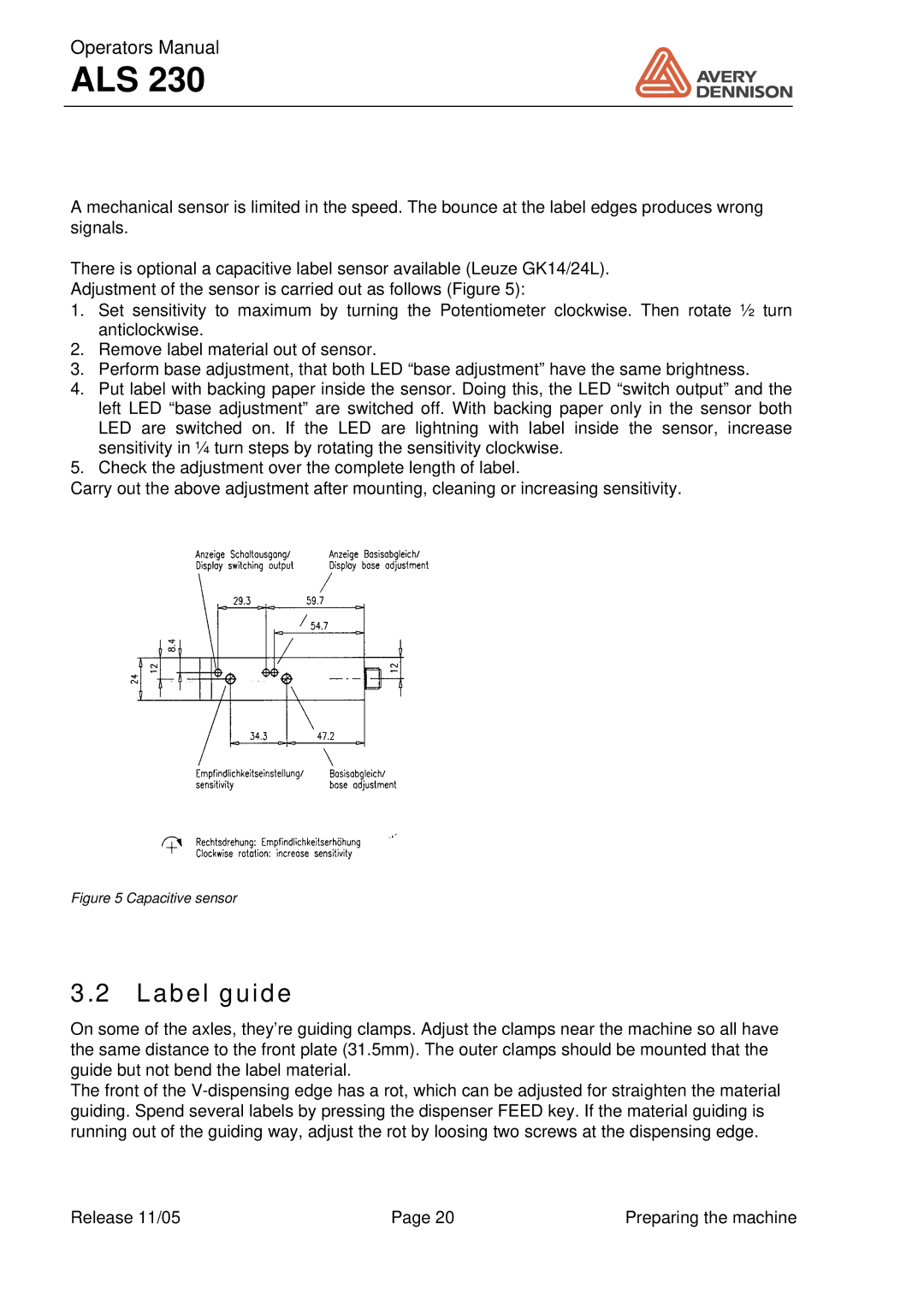

There is optional a capacitive label sensor available (Leuze GK14/24L).

Adjustment of the sensor is carried out as follows (Figure 5):

1.Set sensitivity to maximum by turning the Potentiometer clockwise. Then rotate ½ turn anticlockwise.

2.Remove label material out of sensor.

3.Perform base adjustment, that both LED “base adjustment” have the same brightness.

4.Put label with backing paper inside the sensor. Doing this, the LED “switch output” and the left LED “base adjustment” are switched off. With backing paper only in the sensor both LED are switched on. If the LED are lightning with label inside the sensor, increase sensitivity in ¼ turn steps by rotating the sensitivity clockwise.

5.Check the adjustment over the complete length of label.

Carry out the above adjustment after mounting, cleaning or increasing sensitivity.

Figure 5 Capacitive sensor

3.2 Label guide

On some of the axles, they’re guiding clamps. Adjust the clamps near the machine so all have the same distance to the front plate (31.5mm). The outer clamps should be mounted that the guide but not bend the label material.

The front of the

Release 11/05 | Page 20 | Preparing the machine |