Operators Manual

ALS 230

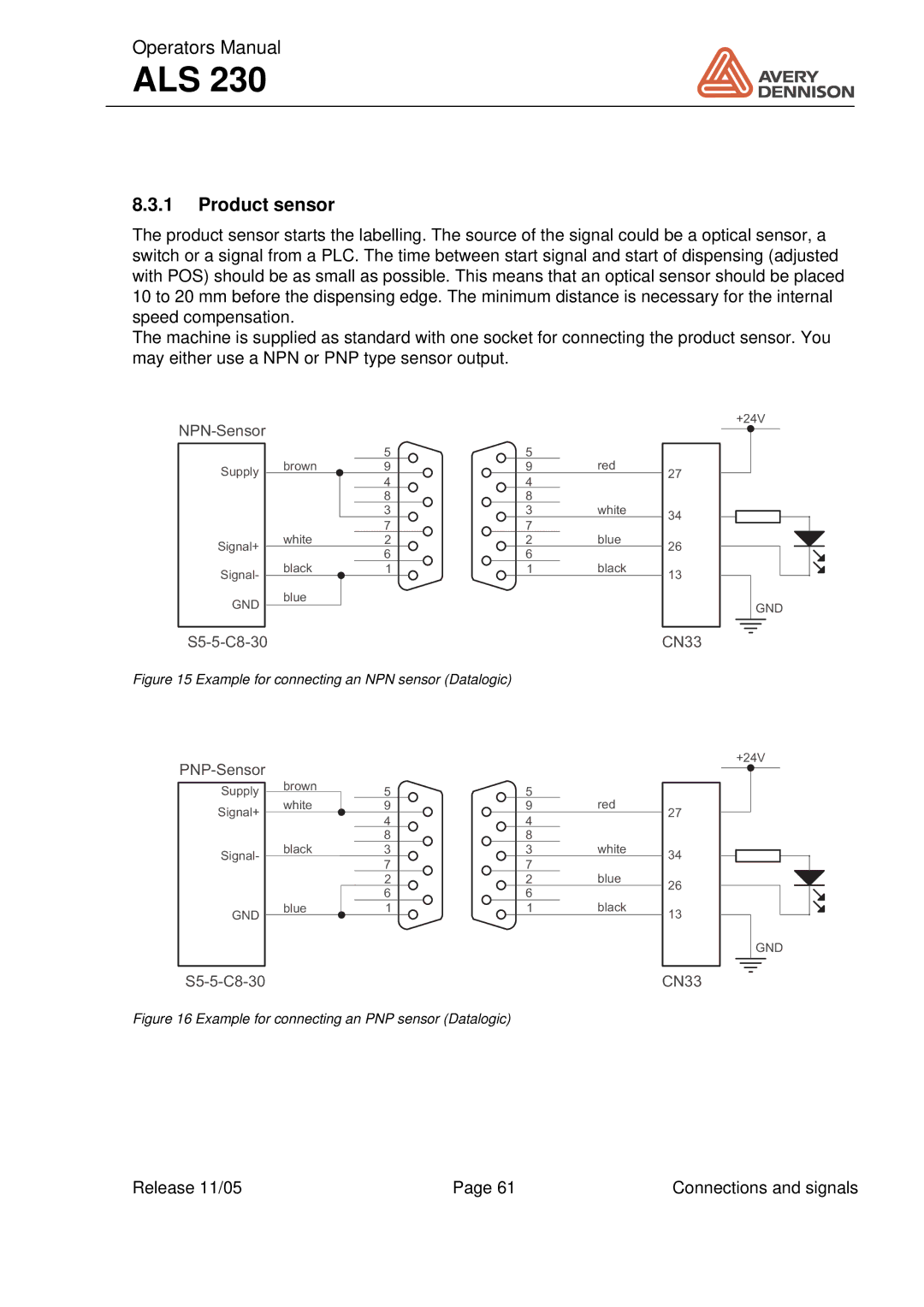

8.3.1Product sensor

The product sensor starts the labelling. The source of the signal could be a optical sensor, a switch or a signal from a PLC. The time between start signal and start of dispensing (adjusted with POS) should be as small as possible. This means that an optical sensor should be placed 10 to 20 mm before the dispensing edge. The minimum distance is necessary for the internal speed compensation.

The machine is supplied as standard with one socket for connecting the product sensor. You may either use a NPN or PNP type sensor output.

Supply

Signal+

Signal-

GND

| 5 | 5 |

|

brown | 9 | 9 | red |

| 4 | 4 |

|

| 8 | 8 |

|

| 3 | 3 | white |

| 7 | 7 |

|

white | 2 | 2 | blue |

| 6 | 6 |

|

black | 1 | 1 | black |

blue

27

34

26

13

+24V

GND

Figure 15 Example for connecting an NPN sensor (Datalogic)

CN33

+24V

Supply

Signal+

Signal-

GND

brown

white

black

blue

5 | 5 |

|

9 | 9 | red |

4 | 4 |

|

8 | 8 |

|

3 | 3 | white |

7 | 7 |

|

2 | 2 | blue |

6 | 6 |

|

1 | 1 | black |

27

34

26

13

GND

Figure 16 Example for connecting an PNP sensor (Datalogic)

CN33

Release 11/05 | Page 61 | Connections and signals |