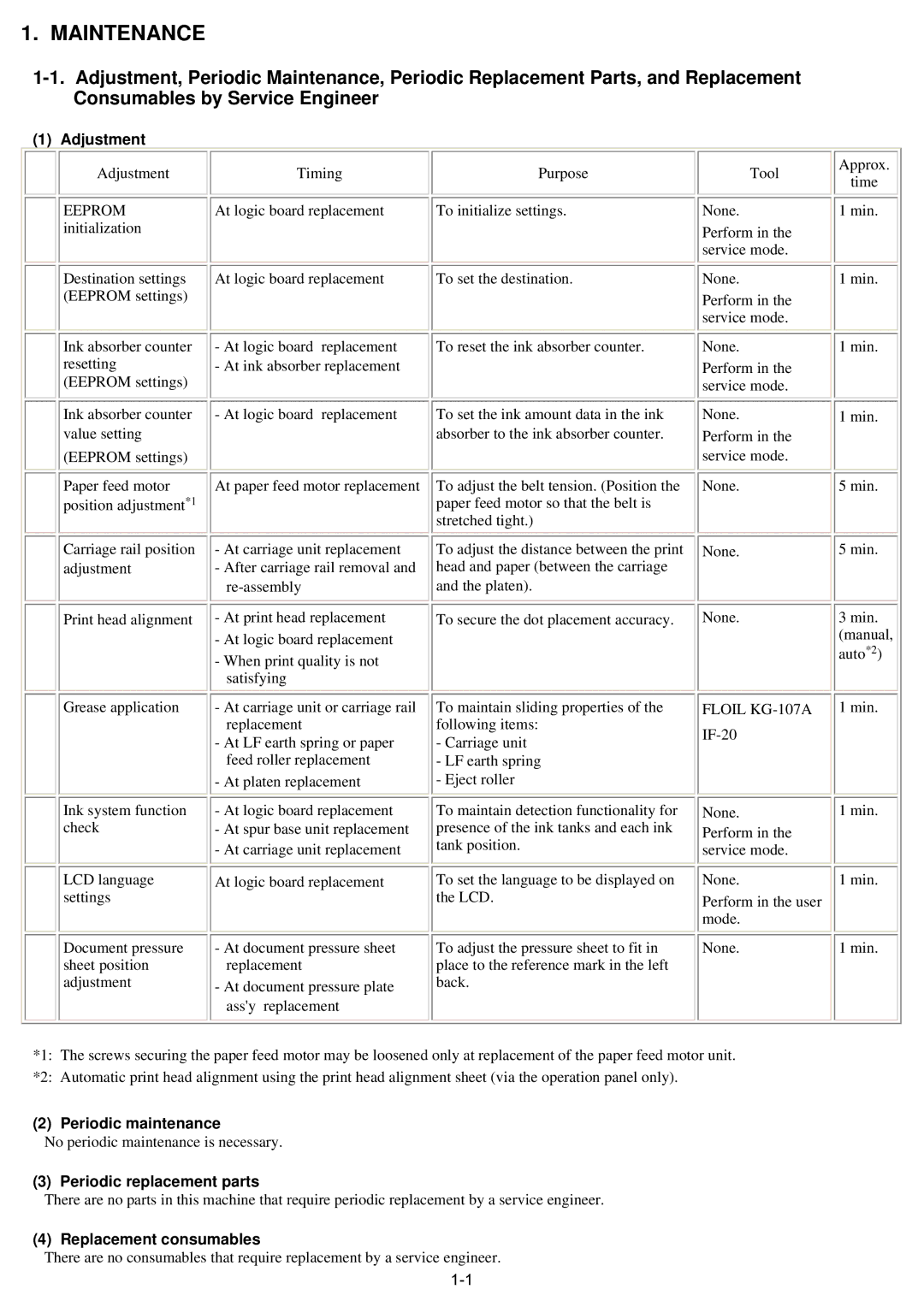

1. MAINTENANCE

(1) Adjustment |

|

|

|

Adjustment | Timing | Purpose | Tool |

EEPROM | At logic board replacement | To initialize settings. | None. |

initialization |

|

| Perform in the |

|

|

| service mode. |

Approx.

time

1 min. |

Destination settings | At logic board replacement |

(EEPROM settings) |

|

Ink absorber counter | - At logic board replacement |

resetting | - At ink absorber replacement |

(EEPROM settings) |

|

Ink absorber counter | - At logic board replacement |

value setting |

|

(EEPROM settings) |

|

Paper feed motor | At paper feed motor replacement |

position adjustment*1 |

|

Carriage rail position | - At carriage unit replacement |

adjustment | - After carriage rail removal and |

| |

Print head alignment | - At print head replacement |

| - At logic board replacement |

| - When print quality is not |

| satisfying |

Grease application | - At carriage unit or carriage rail |

| replacement |

| - At LF earth spring or paper |

| feed roller replacement |

| - At platen replacement |

Ink system function | - At logic board replacement |

check | - At spur base unit replacement |

| - At carriage unit replacement |

LCD language | At logic board replacement |

settings |

|

To set the destination.

To reset the ink absorber counter.

To set the ink amount data in the ink absorber to the ink absorber counter.

To adjust the belt tension. (Position the paper feed motor so that the belt is stretched tight.)

To adjust the distance between the print head and paper (between the carriage

and the platen).

To secure the dot placement accuracy.

To maintain sliding properties of the following items:

-Carriage unit

-LF earth spring

-Eject roller

To maintain detection functionality for presence of the ink tanks and each ink tank position.

To set the language to be displayed on the LCD.

None.

Perform in the service mode.

None.

Perform in the service mode.

None. Perform in the service mode.

None.

None.

None.

FLOIL KG-107A IF-20

None.

Perform in the service mode.

None.

Perform in the user mode.

1 min. |

1 min. |

1 min. |

5min.

5min.

3min.

(manual, auto*2)

1 min.

1 min. |

1 min. |

Document pressure | - At document pressure sheet | To adjust the pressure sheet to fit in | None. |

sheet position | replacement | place to the reference mark in the left |

|

adjustment | - At document pressure plate | back. |

|

| ass'y replacement |

|

|

1 min. |

*1: The screws securing the paper feed motor may be loosened only at replacement of the paper feed motor unit.

*2: Automatic print head alignment using the print head alignment sheet (via the operation panel only).

(2) Periodic maintenance

No periodic maintenance is necessary.

(3) Periodic replacement parts

There are no parts in this machine that require periodic replacement by a service engineer.

(4) Replacement consumables

There are no consumables that require replacement by a service engineer.