PIC System Functions

NOTE: Throughout this manual, words printed in capital let- ters and italics represent values that may be viewed on the LID. See Table 2 for examples of LID screens. Point names are listed in the Description column. An overview of LID operation and menus is given in Fig. 13-19.

CAPACITY CONTROL Ð The PIC controls the chiller capacity by modulating the inlet guide vanes in response to chilled water temperature changes away from the CON- TROL POINT. The CONTROL POINT may be changed by a CCN network device, or is determined by the PIC adding any active chilled water reset to the ECW (Entering Chilled Water) SET POINT or LCW SET POINT. The PIC uses the PROPORTIONAL INC (Increase) BAND, PROPORTIONAL DEC (Decrease) BAND, and the PROPORTIONAL ECW GAIN to determine how fast or slow to respond. CONTROL POINT may be viewed/overridden on the Status table, Status01 selection.

ENTERING CHILLED WATER CONTROL Ð If this op- tion is enabled, the PIC uses ENTERING CHILLED WATER temperature to modulate the vanes instead of LEAV- ING CHILLED WATER temperature. ENTERING CHILLED WATER control option may be viewed/modi®ed on the Equip- ment Con®guration table, Con®g table.

DEADBAND Ð This is the tolerance on the chilled water/ brine temperature CONTROL POINT. If the water temper- ature goes outside of the DEADBAND, the PIC opens or closes the guide vanes in response until it is within tolerance. The PIC may be con®gured with a 0.5 to 2 F (0.3 to 1.1 C) dead- band. DEADBAND may be viewed or modi®ed on the Equip- ment Service1 table.

For example, a 1° F (0.6° C) deadband setting controls the water temperature within ±0.5° F (0.3° C) of the con- trol point. This may cause frequent guide vane movement if the chilled water load ¯uctuates frequently. A value of 1° F (0.6° C) is the default setting.

PROPORTIONAL BANDS AND GAIN Ð Proportional band is the rate at which the guide vane position is corrected in proportion to how far the chilled water/brine temperature is from the control point. Proportional gain determines how quickly the guide vanes react to how quickly the tempera- ture is moving from CONTROL POINT.

The proportional band can be viewed/modi®ed on the LID. There are two response modes, one for temperature re- sponse above the control point, the other for response below the control point.

The ®rst type is called PROPORTIONAL INC BAND, and it can slow or quicken vane response to chilled water/ brine temperature above DEADBAND. It can be adjusted from a setting of 2 to 10; the default setting is 6.5. PRO- PORTIONAL DEC BAND can slow or quicken vane re- sponse to chilled water temperature below deadband plus control point. It can be adjusted on the LID from a setting of 2 to 10, and the default setting is 6.0. Increasing either of these set- tings will cause the vanes to respond slower than at a lower setting.

The PROPORTIONAL ECW GAIN can be adjusted at the LID display from a setting of 1.0 to 3.0, with a default setting of

2.0.Increase this setting to increase guide vane response to a change in entering chilled water temperature. The propor- tional bands and gain may be viewed/modi®ed on the Equip- ment Service3 table.

DEMAND LIMITING Ð The PIC will respond to the ACTIVE DEMAND LIMIT set point by limiting the open- ing of the guide vanes. It will compare the set point to either COMPRESSOR MOTOR LOAD or COMPRES- SOR MOTOR CURRENT (percentage), depending on how the control is con®gured for the DEMAND LIMIT SOURCE which is accessed on the SERVICE1 table. The default set- ting is current limiting.

CHILLER TIMERS Ð The PIC maintains 2 runtime clocks, known as COMPRESSOR ONTIME and SERVICE ON- TIME. COMPRESSOR ONTIME indicates the total life- time compressor run hours. This timer can register up to 500,000 hours before the clock turns back to zero. The SERVICE ONTIME is a resettable timer that can be used to indicate the hours since the last service visit or any other reason. The time can be changed through the LID to whatever value is desired. This timer can register up to 32,767 hours before it rolls over to zero.

The chiller also maintains a start-to-start timer and a stop- to-start timer. These timers limit how soon the chiller can be started. See the Start-Up/Shutdown/Recycle Sequence sec- tion, page 39, for operational information.

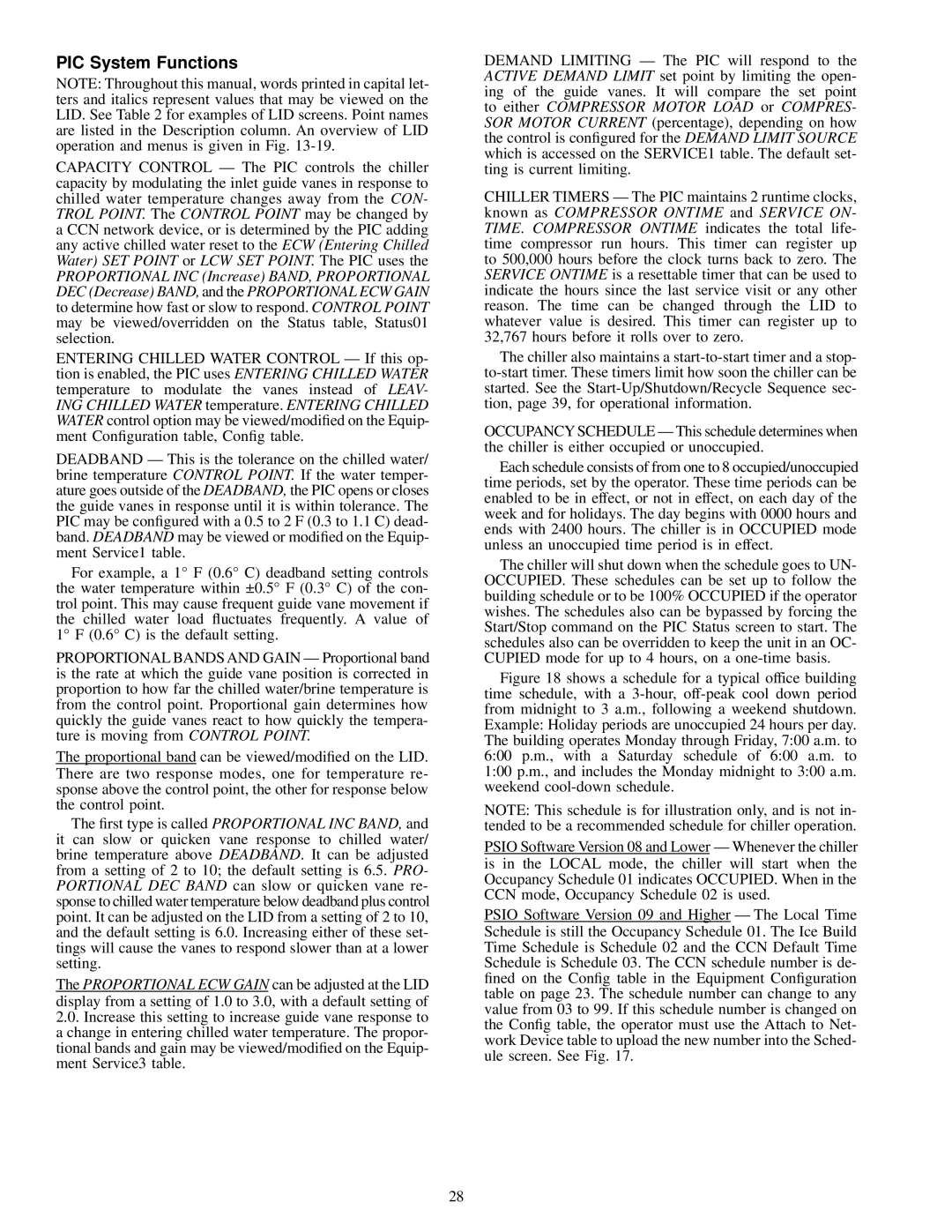

OCCUPANCY SCHEDULE Ð This schedule determines when the chiller is either occupied or unoccupied.

Each schedule consists of from one to 8 occupied/unoccupied time periods, set by the operator. These time periods can be enabled to be in effect, or not in effect, on each day of the week and for holidays. The day begins with 0000 hours and ends with 2400 hours. The chiller is in OCCUPIED mode unless an unoccupied time period is in effect.

The chiller will shut down when the schedule goes to UN- OCCUPIED. These schedules can be set up to follow the building schedule or to be 100% OCCUPIED if the operator wishes. The schedules also can be bypassed by forcing the Start/Stop command on the PIC Status screen to start. The schedules also can be overridden to keep the unit in an OC- CUPIED mode for up to 4 hours, on a one-time basis.

Figure 18 shows a schedule for a typical office building time schedule, with a 3-hour, off-peak cool down period from midnight to 3 a.m., following a weekend shutdown. Example: Holiday periods are unoccupied 24 hours per day. The building operates Monday through Friday, 7:00 a.m. to 6:00 p.m., with a Saturday schedule of 6:00 a.m. to 1:00 p.m., and includes the Monday midnight to 3:00 a.m. weekend cool-down schedule.

NOTE: This schedule is for illustration only, and is not in- tended to be a recommended schedule for chiller operation.

PSIO Software Version 08 and Lower Ð Whenever the chiller is in the LOCAL mode, the chiller will start when the Occupancy Schedule 01 indicates OCCUPIED. When in the CCN mode, Occupancy Schedule 02 is used.

PSIO Software Version 09 and Higher Ð The Local Time Schedule is still the Occupancy Schedule 01. The Ice Build Time Schedule is Schedule 02 and the CCN Default Time Schedule is Schedule 03. The CCN schedule number is de- ®ned on the Con®g table in the Equipment Con®guration table on page 23. The schedule number can change to any value from 03 to 99. If this schedule number is changed on the Con®g table, the operator must use the Attach to Net- work Device table to upload the new number into the Sched- ule screen. See Fig. 17.