19XL specifications

The Carrier 19XL is a highly regarded commercial heating and cooling solution, designed to provide optimum performance and energy efficiency in various applications. This rooftop unit is engineered to meet the diverse needs of businesses, making it an ideal choice for those requiring reliable climate control in their facilities.One of the standout features of the Carrier 19XL is its advanced cooling and heating capabilities. The unit utilizes a high-efficiency scroll compressor that ensures a quieter operation and improved reliability. The system can operate across a wide range of temperatures, making it versatile for various climates. Additionally, it offers both cooling and heating options, allowing for year-round comfort.

Energy efficiency is a focal point of the 19XL design. With an impressive Seasonal Energy Efficiency Ratio (SEER) and Heating Seasonal Performance Factor (HSPF), this unit not only helps reduce energy costs but also supports environmental sustainability initiatives. The unit is equipped with environmentally friendly refrigerants, further contributing to lower greenhouse gas emissions.

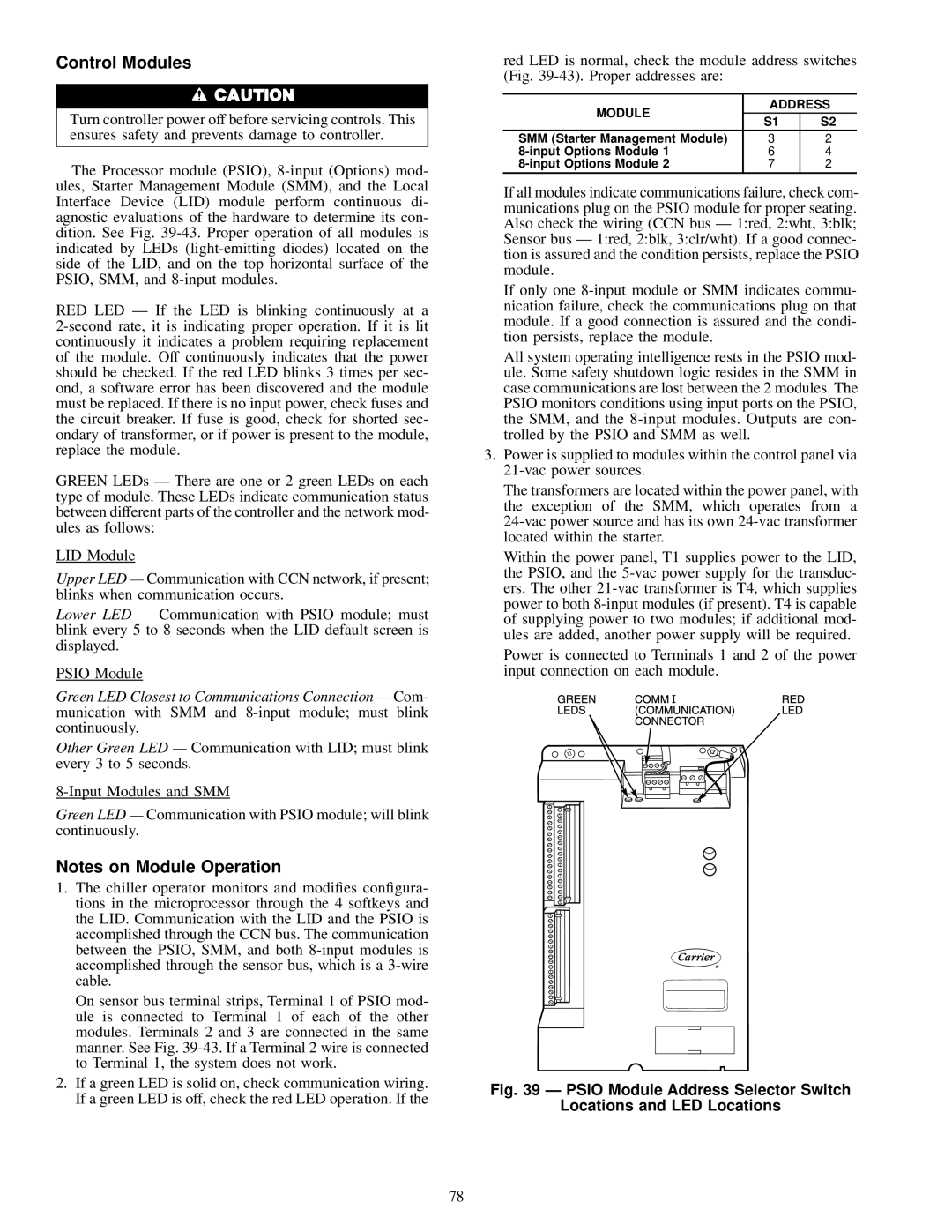

The Carrier 19XL features a user-friendly control system, allowing for easy monitoring and management of the unit's performance. This control system is designed to maximize energy savings, offering features such as demand control ventilation and integrated economizers that facilitate the use of outdoor air for cooling, reducing reliance on mechanical systems when conditions allow.

Construction-wise, the Carrier 19XL is built to withstand tough environmental conditions. Its robust cabinet is made from galvanized steel, providing durability and protection against the elements. The design also includes insulation to minimize noise levels, creating a more comfortable indoor environment.

Maintenance is a key consideration in the design of the 19XL. The unit features accessible service ports and a simplified access panel, allowing technicians to perform routine maintenance with ease. This proactive design helps ensure the longevity of the system and minimizes downtime, keeping operations running smoothly.

In summary, the Carrier 19XL is an exceptional choice for commercial heating and cooling needs. With its energy-efficient features, advanced technology, and durable construction, it stands out as a reliable solution for businesses looking for sustainable climate control options.