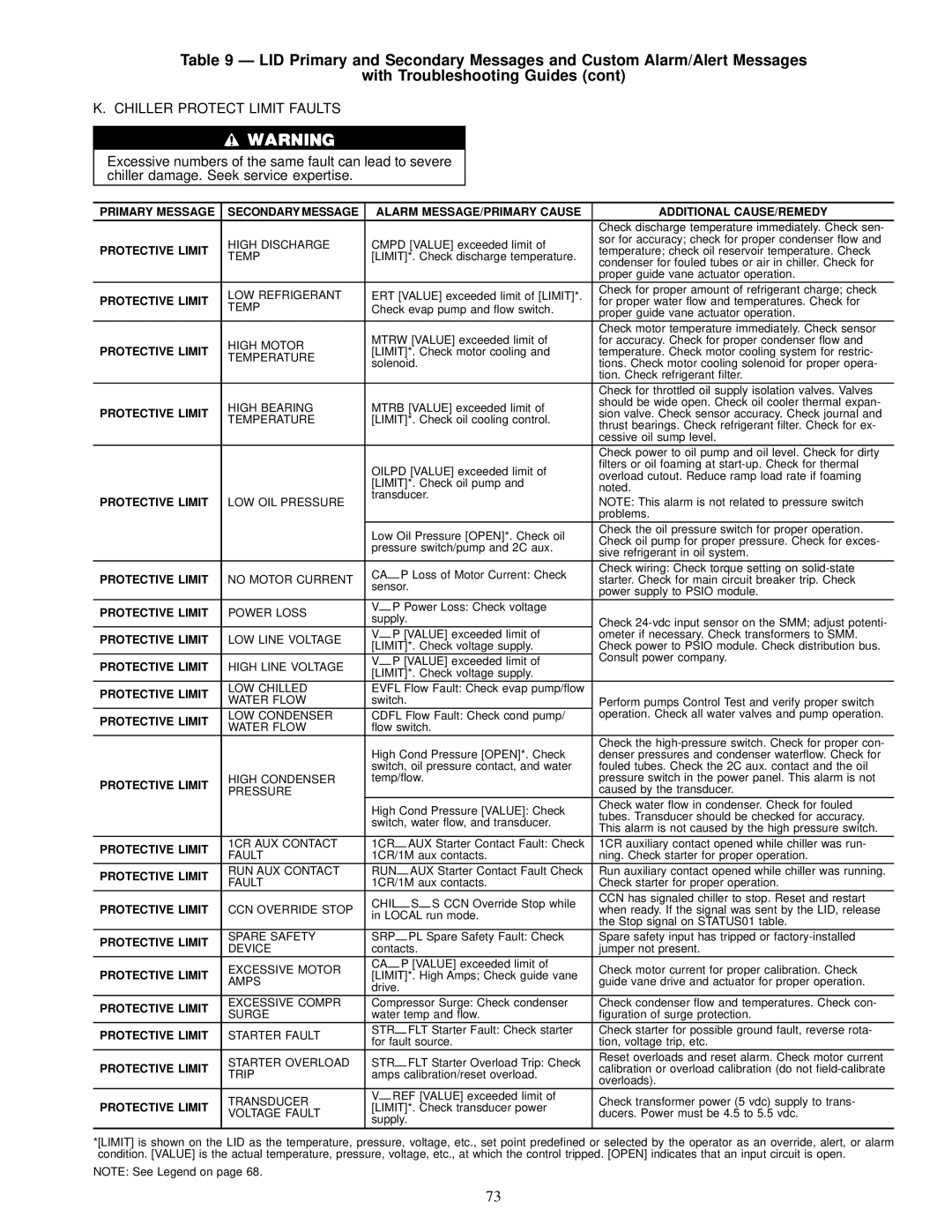

| PRIMARY MESSAGE | SECONDARY MESSAGE | ALARM MESSAGE/PRIMARY CAUSE | ADDITIONAL CAUSE/REMEDY |

| | | | | | | | | | | | | | | | | | | Check discharge temperature immediately. Check sen- |

| PROTECTIVE LIMIT | HIGH DISCHARGE | CMPD [VALUE] exceeded limit of | sor for accuracy; check for proper condenser ¯ow and |

| temperature; check oil reservoir temperature. Check |

| TEMP | [LIMIT]*. Check discharge temperature. |

| | condenser for fouled tubes or air in chiller. Check for |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | proper guide vane actuator operation. |

| PROTECTIVE LIMIT | LOW REFRIGERANT | ERT [VALUE] exceeded limit of [LIMIT]*. | Check for proper amount of refrigerant charge; check |

| for proper water ¯ow and temperatures. Check for |

| TEMP | Check evap pump and ¯ow switch. |

| | proper guide vane actuator operation. |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | Check motor temperature immediately. Check sensor |

| PROTECTIVE LIMIT | HIGH MOTOR | MTRW [VALUE] exceeded limit of | for accuracy. Check for proper condenser ¯ow and |

| [LIMIT]*. Check motor cooling and | temperature. Check motor cooling system for restric- |

| TEMPERATURE |

| | solenoid. | tions. Check motor cooling solenoid for proper opera- |

| | |

| | | | | | | | | | | | | | | | | | | tion. Check refrigerant ®lter. |

| | | | | | | | | | | | | | | | | | | Check for throttled oil supply isolation valves. Valves |

| PROTECTIVE LIMIT | HIGH BEARING | MTRB [VALUE] exceeded limit of | should be wide open. Check oil cooler thermal expan- |

| sion valve. Check sensor accuracy. Check journal and |

| TEMPERATURE | [LIMIT]*. Check oil cooling control. |

| | thrust bearings. Check refrigerant ®lter. Check for ex- |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | cessive oil sump level. |

| | | | | | | | | | | | | | | | | | | Check power to oil pump and oil level. Check for dirty |

| | | OILPD [VALUE] exceeded limit of | ®lters or oil foaming at start-up. Check for thermal |

| | | overload cutout. Reduce ramp load rate if foaming |

| | | [LIMIT]*. Check oil pump and |

| | | noted. |

| | | transducer. |

| PROTECTIVE LIMIT | LOW OIL PRESSURE | NOTE: This alarm is not related to pressure switch |

| | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | problems. |

| | | Low Oil Pressure [OPEN]*. Check oil | Check the oil pressure switch for proper operation. |

| | | Check oil pump for proper pressure. Check for exces- |

| | | pressure switch/pump and 2C aux. |

| | | sive refrigerant in oil system. |

| | | | | | | | | | | | | | | | | | |

| PROTECTIVE LIMIT | NO MOTOR CURRENT | CA | | | | | | | | P Loss of Motor Current: Check | Check wiring: Check torque setting on solid-state |

| | | | | | | | starter. Check for main circuit breaker trip. Check |

| sensor. |

| | | power supply to PSIO module. |

| | | | | | | | | | | | | | | | | | |

| PROTECTIVE LIMIT | POWER LOSS | V | | P Power Loss: Check voltage | |

| supply. | Check 24-vdc input sensor on the SMM; adjust potenti- |

| | |

| PROTECTIVE LIMIT | LOW LINE VOLTAGE | V | | P [VALUE] exceeded limit of | ometer if necessary. Check transformers to SMM. |

| [LIMIT]*. Check voltage supply. | Check power to PSIO module. Check distribution bus. |

| | |

| | | | | | | | | | | | | | | | | | | Consult power company. |

| PROTECTIVE LIMIT | HIGH LINE VOLTAGE | V | | | P [VALUE] exceeded limit of |

| [LIMIT]*. Check voltage supply. | |

| | | |

| PROTECTIVE LIMIT | LOW CHILLED | EVFL Flow Fault: Check evap pump/¯ow | |

| WATER FLOW | switch. | Perform pumps Control Test and verify proper switch |

| |

| PROTECTIVE LIMIT | LOW CONDENSER | CDFL Flow Fault: Check cond pump/ | operation. Check all water valves and pump operation. |

| WATER FLOW | ¯ow switch. | |

| | |

| | | | | | | | | | | | | | | | | | | Check the high-pressure switch. Check for proper con- |

| | | High Cond Pressure [OPEN]*. Check | denser pressures and condenser water¯ow. Check for |

| | | switch, oil pressure contact, and water | fouled tubes. Check the 2C aux. contact and the oil |

| PROTECTIVE LIMIT | HIGH CONDENSER | temp/¯ow. | pressure switch in the power panel. This alarm is not |

| PRESSURE | | | | | | | | | | | | | | | | | caused by the transducer. |

| | | | | | | | | | | | | | | | | |

| | | High Cond Pressure [VALUE]: Check | Check water ¯ow in condenser. Check for fouled |

| | | tubes. Transducer should be checked for accuracy. |

| | | switch, water ¯ow, and transducer. |

| | | This alarm is not caused by the high pressure switch. |

| | | | | | | | | | | | | | | | | | |

| PROTECTIVE LIMIT | 1CR AUX CONTACT | 1CR | | | | | | | | AUX Starter Contact Fault: Check | 1CR auxiliary contact opened while chiller was run- |

| FAULT | 1CR/1M aux contacts. | ning. Check starter for proper operation. |

| |

| PROTECTIVE LIMIT | RUN AUX CONTACT | RUN | | | | | | | AUX Starter Contact Fault Check | Run auxiliary contact opened while chiller was running. |

| FAULT | 1CR/1M aux contacts. | Check starter for proper operation. |

| |

| PROTECTIVE LIMIT | CCN OVERRIDE STOP | CHIL | | | | | | S | | S CCN Override Stop while | CCN has signaled chiller to stop. Reset and restart |

| | | | | | | when ready. If the signal was sent by the LID, release |

| in LOCAL run mode. |

| | | the Stop signal on STATUS01 table. |

| | | | | | | | | | | | | | | | | | |

| PROTECTIVE LIMIT | SPARE SAFETY | SRP | | | | | PL Spare Safety Fault: Check | Spare safety input has tripped or factory-installed |

| DEVICE | contacts. | jumper not present. |

| |

| PROTECTIVE LIMIT | EXCESSIVE MOTOR | CA | | | P [VALUE] exceeded limit of | Check motor current for proper calibration. Check |

| [LIMIT]*. High Amps; Check guide vane |

| AMPS | guide vane drive and actuator for proper operation. |

| | drive. | | | | | | | |

| | | | | | | | | | |

| PROTECTIVE LIMIT | EXCESSIVE COMPR | Compressor Surge: Check condenser | Check condenser ¯ow and temperatures. Check con- |

| SURGE | water temp and ¯ow. | ®guration of surge protection. |

| |

| PROTECTIVE LIMIT | STARTER FAULT | STR | | | | FLT Starter Fault: Check starter | Check starter for possible ground fault, reverse rota- |

| for fault source. | tion, voltage trip, etc. |

| | |

| PROTECTIVE LIMIT | STARTER OVERLOAD | STR | | | | | | | FLT Starter Overload Trip: Check | Reset overloads and reset alarm. Check motor current |

| | | | calibration or overload calibration (do not ®eld-calibrate |

| TRIP | amps calibration/reset overload. |

| | overloads). |

| | | | | | | | | | | | | | | | | | |

| PROTECTIVE LIMIT | TRANSDUCER | V | | REF [VALUE] exceeded limit of | Check transformer power (5 vdc) supply to trans- |

| [LIMIT]*. Check transducer power |

| VOLTAGE FAULT | ducers. Power must be 4.5 to 5.5 vdc. |

| | supply. |

| | | |

| | | | | | | | | | | | | | | | | | | |