Safety Considerations

Start-Up, Operation, and Maintenance Instructions

Contents

Contents

Abbreviations and Explanations

Introduction

MOTOR/OIL Refrigeration Cooling Cycle

Chiller Familiarization

Refrigeration Cycle

19XL Rear View

Cooler Pressure Schrader Fitting

Take-Apart Rabbet Fit Connector

Cooler In/Out Temperature Sensors

Condenser In/Out Temperature Sensors

Refrigerant Motor Cooling and Oil Cooling Cycles

Lubrication Cycle

Lubrication System

Unit-Mounted Solid-State Starter Optional

Starting Equipment

PIC Component Panel

Denitions

Controls

Major PIC Components Panel Locations

Pressure Transducer, Typical

19XL Controls and Sensor Locations

Control and OIL Heater Voltage Selector S1

Power Panel with Options

Select

LID Operation and Menus Fig

General

Override Operations

− Example of Point Status Screen Status01

Example of Time Schedule Operation Screen

19XL Menu Structure

19XL Service Menu Structure

19XL Service Menu Structure

Example of Set Point Screen

Setpoint

Menu Status Select

Description Range Units Reference Point Name Alarm History

LID Screens

Example 1 Ð STATUS01 Display Screen

Menu

Example 2 Ð STATUS02 Display Screen

Example 3 Ð STATUS03 Display Screen

Example 4 Ð Setpoint Display Screen

ICE Build Termination

Example 5 Ð Configuration Config Display Screen

Example 6 Ð LEAD/LAG Configuration Display Screen

ECW Control Option

Example 7 Ð SERVICE1 Display Screen

Menu Service

Example 8 Ð SERVICE2 Display Screen

Spare Alert Enable

Example 9 Ð SERVICE3 Display Screen

Bearing Temperature

Example 10 Ð Maintenance MAINT01 Display Screen

Example 11 Ð Maintenance MAINT02 Display Screen

Discharge Temperature

Description RANGE/STATUS Units Reference Point Name

Example 12 Ð Maintenance MAINT03 Display Screen

Example 13 Ð Maintenance MAINT04 Display Screen

PIC System Functions

Page

Protective Safety Limits and Control Settings

Capacity Overrides

Page

Page

Hot Gas Bypass

Lead/Lag Control

ECW

Hgbp

Page

Cent Capacity

Ice Build Control

Page

To LOG on

Example of Attach to Network Device Screen

Sequence Fig

START-UP/SHUTDOWN/RECYCLE

Recycle Restart Delta T

Equipment Required

Using the Optional Storage Tank and Pumpout

Before Initial START-UP

Job Data Required

19XL Leak Test Procedures

Page

Ð HCFC-22 Pressure Ð Temperature C

Ð HCFC-22 Pressure Ð Temperature F

Temperature Pressure

Ð HFC-134a Pressure Ð Temperature F

Ð HFC-134a Pressure Ð Temperature C

Page

Check Optional Pumpout Compressor Water Pip

Inspect Wiring

MECHANICAL-TYPE Starters

Check Starter

BENSHAW, INC. SOLID-STATE Starter

Benshaw, Inc. Solid-State Starter Power Stack

Set Up Chiller Control Conguration

Power Up the Controls and Check the Oil Heater

Load Surge Prevention Occurs TOO Soon Occurs TOO Late

Volt Motor Code

Amps Correction Factors For 19XL Motors

Tests to be Devices Tested Performed

Charge Refrigerant into Chiller

19XL Chiller Equalization Without PUMP- OUT Unit

Control Test Menu Functions

Size

Refrigerant Charges

19XL Total Refrigerant Charge

Cooler

Check Rotation

Initial START-UP

Dry Run to Test Start-Up Sequence

Operator Duties

Check Oil Pressure and Compressor Stop

Calibrate Motor Current

Operating Instructions

To Stop the Chiller

Plant

Tstat

Pumpout and Refrigerant Transfer Procedures

Operating the Optional Pumpout Compressor

Transfer Refrigerant from Storage Tank to Chiller

Transfer the Refrigerant from Chiller to Storage Tank

Chillers with Isolation Valves

Return Refrigerant to Normal Operating Conditions

General Maintenance

Test After Service, Repair, or Major Leak Ð If

Guide Vane Actuator Linkage

Weekly Maintenance

To Change the OIL

Scheduled Maintenance

Check Safety and Operating Controls Monthly

Inspect the Heat Exchanger Tubes

Compressor Bearing and Gear Mainten

Optional Pumpout System Controls

Troubleshooting Guide

MAINT04

MAINT01

MAINT02

MAINT03

Timing OUT or Timed OUT

Shutdown with ON/OFF/RESET-OFF

Autorestart in Progress

Recycle Shutdown

Normal or AUTO.-RESTART

LOW Chilled Water

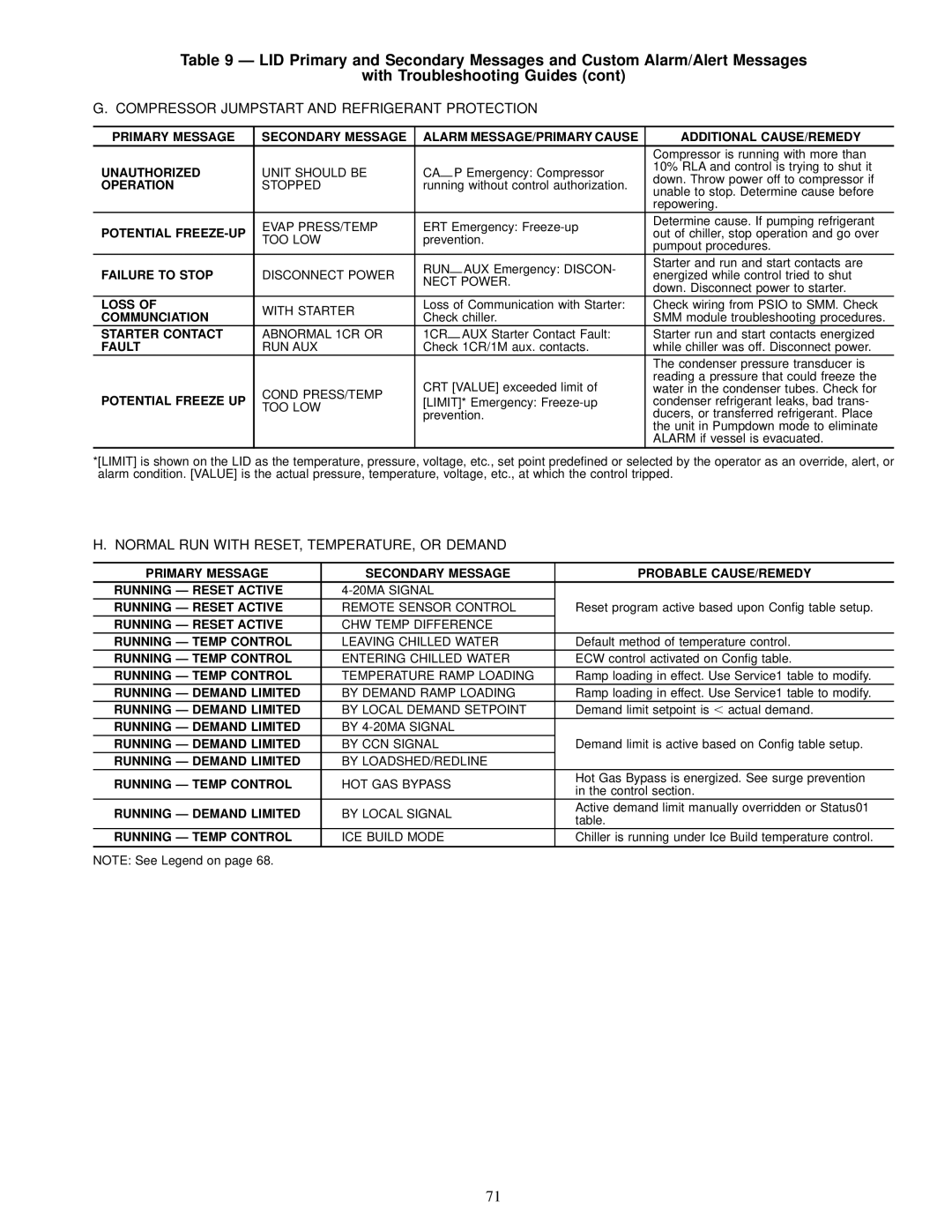

Compressor Jumpstart and Refrigerant Protection

Normal RUN with RESET, TEMPERATURE, or Demand

Limited

Normal RUN Overrides Active Alerts

OUT-OF-RANGE Sensor Failures

Protective Limit

Chiller Protect Limit Faults

Spare Sensor Alert Messages

Chiller Alerts

DESCRIPTION/MALFUNCTION Probable CAUSE/REMEDY

Other PROBLEMS/MALFUNCTIONS

Temperature Voltage Resistance Drop

Ð Thermistor Temperature F vs Resistance/Voltage Drop

Ð Thermistor Temperature C vs Resistance/Voltage Drop

Input Options Module

Control Modules

Module Address

Options Module

Starter Management Module SMM Fig

Processor Module Psio Fig

Switch Options Setting Module

Installation

Typical Benshaw, Inc. Solid-State Starter internal View

Page

Page

SCR

Benshaw, Inc. Solid-State Starter Troubleshooting Guide

Problem Probable Causes Area of Correction

RV1

Condenser

Heat Exchanger Data

Additional Data for Marine Waterboxes

Cooler

1034 kPa

Waterbox Cover Weights

Coolers

Condensers

Optional Pumpout System Electrical Data

Compressor/Motor Weights

Compressor Weights

Compressor Fits and Clearances

``Z

Compressor Assembly Torques

Description Torque

Ft-lb

EXT

CLR

COM

Comm

Page

CLR

Page

Chiller Power Panel, Starter Assembly Motor Wiring Schematic

Chiller Power Panel, Starter Assembly Motor Wiring Schematic

HPS

PMR

POT

GFR

Typical Wye-Delta Unit Mounted Starter Wiring Schematic

Index

Index

Copyright 1996 Carrier Corporation