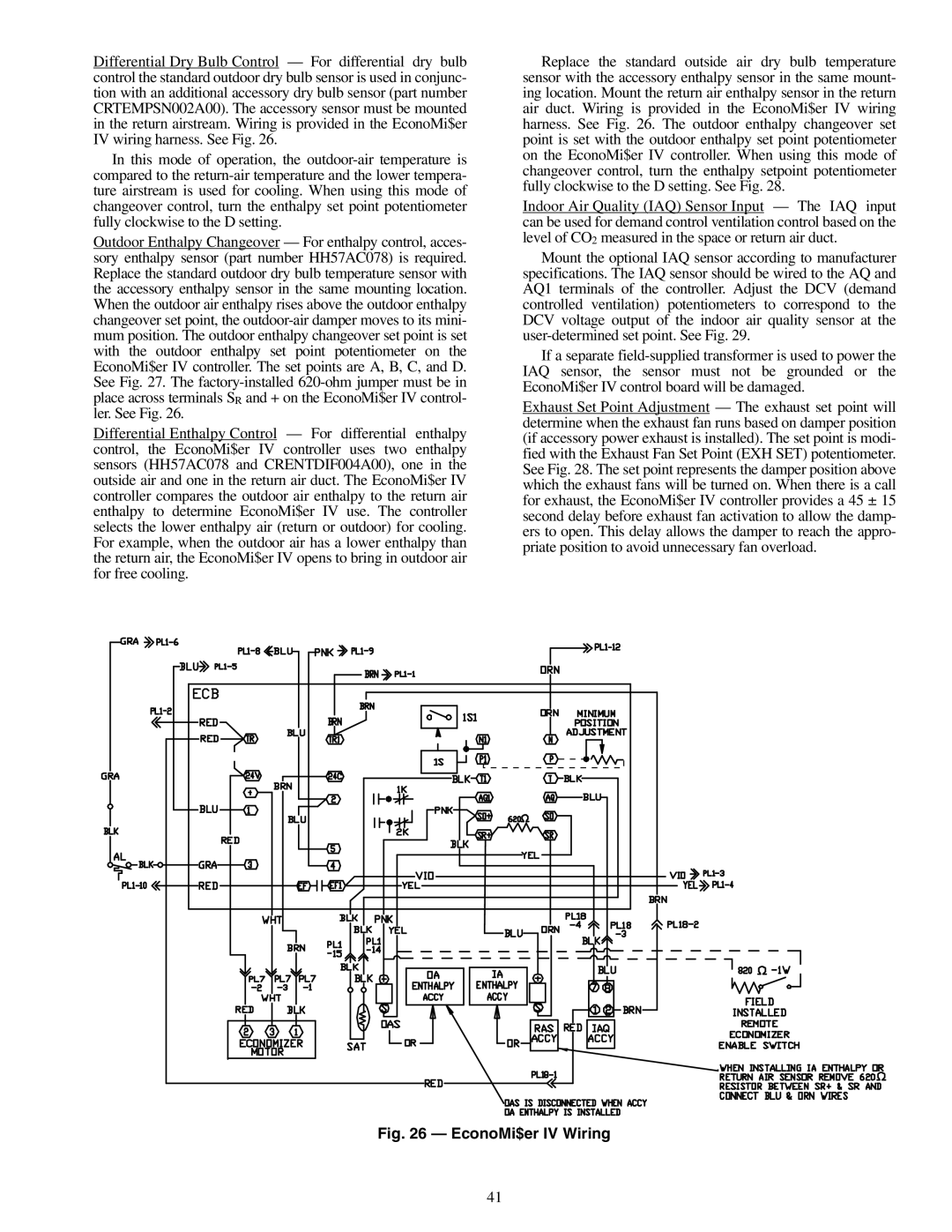

Differential Dry Bulb Control — For differential dry bulb control the standard outdoor dry bulb sensor is used in conjunc- tion with an additional accessory dry bulb sensor (part number CRTEMPSN002A00). The accessory sensor must be mounted in the return airstream. Wiring is provided in the EconoMi$er IV wiring harness. See Fig. 26.

In this mode of operation, the

Outdoor Enthalpy Changeover — For enthalpy control, acces- sory enthalpy sensor (part number HH57AC078) is required. Replace the standard outdoor dry bulb temperature sensor with the accessory enthalpy sensor in the same mounting location. When the outdoor air enthalpy rises above the outdoor enthalpy changeover set point, the

Differential Enthalpy Control — For differential enthalpy control, the EconoMi$er IV controller uses two enthalpy sensors (HH57AC078 and CRENTDIF004A00), one in the outside air and one in the return air duct. The EconoMi$er IV controller compares the outdoor air enthalpy to the return air enthalpy to determine EconoMi$er IV use. The controller selects the lower enthalpy air (return or outdoor) for cooling. For example, when the outdoor air has a lower enthalpy than the return air, the EconoMi$er IV opens to bring in outdoor air for free cooling.

Replace the standard outside air dry bulb temperature sensor with the accessory enthalpy sensor in the same mount- ing location. Mount the return air enthalpy sensor in the return air duct. Wiring is provided in the EconoMi$er IV wiring harness. See Fig. 26. The outdoor enthalpy changeover set point is set with the outdoor enthalpy set point potentiometer on the EconoMi$er IV controller. When using this mode of changeover control, turn the enthalpy setpoint potentiometer fully clockwise to the D setting. See Fig. 28.

Indoor Air Quality (IAQ) Sensor Input — The IAQ input can be used for demand control ventilation control based on the level of CO2 measured in the space or return air duct.

Mount the optional IAQ sensor according to manufacturer specifications. The IAQ sensor should be wired to the AQ and AQ1 terminals of the controller. Adjust the DCV (demand controlled ventilation) potentiometers to correspond to the DCV voltage output of the indoor air quality sensor at the

If a separate

Exhaust Set Point Adjustment — The exhaust set point will determine when the exhaust fan runs based on damper position (if accessory power exhaust is installed). The set point is modi- fied with the Exhaust Fan Set Point (EXH SET) potentiometer. See Fig. 28. The set point represents the damper position above which the exhaust fans will be turned on. When there is a call for exhaust, the EconoMi$er IV controller provides a 45 ± 15 second delay before exhaust fan activation to allow the damp- ers to open. This delay allows the damper to reach the appro- priate position to avoid unnecessary fan overload.

Fig. 26 — EconoMi$er IV Wiring

41