Table 30 — Belt Tension Adjustment

|

|

|

|

| BELT TENSION (lb) |

|

|

| ||

48PG | VOLTAGE |

|

|

| Unit Model Number Position 10 |

|

|

| ||

|

| A,J | B,K | C,L | D,M | E,N |

| F,P | G,Q | H,R |

| 230 | 4.8 | 5.1 | 5.6 | 4.5 | NA |

| 4.7 | 5.0 | 5.5 |

20 | 460 | 4.8 | 5.1 | 5.6 | 4.5 | NA |

| 4.7 | 5.0 | 5.5 |

| 575 | 5.3 | 5.1 | 5.6 | 4.5 | NA |

| 5.2 | 5.0 | 5.5 |

| 230 | 4.8 | 5.1 | 5.6 | 4.5 | NA |

| 4.7 | 5.0 | 5.5 |

24 | 460 | 4.8 | 5.1 | 5.6 | 4.5 | NA |

| 4.7 | 5.0 | 5.5 |

| 575 | 5.3 | 5.1 | 5.6 | 4.5 | NA |

| 5.2 | 5.0 | 5.5 |

| 230 | 4.5 | 5.4 | 5.9 | 4.5 | 4.5 |

| 5.4 | 5.9 | 4.5 |

28 | 460 | 4.5 | 5.4 | 5.9 | 4.5 | 4.5 |

| 5.4 | 5.9 | 4.5 |

| 575 | 4.5 | 5.4 | 5.9 | 4.5 | 4.5 |

| 5.4 | 5.9 | 4.5 |

Condenser-Fan Adjustment (Fig. 35)

1.Shut off unit power supply.

2.Remove

3.Adjust fan height as shown in Fig. 35.

4.Tighten setscrews and replace

5.Turn on power to unit.

Fig. 35 — Condenser-Fan Adjustment

Verify Sensor Performance — Using an ohmmeter and a thermometer, compare measured temperature to the resistance shown in Table 31.

Table 31 — Sensor Temperature/Resistance Values

TEMPERATURE (F) | RESISTANCE (ohms) |

200,250 | |

100,680 | |

53,010 | |

29,091 | |

14 | 16,590 |

32 | 9,795 |

50 | 5,970 |

68 | 3,747 |

77 | 3,000 |

86 | 2,416 |

104 | 1,597 |

122 | 1,080 |

140 | 746 |

158 | 525 |

176 | 376 |

185 | 321 |

194 | 274 |

212 | 203 |

230 | 153 |

248 | 116 |

257 | 102 |

266 | 89 |

284 | 70 |

302 | 55 |

Economizer Operation During Power Fail- ure — Dampers have a spring return. In event of power fail- ure, dampers will return to fully closed position until power is restored. Do not manually operate damper motor.

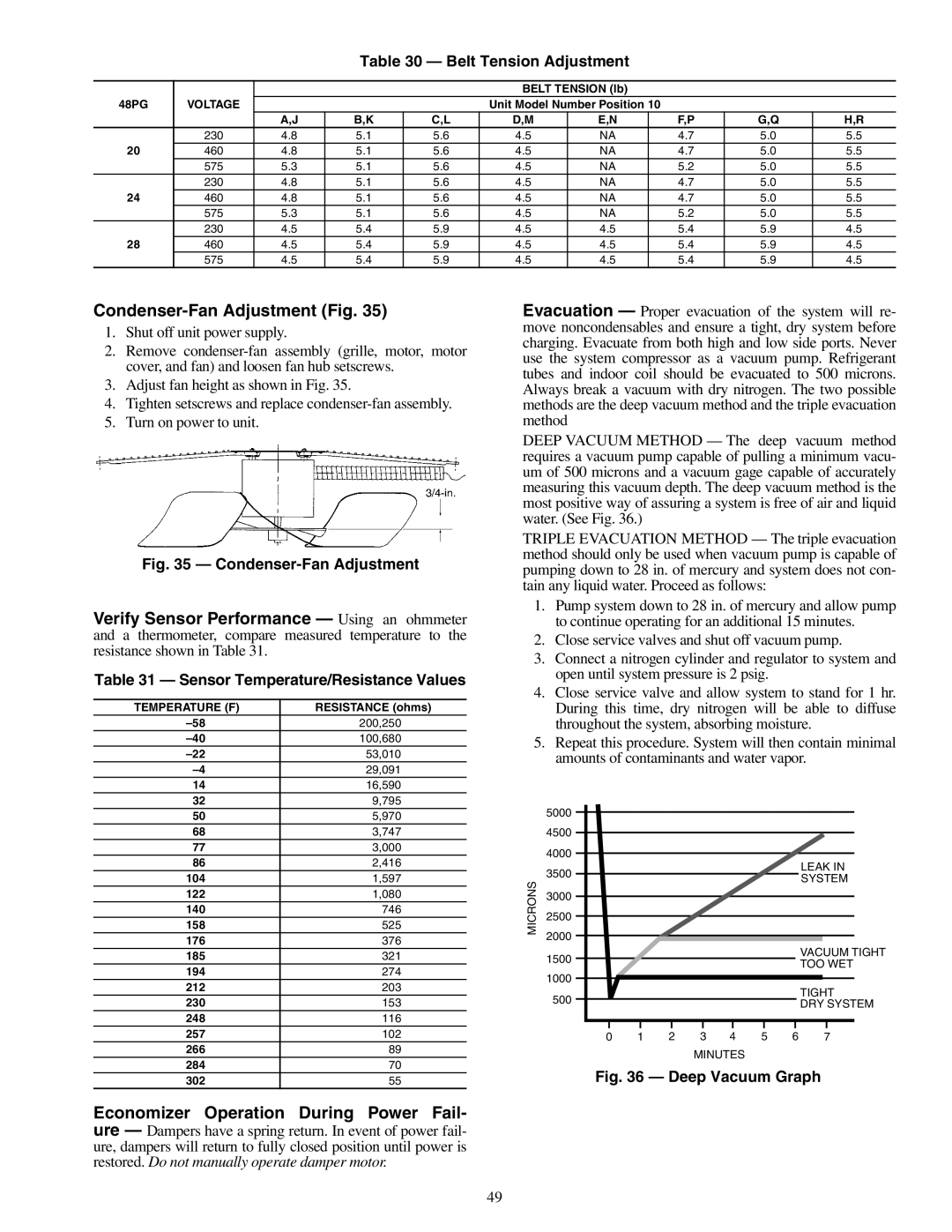

Evacuation — Proper evacuation of the system will re- move noncondensables and ensure a tight, dry system before charging. Evacuate from both high and low side ports. Never use the system compressor as a vacuum pump. Refrigerant tubes and indoor coil should be evacuated to 500 microns. Always break a vacuum with dry nitrogen. The two possible methods are the deep vacuum method and the triple evacuation method

DEEP VACUUM METHOD — The deep vacuum method requires a vacuum pump capable of pulling a minimum vacu- um of 500 microns and a vacuum gage capable of accurately measuring this vacuum depth. The deep vacuum method is the most positive way of assuring a system is free of air and liquid water. (See Fig. 36.)

TRIPLE EVACUATION METHOD — The triple evacuation method should only be used when vacuum pump is capable of pumping down to 28 in. of mercury and system does not con- tain any liquid water. Proceed as follows:

1.Pump system down to 28 in. of mercury and allow pump to continue operating for an additional 15 minutes.

2.Close service valves and shut off vacuum pump.

3.Connect a nitrogen cylinder and regulator to system and open until system pressure is 2 psig.

4.Close service valve and allow system to stand for 1 hr. During this time, dry nitrogen will be able to diffuse throughout the system, absorbing moisture.

5.Repeat this procedure. System will then contain minimal amounts of contaminants and water vapor.

| 5000 |

|

|

|

|

|

|

|

| 4500 |

|

|

|

|

|

|

|

| 4000 |

|

|

|

|

|

|

|

| 3500 |

|

|

|

|

|

| LEAK IN |

MICRONS |

|

|

|

|

|

| SYSTEM | |

|

|

|

|

|

|

| ||

3000 |

|

|

|

|

|

|

| |

2500 |

|

|

|

|

|

|

| |

2000 |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

| 1500 |

|

|

|

|

|

| VACUUM TIGHT |

|

|

|

|

|

|

| TOO WET | |

|

|

|

|

|

|

|

| |

| 1000 |

|

|

|

|

|

|

|

| 500 |

|

|

|

|

|

| TIGHT |

|

|

|

|

|

|

| DRY SYSTEM | |

|

|

|

|

|

|

|

| |

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|

|

|

| MINUTES |

|

|

| |

Fig. 36 — Deep Vacuum Graph

49