FAN SHAFT BEARINGS — Lubricate bearings at least ev- ery 6 months with suitable bearing grease. Typical lubricants are given below:

MANUFACTURER | LUBRICANT |

Texaco | Regal |

Mobil | Mobilplex EP No. 1 |

Sunoco | Prestige 42 |

Texaco | Multifak 2 |

*Preferred lubricant because it contains rust and oxidation inhibitors.

FAN MOTOR BEARINGS — Fan motor bearings are of the permanently lubricated type. No field lubrication is required. No lubrication of the condenser or evaporator motors are required.

Manual Outdoor Air Damper — If manual outdoor air damper blade adjustment is required, refer to Step 10 — In- stall Outdoor Air Hood section on page 12.

Economizer Adjustment — If economizer adjustment is required, refer to Optional EconoMi$er IV section on page 39.

Evaporator Fan Service and Replacement — The 48PG units feature a

1.Turn off unit power.

2.Open the fan section access panel.

3.Remove three no. 10 screws at front of

4.Disconnect the limit switch wires located on the right side of the fan deck. Other wires do not need to be disconnected.

5.Fan deck can now be slid out to access serviceable components.

DO NOT SLIDE FAN DECK OUT PAST THE STOP BRACKET. If further access is required, the fan deck must be supported. Make sure plugs and wiring are not pinched between fan housing and unit center post. Damage to unit may result.

6.To replace fan deck to operating position, slide fan deck back into the unit. Secure with the three no. 10 screws removed in Step 3.

7.

8.Close fan section access door.

9.Restore power to unit.

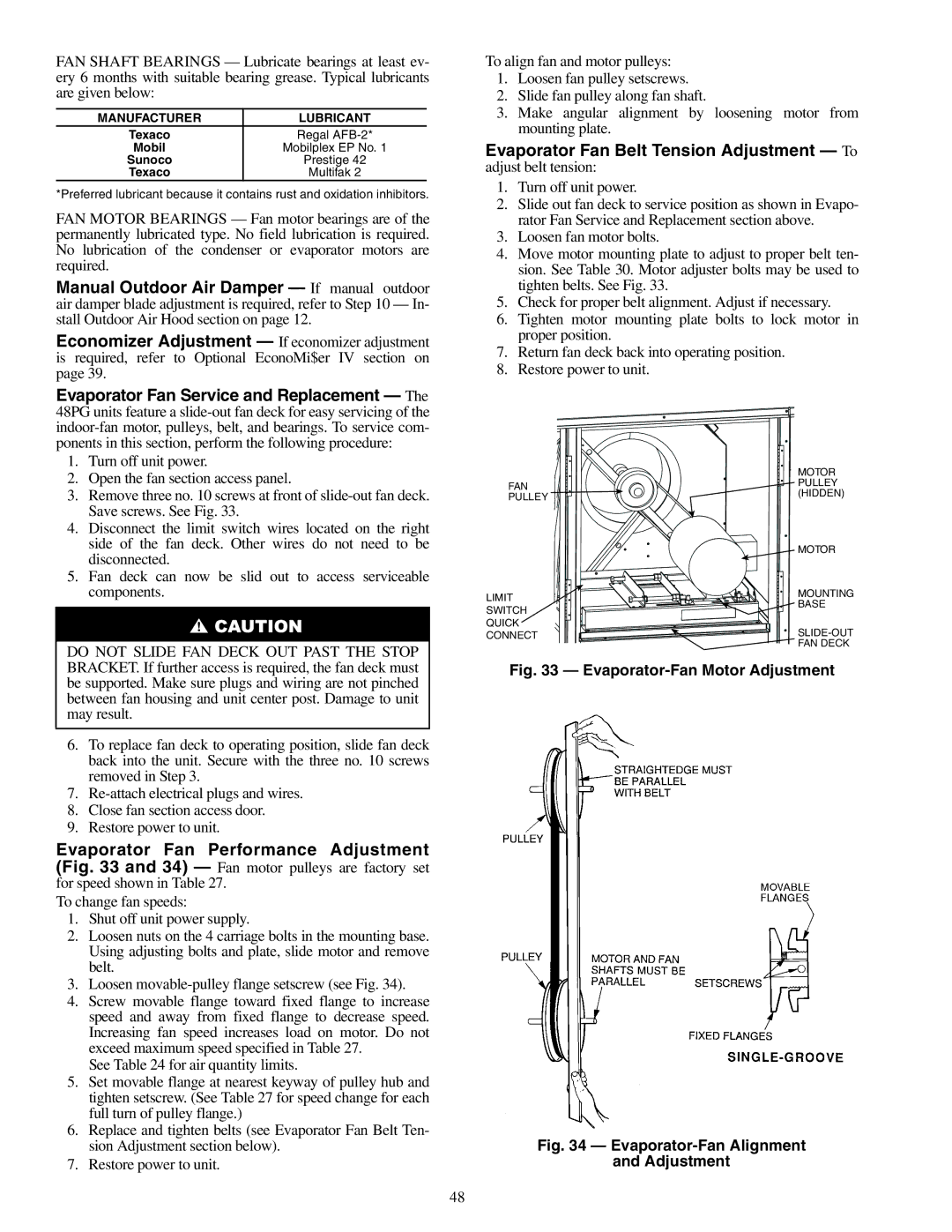

Evaporator Fan Performance Adjustment (Fig. 33 and 34) — Fan motor pulleys are factory set for speed shown in Table 27.

To change fan speeds:

1.Shut off unit power supply.

2.Loosen nuts on the 4 carriage bolts in the mounting base. Using adjusting bolts and plate, slide motor and remove belt.

3.Loosen

4.Screw movable flange toward fixed flange to increase speed and away from fixed flange to decrease speed. Increasing fan speed increases load on motor. Do not exceed maximum speed specified in Table 27.

See Table 24 for air quantity limits.

5.Set movable flange at nearest keyway of pulley hub and tighten setscrew. (See Table 27 for speed change for each full turn of pulley flange.)

6.Replace and tighten belts (see Evaporator Fan Belt Ten- sion Adjustment section below).

7.Restore power to unit.

To align fan and motor pulleys:

1.Loosen fan pulley setscrews.

2.Slide fan pulley along fan shaft.

3.Make angular alignment by loosening motor from mounting plate.

Evaporator Fan Belt Tension Adjustment — To adjust belt tension:

1.Turn off unit power.

2.Slide out fan deck to service position as shown in Evapo- rator Fan Service and Replacement section above.

3.Loosen fan motor bolts.

4.Move motor mounting plate to adjust to proper belt ten- sion. See Table 30. Motor adjuster bolts may be used to tighten belts. See Fig. 33.

5.Check for proper belt alignment. Adjust if necessary.

6.Tighten motor mounting plate bolts to lock motor in proper position.

7.Return fan deck back into operating position.

8.Restore power to unit.

| MOTOR | |

FAN | PULLEY | |

(HIDDEN) | ||

PULLEY | ||

| ||

| MOTOR | |

LIMIT | MOUNTING | |

BASE | ||

SWITCH | ||

| ||

QUICK | ||

CONNECT | ||

| FAN DECK |

Fig. 33 — Evaporator-Fan Motor Adjustment

Fig. 34 — Evaporator-Fan Alignment

and Adjustment

48