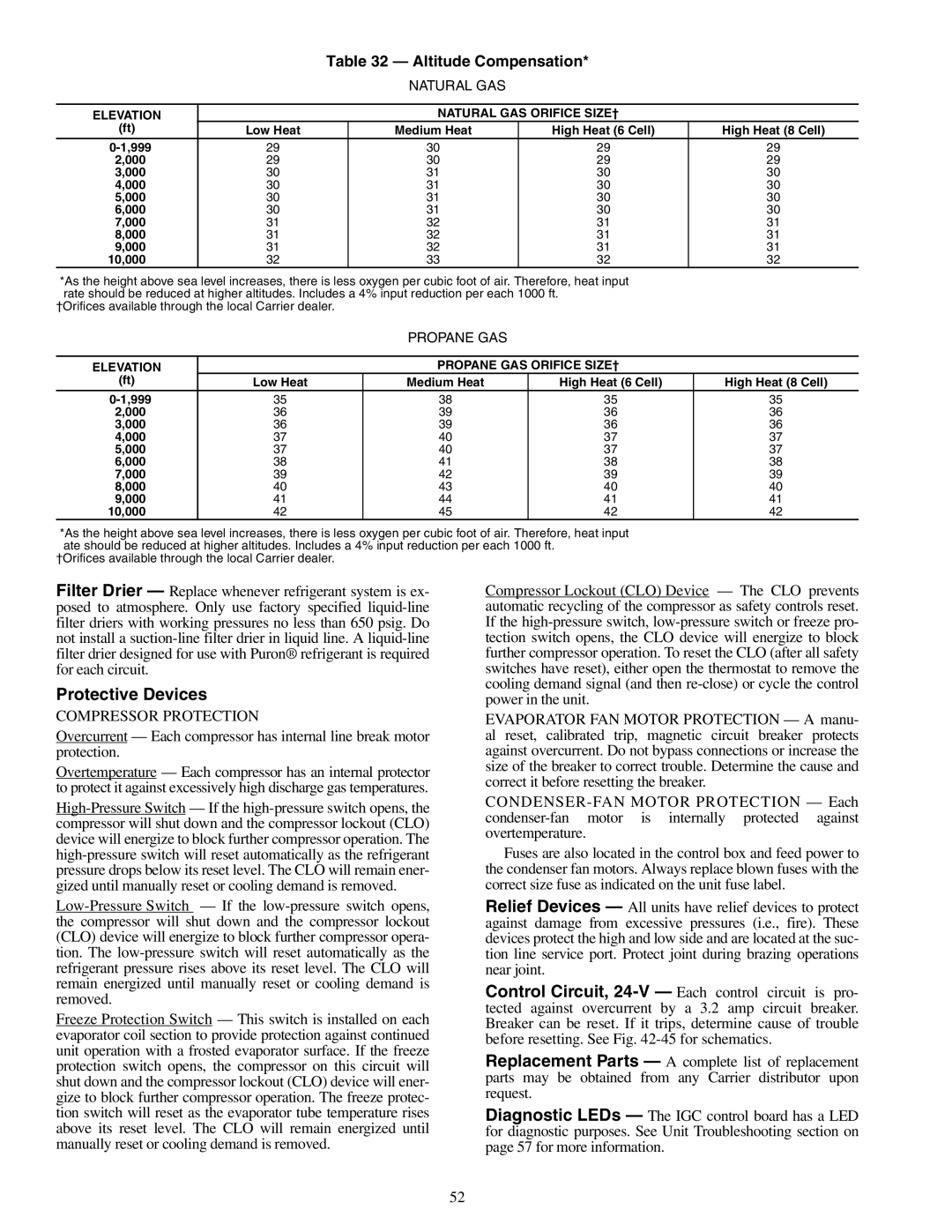

Table 32 — Altitude Compensation*

NATURAL GAS

ELEVATION |

| NATURAL GAS ORIFICE SIZE† |

| ||

(ft) |

| Low Heat | Medium Heat | High Heat (6 Cell) | High Heat (8 Cell) |

|

| 29 | 30 | 29 | 29 |

2,000 |

| 29 | 30 | 29 | 29 |

3,000 |

| 30 | 31 | 30 | 30 |

4,000 |

| 30 | 31 | 30 | 30 |

5,000 |

| 30 | 31 | 30 | 30 |

6,000 |

| 30 | 31 | 30 | 30 |

7,000 |

| 31 | 32 | 31 | 31 |

8,000 |

| 31 | 32 | 31 | 31 |

9,000 |

| 31 | 32 | 31 | 31 |

10,000 |

| 32 | 33 | 32 | 32 |

*As the height above sea level increases, there is less oxygen per cubic foot of air. Therefore, heat input |

| ||||

rate should be reduced at higher altitudes. Includes a 4% input reduction per each 1000 ft. |

| ||||

†Orifices available through the local Carrier dealer. |

|

|

| ||

PROPANE GAS

ELEVATION |

| PROPANE GAS ORIFICE SIZE† |

| |

(ft) | Low Heat | Medium Heat | High Heat (6 Cell) | High Heat (8 Cell) |

35 | 38 | 35 | 35 | |

2,000 | 36 | 39 | 36 | 36 |

3,000 | 36 | 39 | 36 | 36 |

4,000 | 37 | 40 | 37 | 37 |

5,000 | 37 | 40 | 37 | 37 |

6,000 | 38 | 41 | 38 | 38 |

7,000 | 39 | 42 | 39 | 39 |

8,000 | 40 | 43 | 40 | 40 |

9,000 | 41 | 44 | 41 | 41 |

10,000 | 42 | 45 | 42 | 42 |

*As the height above sea level increases, there is less oxygen per cubic foot of air. Therefore, heat input ate should be reduced at higher altitudes. Includes a 4% input reduction per each 1000 ft.

†Orifices available through the local Carrier dealer.

Filter Drier — Replace whenever refrigerant system is ex- posed to atmosphere. Only use factory specified

Protective Devices

COMPRESSOR PROTECTION

Overcurrent — Each compressor has internal line break motor protection.

Overtemperature — Each compressor has an internal protector to protect it against excessively high discharge gas temperatures.

Freeze Protection Switch — This switch is installed on each evaporator coil section to provide protection against continued unit operation with a frosted evaporator surface. If the freeze protection switch opens, the compressor on this circuit will shut down and the compressor lockout (CLO) device will ener- gize to block further compressor operation. The freeze protec- tion switch will reset as the evaporator tube temperature rises above its reset level. The CLO will remain energized until manually reset or cooling demand is removed.

Compressor Lockout (CLO) Device — The CLO prevents automatic recycling of the compressor as safety controls reset. If the

EVAPORATOR FAN MOTOR PROTECTION — A manu- al reset, calibrated trip, magnetic circuit breaker protects against overcurrent. Do not bypass connections or increase the size of the breaker to correct trouble. Determine the cause and correct it before resetting the breaker.

Fuses are also located in the control box and feed power to the condenser fan motors. Always replace blown fuses with the correct size fuse as indicated on the unit fuse label.

Relief Devices — All units have relief devices to protect against damage from excessive pressures (i.e., fire). These devices protect the high and low side and are located at the suc- tion line service port. Protect joint during brazing operations near joint.

Control Circuit,

Replacement Parts — A complete list of replacement parts may be obtained from any Carrier distributor upon request.

Diagnostic LEDs — The IGC control board has a LED for diagnostic purposes. See Unit Troubleshooting section on page 57 for more information.

52