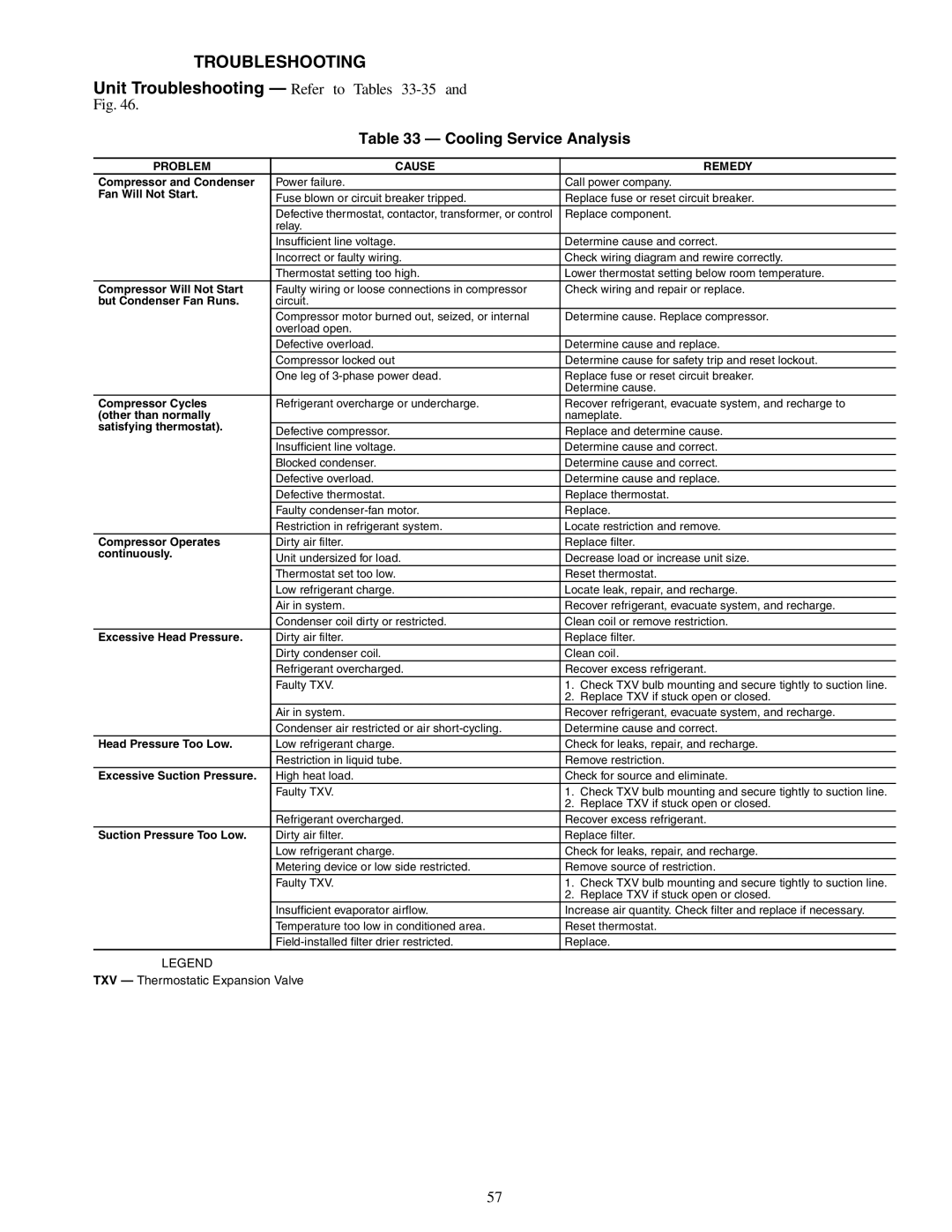

TROUBLESHOOTING

Unit Troubleshooting — Refer to Tables

Fig. 46.

Table 33 — Cooling Service Analysis

PROBLEM | CAUSE | REMEDY | |

Compressor and Condenser | Power failure. | Call power company. | |

Fan Will Not Start. | Fuse blown or circuit breaker tripped. | Replace fuse or reset circuit breaker. | |

| |||

| Defective thermostat, contactor, transformer, or control | Replace component. | |

| relay. |

| |

| Insufficient line voltage. | Determine cause and correct. | |

| Incorrect or faulty wiring. | Check wiring diagram and rewire correctly. | |

| Thermostat setting too high. | Lower thermostat setting below room temperature. | |

Compressor Will Not Start | Faulty wiring or loose connections in compressor | Check wiring and repair or replace. | |

but Condenser Fan Runs. | circuit. |

| |

| Compressor motor burned out, seized, or internal | Determine cause. Replace compressor. | |

| overload open. |

| |

| Defective overload. | Determine cause and replace. | |

| Compressor locked out | Determine cause for safety trip and reset lockout. | |

| One leg of | Replace fuse or reset circuit breaker. | |

|

| Determine cause. | |

Compressor Cycles | Refrigerant overcharge or undercharge. | Recover refrigerant, evacuate system, and recharge to | |

(other than normally |

| nameplate. | |

satisfying thermostat). |

|

| |

Defective compressor. | Replace and determine cause. | ||

| |||

| Insufficient line voltage. | Determine cause and correct. | |

| Blocked condenser. | Determine cause and correct. | |

| Defective overload. | Determine cause and replace. | |

| Defective thermostat. | Replace thermostat. | |

| Faulty | Replace. | |

| Restriction in refrigerant system. | Locate restriction and remove. | |

Compressor Operates | Dirty air filter. | Replace filter. | |

continuously. |

|

| |

Unit undersized for load. | Decrease load or increase unit size. | ||

| |||

| Thermostat set too low. | Reset thermostat. | |

| Low refrigerant charge. | Locate leak, repair, and recharge. | |

| Air in system. | Recover refrigerant, evacuate system, and recharge. | |

| Condenser coil dirty or restricted. | Clean coil or remove restriction. | |

Excessive Head Pressure. | Dirty air filter. | Replace filter. | |

| Dirty condenser coil. | Clean coil. | |

| Refrigerant overcharged. | Recover excess refrigerant. | |

| Faulty TXV. | 1. Check TXV bulb mounting and secure tightly to suction line. | |

|

| 2. Replace TXV if stuck open or closed. | |

| Air in system. | Recover refrigerant, evacuate system, and recharge. | |

| Condenser air restricted or air | Determine cause and correct. | |

Head Pressure Too Low. | Low refrigerant charge. | Check for leaks, repair, and recharge. | |

| Restriction in liquid tube. | Remove restriction. | |

Excessive Suction Pressure. | High heat load. | Check for source and eliminate. | |

| Faulty TXV. | 1. Check TXV bulb mounting and secure tightly to suction line. | |

|

| 2. Replace TXV if stuck open or closed. | |

| Refrigerant overcharged. | Recover excess refrigerant. | |

Suction Pressure Too Low. | Dirty air filter. | Replace filter. | |

| Low refrigerant charge. | Check for leaks, repair, and recharge. | |

| Metering device or low side restricted. | Remove source of restriction. | |

| Faulty TXV. | 1. Check TXV bulb mounting and secure tightly to suction line. | |

|

| 2. Replace TXV if stuck open or closed. | |

| Insufficient evaporator airflow. | Increase air quantity. Check filter and replace if necessary. | |

| Temperature too low in conditioned area. | Reset thermostat. | |

| Replace. |

LEGEND

TXV — Thermostatic Expansion Valve

57