MODEL 54e pH/ORP | SECTION 6.0 |

| THEORY OF OPERATION |

6.9PID CONTROL (continued)

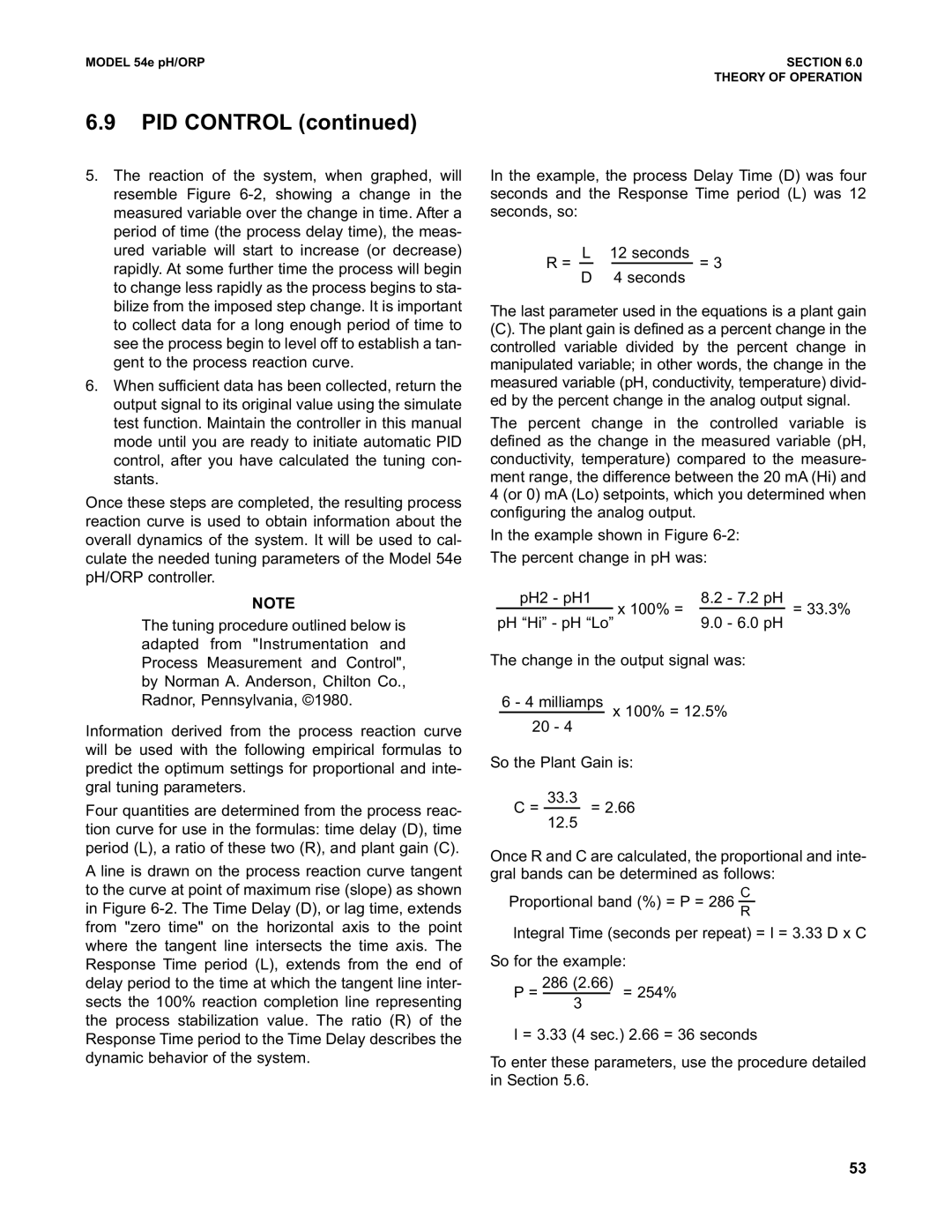

5.The reaction of the system, when graphed, will resemble Figure

6.When sufficient data has been collected, return the output signal to its original value using the simulate test function. Maintain the controller in this manual mode until you are ready to initiate automatic PID control, after you have calculated the tuning con- stants.

Once these steps are completed, the resulting process reaction curve is used to obtain information about the overall dynamics of the system. It will be used to cal- culate the needed tuning parameters of the Model 54e pH/ORP controller.

NOTE

The tuning procedure outlined below is adapted from "Instrumentation and Process Measurement and Control", by Norman A. Anderson, Chilton Co., Radnor, Pennsylvania, ©1980.

Information derived from the process reaction curve will be used with the following empirical formulas to predict the optimum settings for proportional and inte- gral tuning parameters.

Four quantities are determined from the process reac- tion curve for use in the formulas: time delay (D), time period (L), a ratio of these two (R), and plant gain (C).

A line is drawn on the process reaction curve tangent to the curve at point of maximum rise (slope) as shown in Figure

In the example, the process Delay Time (D) was four seconds and the Response Time period (L) was 12 seconds, so:

R = L 12 seconds = 3

D4 seconds

The last parameter used in the equations is a plant gain

(C). The plant gain is defined as a percent change in the controlled variable divided by the percent change in manipulated variable; in other words, the change in the measured variable (pH, conductivity, temperature) divid- ed by the percent change in the analog output signal.

The percent change in the controlled variable is defined as the change in the measured variable (pH, conductivity, temperature) compared to the measure- ment range, the difference between the 20 mA (Hi) and 4 (or 0) mA (Lo) setpoints, which you determined when configuring the analog output.

In the example shown in Figure

The percent change in pH was:

pH2 - pH1 | x 100% = | 8.2 | - 7.2 pH | = 33.3% | |

|

|

|

| ||

pH “Hi” - pH “Lo” | 9.0 | - 6.0 pH |

| ||

The change in the output signal was:

6 - 4 milliamps x 100% = 12.5%

20 - 4

So the Plant Gain is:

C = 33.3 = 2.66 12.5

Once R and C are calculated, the proportional and inte- gral bands can be determined as follows:

Proportional band (%) = P = 286 CR

Integral Time (seconds per repeat) = I = 3.33 D x C

So for the example:

P = 286 (2.66) = 254% 3

I = 3.33 (4 sec.) 2.66 = 36 seconds

To enter these parameters, use the procedure detailed in Section 5.6.

53