MON 20/20

MON 20/20 Software for Gas Chromatographs

Warranty

Important Instructions

This page is intentionally left blank

Table of Contents

Using the hardware functions

Using the Application functions

Section Logs and reports

Section Controlling Analyses

Section Using MON 20/20 Tools

Appendix a Component Data Table Appendix B Data computations

Getting started

MON20/20 Software for Gas Chromatographs

What’s new in MON 20/20

MON20/20 Software for Gas Chromatographs

MON20/20 Software for Gas Chromatographs

System requirements

Getting started with MON 20/20

Registering MON 20/20

Installing MON 20/20

Launching MON 20/20

Register MON 20/20 window,

Select Program Settings... from the File menu

Setting up the data folder

GC directory file not found message

Configuring MON 20/20 to connect to a gas chromatograph

GC directory window

MON20/20 Software for Gas Chromatographs

Export GC Directory

Importing or exporting the GC directory table

GC directory file not found message

Launching MON 20/20 from the SNAP-ON for DeltaV

10.The Device Connection View

11.Right-click to view context menu

Launching MON 20/20 from the AMS Device Manager

12.Device Explorer

13.Right-click to view the context menu

MON 20/20 user interface

14.Features of the MON 20/20 main window

Main user interface

Function of the shortcut icons on the Toolbar

MON20/20 Software for Gas Chromatographs

GC Status Bar

Connecting to a gas chromatograph

18.The Connect to GC window

Login dialog appears

Disconnecting from a gas chromatograph

Keyboard commands

You can use the following function keys from the main window

Task or Data Item Sections Menu Path Keystroke

Procedures guide

Task or Data Item Sections Menu Path Keystroke

MON20/20 Software for Gas Chromatographs

Editing a configuration file

Configuring a gas chromatograph

21.MON 20/20 in offline edit mode

Importing a configuration file

Saving a gas chromatograph’s current configuration

22.Restore to Factory Settings warning message

Restoring the GC to its factory settings

Configuring your printer

Viewing the Physical Name column

Using online help

Operating modes for MON 20/20

Select the Show Physical Names checkbox

26.The Heater window showing Physical Name column

Selecting the GC’s networking protocol

27.The Program Settings window

28.Example of a context-sensitive variable selector

Using the context-sensitive variable selector

30.Third-level drop-down list

32.Variable selected

Viewing chromatograms

Using the chromatograph functions

Chromatogram window

Data displayed in the chromatogram window

Select Chromatogram Viewer... from the Chromatograph menu

Viewing a live chromatogram

View Current CGM

Chromatogram Viewer

Viewing an archived chromatogram

October

Click GC Archive. The Select archive files window appears

Select window

Chromatogram Viewer displaying an archived chromatogram

Protecting or unprotecting an archived chromatogram

Select archive files window

Edit Description window

10.The Select archive files window

11.The Select window

Viewing a saved chromatogram

12.The Chromatogram Viewer displaying a saved chromatogram

Working with the graph

Command Name Shortcut Description

Graph bar

Editing the display properties of the chromatograph

Following table lists the parameters that can be edited

14.A chromatogram

Command Description

Additional plot commands

Mini-plot window

Editing a chromatogram trace

Working with a chromatogram

Click Edit. The Edit Chromatogram dialog appears

18.Chromatogram pull-down menu

Viewing chromatogram results

19.The results window

20.Chromatogram pull-down menu

Saving a chromatogram trace

22.Chromatogram pull-down menu

Removing a chromatogram trace from view

23.Chromatogram pull-down menu

Forcing a calibration

MON20/20 Software for Gas Chromatographs

25.Chromatogram pull-down menu

Opening a comparison file

Saving a comparison file

27.Miscellaneous options

Miscellaneous commands

Name Description

Working with the Timed Events table

Editing Timed Events from the Chromatogram Viewer

Editing Timed Events from the Time Events window

These options are only avialable while in edit mode

Cursor coordinates

MON20/20 Software for Gas Chromatographs

Working with the Component Data Table

Viewing raw data

Editing retention times from the Chromatogram Viewer

Following data displays for each peak from the trace

Setting the gas chromatograph’s date and time

31.The View/Set Date Time window

32.The View/Set Date Time window

Adjusting daylight savings

MON20/20 Software for Gas Chromatographs

MON20/20 Software for Gas Chromatographs

Using the hardware functions

Heaters window

Renaming a heater

Setting the heater’s type

Monitoring the temperature of a heater

Monitoring the operational status of a heater

Setting the desired temperature

Setting PWM Output

Heaters window

Removing a heater from service

Renaming a valve

Configuring the valves

Type in a new descriptive name for the valve Click OK

Valves window

Setting a valve’s operational mode

10.The Valves window

Monitoring the operational status of a valve

11.The Valves window

Inverting the polarity of a valve

12.The Valves window

Setting the usage mode for a valve

MON20/20 Software for Gas Chromatographs

Controlling the detectors

Following data displays for each detector

Offsetting the baseline

14.The Detectors window

Igniting the FID flame

Balancing the preamp

Resetting the preamp value

15.The Detectors window

Renaming a discrete input

Managing your gas chromatograph’s discrete inputs

16.The Discrete Inputs window

Setting a discrete input’s operational mode

To set a discrete input’s operational mode, do the following

18.The Discrete Inputs window

Monitoring the operational status of a discrete input

19.The Discrete Inputs window

Inverting the polarity of a discrete input

Renaming a discrete output

Managing your gas chromatograph’s discrete outputs

Setting a discrete output’s operational mode

21.The Discrete Outputs window

22.The Discrete Outputs window

Monitoring the operational status of a discrete output

23.The Discrete Outputs window

Setting the usage mode for a discrete output

Managing your gas chromatograph’s analog inputs

24.The Analog Inputs window

Renaming an analog input

25.The Analog Inputs window

Setting a analog input’s operational mode

Setting the type of analog input signal

Setting the scale values for an analog input device

27.The Analog Inputs window

28.The Analog Inputs window

Monitoring the status of an analog input

29.The Analog Inputs window

Calibrating an analog input

Click Next. of the Analog Input Calibration Wizard displays

Click Finish. The calibration is complete

Renaming an analog output

Managing your gas chromatograph’s analog outputs

35.The Analog Outputs window

Setting a analog output’s operational mode

36.The Analog Outputs window

Setting the scale values for an analog output device

37.The Analog Outputs window

Mapping a system variable to an analog output

38.The Analog Outputs window with Variable drop-down menu

Monitoring the status of an analog output

40.The Analog Outputs window

Calibrating an analog output

41.The Analog Output Calibration Wizard

43. of the Analog Output Calibration Wizard

44. of the Analog Output Calibration Wizard

Reviewing the Hardware Inventory List

45.The Installed Hardware window

MON20/20 Software for Gas Chromatographs

This page is intentionally left blank

Using the Application functions

System window

Managing the system

Field Name Description

Hhmmss

Managing Component Data Tables

Selected component data table

Editing a Component Data Table

Parameter Description

MON20/20 Software for Gas Chromatographs

MON20/20 Software for Gas Chromatographs

Adding a component to a Component Data Table

Selected component data table

Removing a component from a Component Data Table

Viewing the standard values for a component

Selected component data table

Click Close

11.The Select dialog

Following data displays for each peak

Managing timed events

MON20/20 Software for Gas Chromatographs

14.The Timed Events window

Editing valve events

16.The Timed Events window

Editing integration events

17.The Timed Events Tables selector window

18.The Timed Events window

Has a slight slope. Default

Editing spectrum gain events

19.The Timed Events Tables selector window

20.The Timed Events window

Setting the cycle and analysis time

MON20/20 Software for Gas Chromatographs

Removing an event from the Timed Event Table

MON20/20 Software for Gas Chromatographs

Adding an event to the Timed Event Table

26.The Timed Events window

27.The Validation Data window

Managing Validation Data Tables

28.No components warning

Managing calculations

Setting standard calculations by stream

29.The Control Calculations window

Editing average calculations

30.The Averages Calculations window

Custom Hours setting overrides the Reset Time setting

31.The Averages Calculations window

Viewing an archive of averages for a given variable

32.The archive data window

33.The Averages Calculations window

Copying stream settings

34.No streams available warning

Copying component settings

35.The Averages Calculations window

36.No components available warning

Creating Custom Calculations

Click Edit. The Edit User-defined Calculation window appears

38.The Edit User-defined Calculation window

Click Delete Line to delete the selected line

39.Expression Editor No Action

43.Calculator functions

This section contains the following keys

Inserting a Comment

44.Edit Comment mode

46.An example of a conditional statement

Inserting a Conditional Statement

48.Edit Expression area

49.the Variable/Constant drop-down list

Variable = Regular expression

Inserting an Expression

52.The Final Result tree view

54.The Calculation Steps Viewer

Creating a Constant

55.The Edit Constants window

56.The Edit Temporary Variables window

Creating or Editing a Temporary Variable

57.The Expression Editor

Inserting a System Variable

58.System Variables drop-down menu

Using User-defined Calculations

59.The Expression Editor

GPA ISO GPA & ISO

Setting the calculation method

PSI

Setting alarm limits

61.The Limit Alarms window

62.No streams available warning

63.No components available warning

Managing system alarms

64.The Limit Alarms window

Designating how a stream will be used

Managing streams

65.The Streams window

66.The Streams window

67.The Streams window

Assigning a data table to a particular stream

Changing the base pressure for a stream

Creating a stream sequence for a detector

69.The Stream Sequence window

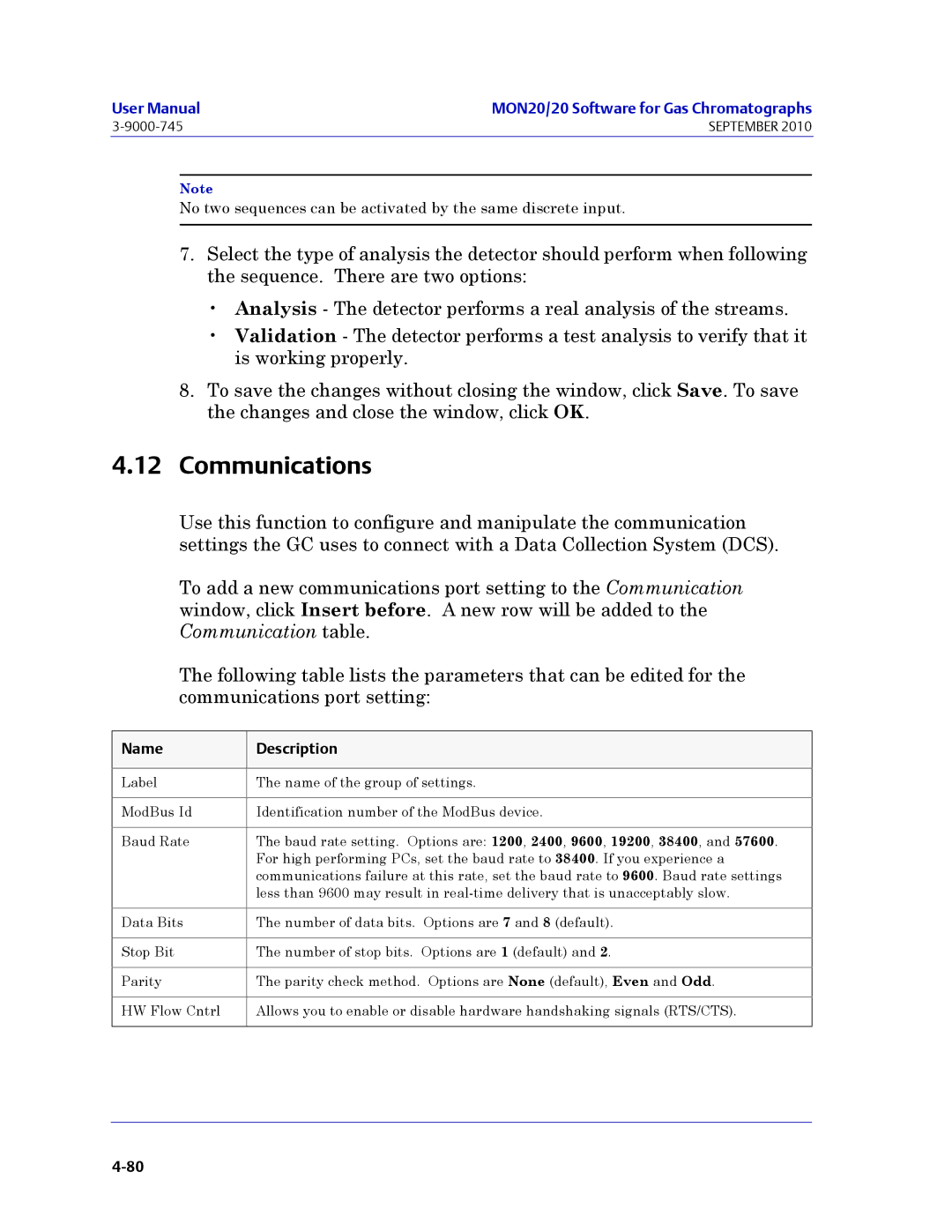

Communications

Metric

Creating or editing registers

To map GC data to Modbus registers, do the following

72.The Modbus Map Editor window

Rdwr

73.Conflicting registers warning

75.The Communication window

Creating a new map file

76.The Modbus Map Editor window

77.The Modbus Map Editor window

78.The Open window

Than Float require only one register per variable

80.Conflicting registers warning

Viewing or editing scales

Assigning a variable to a register

82.The Edit Scales window

To edit or create your own scale, do the following

Following table describes the ethernet ports’ parameters

Configuring the gas chromatograph’s Ethernet port

85.The LOI Status Variables window

Working with local operator interface variables

MON20/20 Software for Gas Chromatographs

86.The FFB PV Mappings window

Mapping Foundation Fieldbus variables

MON20/20 Software for Gas Chromatographs

100

Logs and reports

Viewing and clearing alarms

Viewing unacknowledged and active alarms

Acknowledging and clearing alarms

Viewing the alarm log

Alarm Log window supplies the following data for each alarm

To view a list of alarms, do the following

Maintenance Log window

Viewing the maintenance log

Adding an Entry to the Maintenance Log

Deleting an entry from the maintenance log

Viewing and editing the parameter list

Working with the parameter list

Parameter List window

Parameter List window

Importing and exporting the parameter list

Tiff

Working with drawings and documents

Drawings/Documents window

Select the drawing to view from the drop-down list

Viewing drawings or documents

11.The File Viewer

12.The Drawings/Documents window

Adding files to the GC

13.The Drawings/Documents window

Deleting files from the GC

14.The Event Log window

Viewing the event log

To view the list of change events, do the following

15. The Event Log

Understanding report types

Displaying reports

MON20/20 Software for Gas Chromatographs

MON20/20 Software for Gas Chromatographs

16.Analysis GPA sample report

17.Analysis ISO sample report

18.Calibration sample report

19.Final Calibration sample report

20.Validation sample report

21.Final Validation sample report

22.RawData sample report

Viewing reports from live data

MON20/20 Software for Gas Chromatographs

24.The report window

25.The Report Display window

Viewing a saved report

TXT RPT HTM Html MHT

Viewing reports based on archived data

27.The Analysis/Calibration Archive Report window

28.The Analysis/Calibration Archive Report window

29.The report window

Viewing average reports based on archived data

30.The Analysis/Calibration Archive Report window

TXT HTM Html MHT

Printing reports automatically

MON20/20 Software for Gas Chromatographs

Viewing live trend data

Viewing trend data

Click Trend. The Select records for Trending window displays

33.The Select records for Trending window

34.The Trend Data window with graphs

35.The Trend Data window

Viewing saved trend data

36.The Trend Data window

Working with the Trend Graph

Command Name Shortcut Description

Ctrl + F9

37. The graph

Editing the display properties of the graph

38.The Edit Graph window

Command Description Default Value

39. Primary axes

40. The Trend bar

Working with a trend graph

41.The Trend pull-down menu

Editing a trend graph

43.The Edit Description window

Entering a description for a trend graph

44.The Trend pull-down menu

Saving a trend trace

Displaying trend data

Removing a trend graph from view

Table contains the following columns

47.The Trend Data window

48.The GC Config Report window

Generating a GC Configuration Report

Select the type of output you want for the report

Sample

Sample

H2S

Pentane Area Cal 4017.9700 3715.5801

Sample

Slope Sens Peak Width Inhibit

TEV Type

Inhibit 13.0 13.5

Kg/m3 Calculation

Label Cal Freq Start Time

Alarm High 12.19999981

Alarm High Label

Alarm False MSGSWITCH3Out of Range4Intern Al Error

CDT TEV

Analog Output

Invert Start Time Duration

SCALEDFP10

SCALEDFP11

BTU

Float Rdwr

Home/Daniel/ReportTemplates/DefaultAnalysisReport.xml

Deleting archived data from the gas chromatograph

49.The Reset Archive Data window

Molecular weight vs. response factor graph

50.Molecular Weight vs. Response Factor window

This page is intentionally left blank

MON20/20 Software for Gas Chromatographs

Halting an analysis

Controlling Analyses

Confirmation message

Auto sequencing

Select Auto Sequence... from the Control menu

Analyzing a single stream

Calibrating the gas chromatograph

Start Calibration window

Validating the Gas Chromatograph

10.The Start Validation window

Click Yes and the current analysis stops

Stopping an Analysis Run

This page is intentionally left blank

Using the Modbus Test program

Using MON 20/20 Tools

SIM2251 UserModbus

Comparing Modbus protocols

Setting communication parameters

Click Port Setup. The Port Setup window appears

Getting Modbus Data

Type the starting register value in the Data Addr field

Transmitting using a single data type

Type the starting register value in the Data Addr field

Register Range Default Type

Transmitting using a template

Type the starting register value in the Data Addr field

Data Type Setting Other Settings Result

Setting the log parameters

Log Data window

Saving Modbus data

Troubleshooting communication errors

Printing Modbus data

Assigning scale ranges to UserModbus registers

Click Error.... The Error window appears

Managing users

Menu Commands Admin Super Regular Read-Only User

Menu Commands Admin Super Regular Read-Only User

Creating users

User Administration window

Add User window

Exporting a list of user profiles

Click Export File. The Export User File window displays

Export User File window

Importing a list of user profiles

Click Import File. The Import User File window displays

Navigate to where the file is located, if necessary

Editing users

12.The User Administration window

13.The Edit User window

Removing a user

14.The User Administration window

Changing a user’s password

15.The Change User Password window

Resetting the adminstrator password

Click Yes. The Connect to GC window displays

18.The MON 20/20 Password Reset window

Finding out who is connected to the gas chromatograph

Upgrading the firmware

21.The Upgrade Firmware window

MON20/20 Software for Gas Chromatographs

Viewing diagnostics

Cold booting

23.The Diagnostics window

24.The LOI Key Sensitivity window

Adjusting the sensitivity of the LOI Keys

25.The Roc Cards window

Setting the ROC card type

MON20/20 Software for Gas Chromatographs

MON20/20 Software for Gas Chromatographs

Appendix A, Component Data Table

Mol

Component Name Vapor Gas Liquid

NO2

Octane Oxygen

Table A-2 ISO Component Data Table

HCL

NO2

MON

This page is intentionally left blank

Data acquisition

Appendix B, Data computations

Peak detection

Analysis computations

Calibration

Concentration analysis with response factor

Calculation in mole percent w/o normalization

Liquid equivalent computations

Post analysis computations

Drybtu

Heating value calculations

Corrdrybtu =

CorrDryBTU = ⎛ DryBTUatBasePressure ⎞ ⎛ ContractPressure ⎞

Corrgrossbtu

∑ Conc i VP

∑ LVpercentiLRDi

ResponseFactor = AP 3 + bP 2 + cP + d

Multi-level calibration

Indirect calibration

UserModbus register list

Appendix C, Modbus registers list

Table C-2 List of UserModbus Registers

DET1

MON20/20 Software for Gas Chromatographs

MON20/20 Software for Gas Chromatographs

MON20/20 Software for Gas Chromatographs

Reg. No Description

SIM2251 Modbus register list

MON20/20 Software for Gas Chromatographs

Modbus registers list

3056

Reg. No Description

MON20/20 Software for Gas Chromatographs

October

Reg

9000-745

MON20/20 Software for Gas Chromatographs

GPA system variables

Appendix D, Basic and advanced system variables

System Reference Manual 700XA Gas Chromatograph

700XA Gas Chromatograph System Reference Manual

System Reference Manual 700XA Gas Chromatograph

700XA Gas Chromatograph System Reference Manual

System Reference Manual 700XA Gas Chromatograph

700XA Gas Chromatograph System Reference Manual

System Reference Manual 700XA Gas Chromatograph

TEV

ISO system variables

700XA Gas Chromatograph System Reference Manual

System Reference Manual 700XA Gas Chromatograph

700XA Gas Chromatograph System Reference Manual

System Reference Manual 700XA Gas Chromatograph

700XA Gas Chromatograph System Reference Manual

Application Streams Usage

This page is intentionally left blank

700XA Gas Chromatograph

Appendix E, Creating custom calculations

Figure E-2.The Edit User-defined Calculation window

Click Delete Line to delete the selected line

Being performed

Figure E-7.Calculator functions

This section contains the following keys

Inserting a comment

Figure E-8.Edit Comment mode

Figure E-10.An example of a conditional statement

Inserting a conditional statement

Figure E-12.Edit Expression area

Figure E-13.the Variable/Constant drop-down list

Inserting an expression

Figure E-15.Edit Expression area

Figure E-17.The Edit Expression area

Figure E-19.The Edit Constants window

Creating a constant

Figure E-20.The Edit Temporary Variables window

Creating or editing a temporary variable

Inserting a system variable

Figure E-21.The Expression Editor

Using user-defined calculations

Figure E-22.System Variables drop-down menu

Figure E-23.The Expression Editor

MON20/20 Software for Gas Chromatographs

Warranty Claim Procedures

This page is intentionally left blank

Customer Repair Report

Page

This page is intentionally left blank