Part Number L000307

Restricted USE only

Revision Control Date Document Title Number

Capacity

Reviewing the HDP800 Series Printers Overview table

HDP800 Series Input Card Accepted Encoding Lamination

Modules

How to use the manual

Manual Description

To prevent equipment or media damage, always wear an

Safety Messages review carefully

Exposed to static electricity discharges

To prevent equipment or media damage, always remove

Reviewing the HDP 800 Series Block Diagram

HDP 800 Series Card Printer/Encoders Overview

Reviewing HDP 800 Series Card Printer Sequence of Operations

Step Process

Reviewing HDP 800 Series Card Printer Sequence of Operations

Reviewing HDP 800 Series Card Printer Sequence of Operations

Sensor is activated. All off

Sensor

Reviewing the Lamination Module Sequence of Operations

Reviewing the Lamination Module Sequence of Operations

Reviewing Lamination Module Boot up Sequence

Table of Contents

Restricted USE ONLYFargo Electronics, Inc

Card Lamination Module

Restricted USE ONLYFargo Electronics, Inc

Cleaning

Restricted USE ONLYFargo Electronics, Inc

LCD On-Line Menu Navigation

Glossary of Terms Index Appendix a Engineering Drawings

Appendix B Technical Updates 535 Appendix C Miscellaneous

Specifications

Regulatory Compliances

Agency Listings

HDP825/825-LC

Technical Specifications

HDP820/820-LC

Technical Specifications

Technical Specifications

HDP820-LC/825-LC 87 lbs./39.5kg

Functional Specifications

Function Description

Component Description

Component Description

On the next

Softkey Buttons

Print Station Transfer Station

Component Description

Component Description

Refer to the previous table

Printer Components LCD and Softkey Control Pad

Printer Components LCD and Softkey Control Pad

Lamination Module. See Card Lamination Module on

Component Description Cancel

Pause

Printer Components LCD and Softkey Control Pad

Printer Components LCD and Softkey Control Pad

Printer Components Centronics-Type Parallel Interface

Printer Components Print Ribbons

Printer Components Blank Cards

Type Description

Printer Components Card Input Hopper HDP820/820-LC

Printer Components Card Input Hopper HDP825/825-LC

Printer Components Card Output Hopper

Printer Components Lamination Roller

Reviewing the Card Lamination Module

Reviewing the Lamination Top Cover and Station

Component Description Reference

Fast Flashing Green light Indicates

Reviewing the Securing Latches and Lamination LED Light

Solid Green light Indicates the Card

Reviewing the Cancel button

Component Description Reference Cancel

Reviewing the Resume pause button

Component Description Reference Resume

Reviewing the Rejection Card Hopper and Card Output Hopper

Reviewing the Module and Printer interaction

Term Description Reference

Reviewing the Module and LCD Display interaction

Alternate with LAM Temp current

Reviewing the Module’s Programmed Default Temperature

Target Temperature If a print job is

Initial Heating Process The initial

Automatic Reset Whenever

Reviewing the Laminator Temperature Adjustment

New Temperature Settings Once

Consistent Temperature

Thermal Transfer Film The Thermal

Reviewing the Overlaminates

Term Description Cross Reference

PolyGuard Overlaminate PolyGuard

Reviewing the CR-90or CR-100Patch Size

Reviewing the Overlaminate Design

Reviewing LCD Messages

Message Cause Solution

LCD/SmartGuard Messages

Reviewing LCD Messages

Dram

See Card Feeding Errors

Fpga

See Resolving the Temperature

See the Resolving the Failed

See the Resolving the Print

See the Printing a Test Image

Feeding problem procedure

Reviewing SmartGuard Error and Status Messages

Restricted USE only

Step Procedure

Communications Errors

Resolving the Communication Errors

Resolving the Communication Errors

Step

Cause communications errors

Firmware Errors

Resolving the Upgrade Failed error

Resolving an Upgrade Failed error

Card Feeding Errors

Resolving the Card Feeding problem HDP820/820-LC

60mil

Resolving a Card Feeding problem HDP820/820-LC

30mil

Clean the Cleaning Rollers

Resolving the Card Feeding Errors HDP825/825-LC

Resolving the Card Feeding Errors HDP825/825-LC

Insert cards neatly stacked

Resolving the stalled Cards on or at the Feed Rollers

Resolving the jammed Cards on the Flipper Table

Resolving the Flipper Alignment Error Message

Step

Resolving the Card Jam Error Message

Resolving the Card Jam Lam Error Message

Resolving the No Magnetic Encoder Error Message

Magnetic Encoding Errors

Resolving the No ENC Response Error Message

Resolving the Failed Magnetic Encode Error Message

Reset power on the Printer to clear any error messages

Towards the back of the Printer

Sending the Track Information procedure in ,

Card Encoding Errors

Resolving the Job Mismatch error

Flipper Offset may need to be adjusted

Resolving the No Prox Encoder Error Message

Resolving the No Smart Encoder Error Message

Resolving the Failed Smart Encode Error Message

Printing Process Errors

Resolving the Ribbon Alignment Error Message

Resolving the Print Ribbon Error Message

Resolving the Print Ribbon Jam

Resolving the Print Ribbon Out Error Message

Resolving the Wrong Print Ribbon Error Message

Resolving the Unknown Ribbon Type Error Message

Resolving the Headlift Error Message

Resolving the Printer pausing between Panels problem

Resolving the Printhead Temp Error Message

Resolving the Printer Open Error Message

Transfer Process Errors

Resolving the Upper and Lower Film errors

Resolving the Upper and Lower Film errors

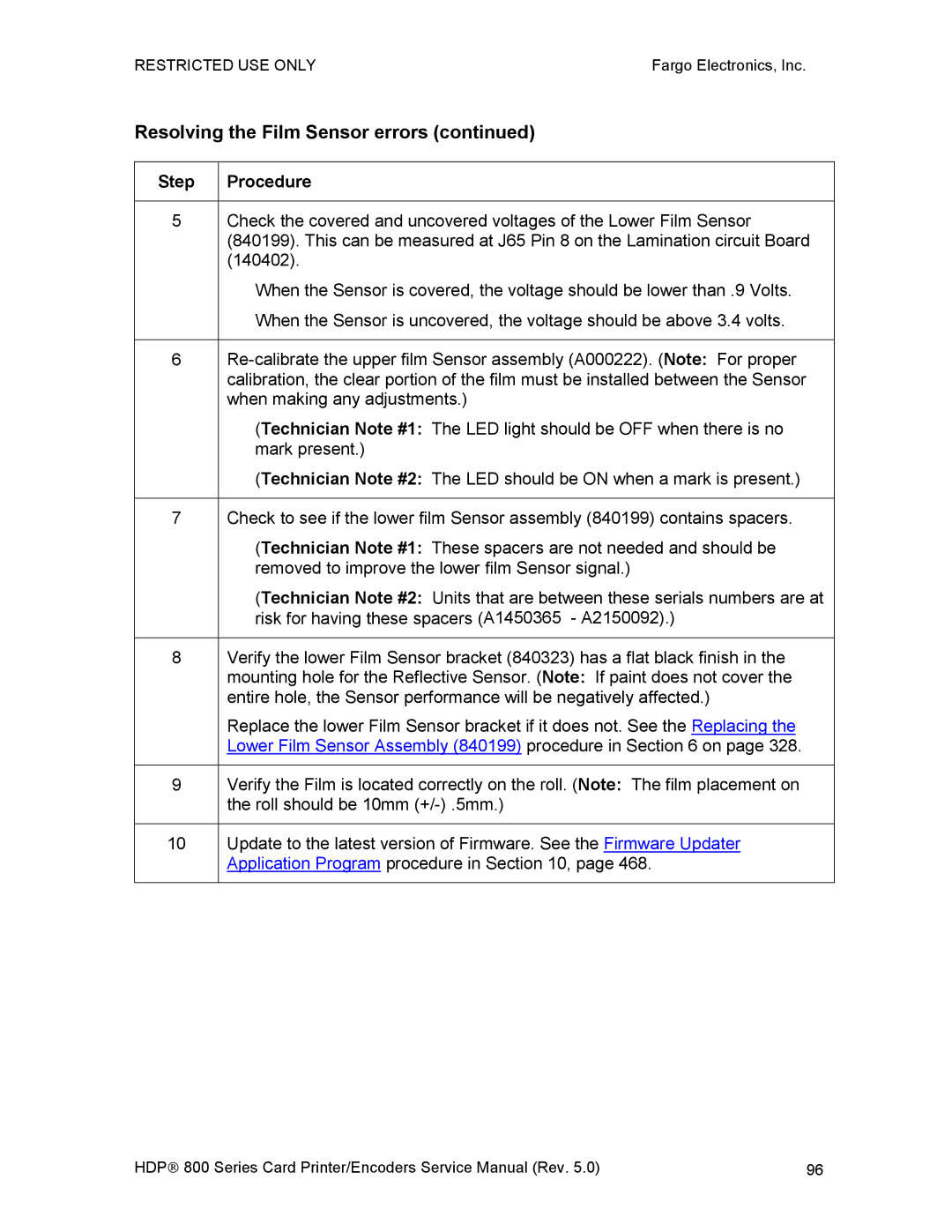

Resolving the Film Sensor errors

Resolving the Film Sensor errors

Resolving the Film Sensor errors

Resolving the Film Sensor errors

Resolving the Transfer Cooling error

Resolving the Card Jam Error Message

Resolving the Temperature Timeout Error Message

Resolving the Transfer Lift Error Message

Resolving the Output Stacker errors

Card Lamination Errors

Resolving the Overlaminate Jam

Resolving the Overlaminate Jam

Resolving the Card Lamination Placement errors

Select MENU, Setup Printer and Lamination TOF

Resolving the Lam Error/Out Error Message

Resolving the Lam Error/Out Error Message

106

Check the Lamination Temperature

Diagnosing the Image Problems

Resolving the Pixel failure problems

Resolving the Pixel failure problems

Resolving the Card surface debris problems

Resolving the Card surface debris problems

Clean the Platen Roller

Resolving the incorrect Image Darkness problems

Resolving the incorrect Image Darkness problems

Resolving the Ribbon wrinkle problems

Resolving the Ribbon wrinkle problems

Resolving the excessive Resin Printing problems

Resolving the incomplete Resin Printing problems

Resolving the HDP Film wrinkle problems

Resolving the HDP Film wrinkle problems

Resolving the incomplete Transfer problems

Resolving an incomplete transfer on the leading edge problem

Resolving the Image Placement problems

Resolving the Image Placement problems

Select Document Defaults

Select Printing Preferences

126

Resolving the poor Image Quality problems

Resolving the Image washout on Film problems

Resolving the Registration problems

Resolving the Registration problems

Resolving the Card Skewed Image problems

Printing a Test Image

Reviewing the Gray/Align YMC/K Self-Test

Reviewing the Color/Resin Ymck Self-Test

Reviewing the Color Bars YMC Self-Test

Reviewing the Card Count Self-Test

Reviewing the Magnetic Test option

Reviewing the Lamination Color/Resin YMCK+L Self-Test

Card Lamination Module

Opening the Card Lamination Module

Opening the Card Lamination Module

139

Take-Up Roll Supply Roll

Loading the Overlaminate

Loading the Overlaminate

142

Adjusting the Card Lamination Module

Adjusting the Card Flattener

Adjusting the Card Flattener

Adjusting the Card Guide Rail

Blank Card Card Flipping Mechanism

Adjusting the Card Guide Rail

147

010/.25mm

Adjusting the Internal Card Guide

Internal Card Guide Blank Card Screws

Adjusting the Internal Card Guide

010/.25mm

Attaching the Card Lamination Module

Remove 3 screws

Attaching the Card Lamination Module

Remove 4 screws

155

156

157

Cable are keyed for one way installation

159

160

Insert 1 screw

Insert Screws

163

Printer Adjustments

Adjusting the Card Size

Adjusting the Card Input Guide

Adjusting the Card Input Guide

168

169

Adjusting the Card Stacker Output Guide

Adjusting the Card Stacker Output Guide

172

173

174

175

Adjusting the Card Thickness Knob

Tools Needed

Fine-Tuning the Card Separator Adjustment Assembly D840995

See Drawing D841087

Printing on Alternate Card stocks

Selecting the Right Cards and optimize the HDP Print Process

Selecting the Appropriate HDP Printer Driver settings

Selecting the appropriate HDP Printer Driver settings

Card/Ribbon Type Transfer Transfer Time Flattener Temp

Conducting the Tape Adhesion Test

Conducting the Tape adhesion Test

183

Installing Printer Driver Updates

Printer Driver Options

Installing Printer Driver Updates

Setting up Windows NT/Windows 2000/Windows XP

Setting Up the Printer Driver

Setting up Windows 98SE/Windows Millennium

Using the Device Options tab

Adjusting the Ribbon Type

Adjusting the Film Type

Adjusting for the color matching

Adjusting for the Resin Dither

Using the Print Both Sides option

Using the Split 1 Set of Ribbon Panels option

Using the Print Back Side First option

Using the Print on Back Side Only option

196

Using the Print in Single Card Mode option

Using the Link Card to Print Job option

Using the Disable Printing option

Using the Image color tab

Using the Image color tab

202

203

Using the Image Transfer tab

Adjusting the Image Position controls

Adjusting the Image Position controls

Adjusting the Transfer Dwell Time and Temperature

Adjusting the Flattener Temperature

Using the K Panel Resin tab

Selecting the Full Card with the K Panel Resin tab

Selecting the Defined Areas with the K Panel Resin tab

Selecting the Undefined Areas with the K Panel Resin tab

Defining the Area to activate the Card Grid

Measuring the Total Card area

=1.4 Y=0.2

Access Level-2 ID#

Measuring the Area to be positioned on the Card

Selecting the Print YMC under the K and Print K Only options

Selecting the Print YMC under the K and Print K Only options

Using the Magnetic Encoding tab

Using the Encoding Mode option

Using the Encoding Mode option

Encoding the Mode/Coercivity/Magnetic Track Selection

Reviewing the Magnetic Track Options

Reviewing the Enable MLE Support checkbox

Reviewing the Verification options

Reviewing the Shift Data Left

Reviewing the ISO Track Locations

Sending the Track Information

Valid Characters Number

Reviewing the Sample String

Start End Field Maximum

Reviewing the Ascii Code and Character Table

Using the Card tab

Selecting the Card Size from CR-80, CR-90 or CR-100

Selecting the Card Size from CR-80, CR-90 or CR-100

Selecting the Custom Card Size

Selecting the Card Type

Selecting the Card Type

Reviewing the Orientation

Specifying the Copies

Clicking on the About button

Using the Lamination tab only with Card Lamination Module

Selecting the Lamination Position

Selecting the Lamination Side

Selecting the Lamination Type

Adjusting the Transfer Dwell Time and Transfer Temperature

Selecting the Sensors button and Defaults button

243

Cleaning

Using the Required Supplies

245

Cleaning inside the Printer

Cleaning outside the Printer

Cleaning the Printhead

Printhead

Cleaning the Cleaning Rollers

Cleaning the Cleaning Rollers

250

Close the Printers Front Access Door

Cleaning the Card Feed Rollers

Steps Procedure

Cleaning the Card Feed Rollers additional Feed Rollers

Card Feed Rollers

255

Cleaning the Platen Rollers

Print Platen Roller

Cleaning the Platen Rollers

Transfer Platen Roller

Packing the HDP800 Series Card Printer

Resolving the EE Checksum Error

Board Errors

Resolving the EE Memory Error

Resolving the Fpga Error

Resolving the Dram Memory Error

Resolving the RAM Memory Error

Sensor Testing

Reviewing the Sensor Location and Voltages

Sensor Location Pin Board Low Range VDC High Range VDC

Reviewing the Sensor Layout on Ribbon Sensor array

Reviewing the Sensor Location and Voltages

Flipper Home J42 Lam Covered Uncovered 3.0

Entering the LCD Menu and selecting an Option

Ready HDP820

Softkey Buttons Scroll Buttons

Entering the LCD Menu and Selecting an Option

Selecting from the HDP800 Series Menu Option Structure Tree

Reviewing the Printer Setup

Reviewing the Printer Setup

Select Transfer TOF

Select MENU, Setup Printer

Select the Print Offset button

Aligning the Print Offset

TOF EOF

Aligning the Print Offset

Setting the Transfer TOF

TOF EOF

Setting the Transfer TOF

Setting the Transfer EOF

455

Adjusting the Transfer Tension

Adjusting the Film Drive

Adjusting the Ribbon Tension

Adjust the Transfer Temperature value

Adjusting the Ribbon Drive

Adjusting the Transfer Temperature

Select MENU, Setup Printer and Printhead Resistance

Setting the Flattener Temperature

Setting the Printhead Resistance

Adjusting the Image Darkness

Select MENU, Setup Printer and Image Darkness

Changing the Encoder Settings

Setting the Magnetic TOF

Select MENU, Setup Printer and Magnetic TOF

293 / 7.44mm Magnetic Track Data

Adjusting the Flipper Offset

Adjusting the Lamination Flipper Offset

Adjusting the LAM TOF and EOF

Show the Error Count

Adjusting the Lamination Sensor Calibration

Adjusting the Lamination Temperature Setting

Error LOG

LCD will prompt Are you sure you want to continue?

Using the Show Card Count option

System Upgrade Firmware Upgrade

Firmware Updates

Firmware Updater Application Program

Firmware Updater Application Program

Downloading Firmware Updates

Updating the Printers Firmware

Updating the Main Firmware

Updating the Main Firmware

Failed or Upgrade Firmware Now on boot up

Upgrade Firmware Now on boot up

Updating the LCD Firmware

Updating the LCD Firmware

Firmware Upgrades as of 10/07/03

For smudging, follow this procedure

Firmware Upgrades as of 10/07/03

For flashing, follow this procedure

For chipping of the card image, follow this procedure

Fargo Technical Support

Contacting Fargo Technical Support

Reviewing Example No Serial Number

Finding out when a Fargo Card Printer was manufactured

Reading the Serial Numbers on a Fargo printer

Reviewing Example No Serial Number A1280224

Reviewing Spare Parts Lists

Reviewing Spare Parts List for HDP 800 Series Card Printer

HDP 825 only

Compound

4MM

Lock

Smart Lock

HDP820 Prog

Flex CT HDR

No Louver

484

PRN

Force

JIS2

LAM

486

Only

STP PRN

489

D850466 Roller-Card Feed Roller- Card $29.32 Black

491

ITM-TUP

PRN PSN

OPT PRN

Reviewing Spare Parts List for Card Lamination Module

MXL

Effective Date January

496

497

DTC

LAM Flip

C25/PRO

LED LC

501

Glossary of Terms

Term Definition

Glossary of Terms

504

505

506

Eeprom

Eprom

509

510

ISO

512

513

514

PET

PVC

Ymck

RGB

518

TAC

520

Ymckk

YMC

Ymckh

Ymcko

Index

523

524

525

Gray/Align YMC

527

Magnetic Encoding tab, 218 magnetic stripe

Photo

Print YMC Under K/Print K Only

531

Sending Update to Printer dialog, 473

533

Undefined Areas option, 212 Unknown Ribbon Type, 57 Update

Appendix a Engineering Drawings Appendix B Technical Updates