Basic Operation

Pre-Operation Tasks

Go through the

Table 1:

✓Checklist System grounded

Verify all grounding connections were made. See Grounding, page 19.

All connections tight and correct

Verify all electrical, fluid, air, and system connec- tions are tight and installed according to the man- ual instructions.

Fluid supply containers filled

Check component A and B and solvent supply containers.

Dose valves set

Check that dose valves are set correctly. Start with the settings recommended in Valve Set- tings, page 35, then adjust as needed.

Fluid supply valves open and pressure set

Component A and B fluid supply pressures should be equal unless one component is more viscous and requires a higher pressure setting.

Solenoid pressure set

Power On

1.IS Systems (Alternator Power Supply): Set pump air regulators to minimum setting. Open main air valve to start

Basic Operation

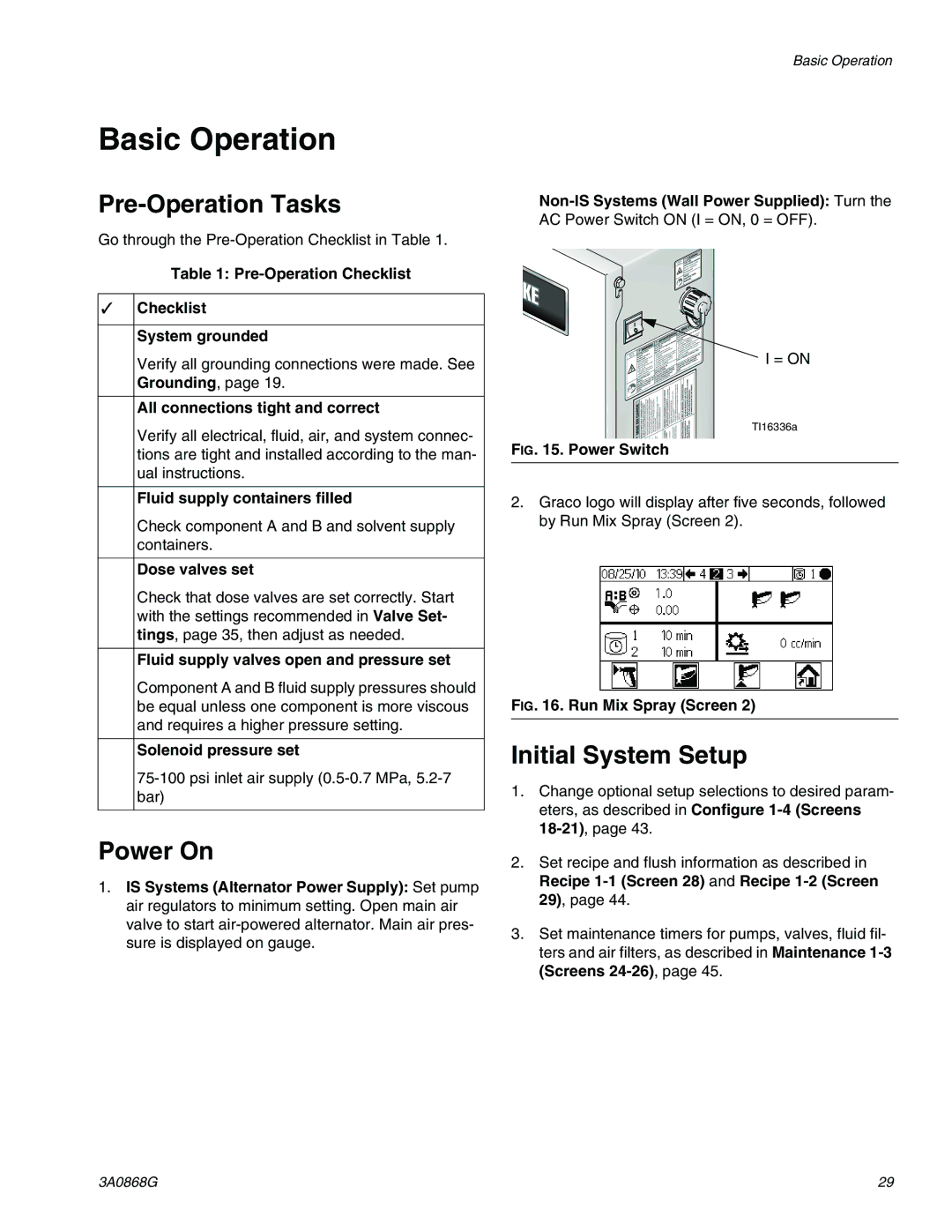

Non-IS Systems (Wall Power Supplied): Turn the

AC Power Switch ON (I = ON, 0 = OFF).

I = ON

TI16336a

FIG. 15. Power Switch

2.Graco logo will display after five seconds, followed by Run Mix Spray (Screen 2).

FIG. 16. Run Mix Spray (Screen 2)

Initial System Setup

1.Change optional setup selections to desired param- eters, as described in Configure

2.Set recipe and flush information as described in Recipe

3.Set maintenance timers for pumps, valves, fluid fil- ters and air filters, as described in Maintenance

3A0868G | 29 |