Basic Operation

10.After the volume for A or B is entered, the ProMix 2KE controller calculates the new pump factor and shows it on Calibration 1 (Screen 22) and Calibra- tion 2 (Screen 23).

11.Before you begin production, clear the system of solvent and prime it with material.

a.Go to Mix mode.

b.Trigger the gun into a grounded metal pail until mixed material flows from the gun nozzle.

If the fluid flow rate is too low: increase air pres- sure to component A and B fluid supplies or increase the regulated fluid pressure of mixed material.

If the fluid flow rate is too high: reduce the air pressure to component A and B fluid supplies, close the dose valves further, or decrease the reg- ulated fluid pressure of mixed material.

4.Turn on atomizing air to the gun. Check the spray pattern as instructed in your spray gun manual.

Spraying |

| NOTE: | ||

|

| |||

NOTE: See Run Mode Details, pages | • Pressure adjustments of each component will | |||

vary with fluid viscosity. Start with the same fluid | ||||

screen information, if needed. | ||||

pressure for component A and B, then adjust as | ||||

|

|

| ||

|

|

| needed. | |

|

|

| • Do not use the first | |

|

|

| material as it may not be thoroughly mixed due | |

1. Calibrate the pumps as described in Pump Calibra- | to errors while priming the system. | |||

| ||||

| tion, page 31. Pump factors will update automati- | NOTICE | ||

| cally based on calibration results. Make additional | |||

| Do not allow a fluid supply tank to run empty. It is pos- | |||

| manual changes, if desired, as described in Cali- | |||

| bration 1 and 2 (Screens 22 and 23), page 46. | sible for air flow in the supply line to turn gear meters | ||

| Adjust the flow rate. | in the same manner as fluid. This can damage the | ||

| meters and lead to the proportioning of fluid and air | |||

|

|

| ||

|

|

| that meets the ratio and tolerance settings of the | |

2. | Press | . The system will load the correct potlife | equipment. This can further result in spraying | |

| volume based on hose length and diameter entered | uncatalyzed or poorly catalyzed material. | ||

|

| |||

| on Configure 2 (Screen 19). Once material is |

| ||

loaded, the system returns to Standby. Press ![]() again to spray the loaded recipe.

again to spray the loaded recipe.

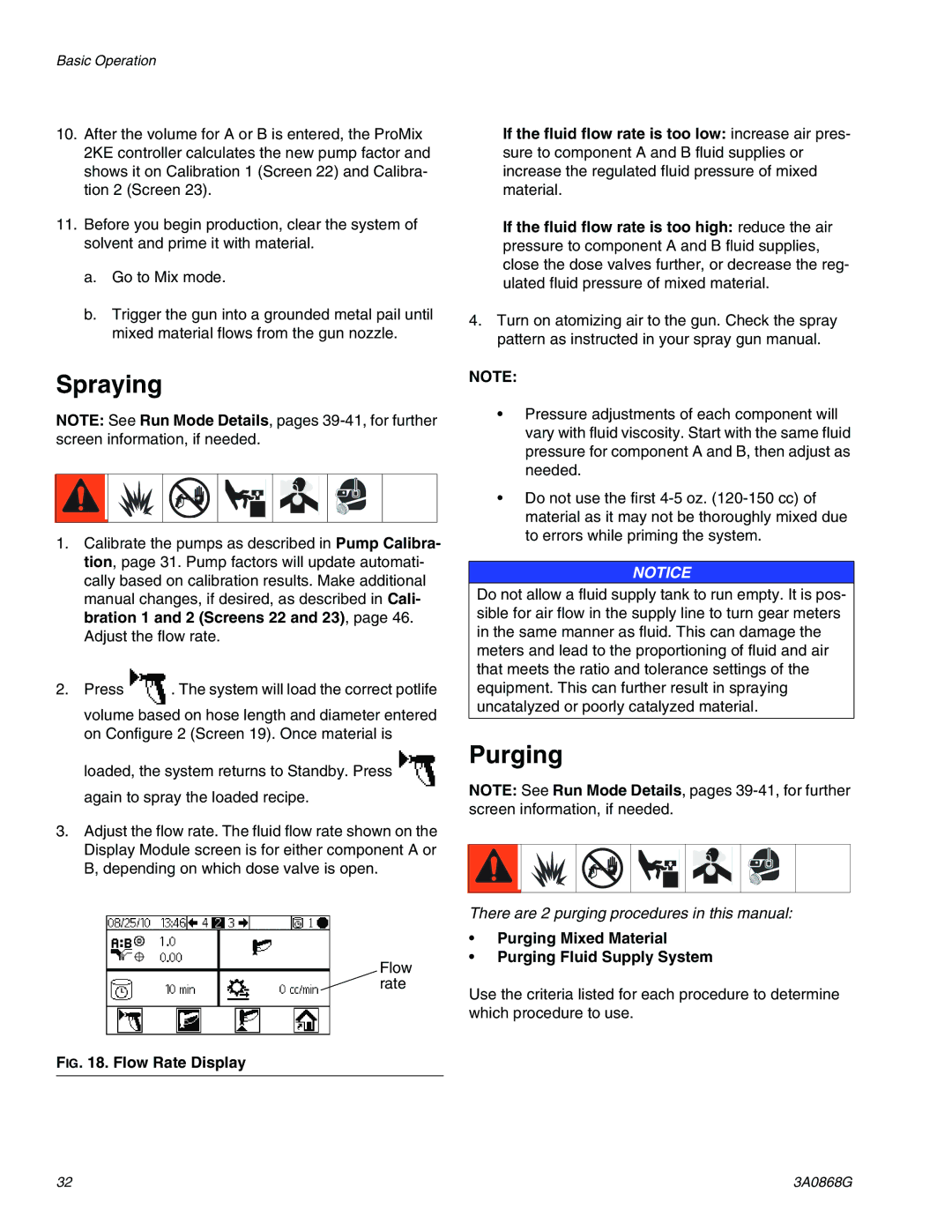

3.Adjust the flow rate. The fluid flow rate shown on the Display Module screen is for either component A or B, depending on which dose valve is open.

Flow rate

Purging

NOTE: See Run Mode Details, pages

There are 2 purging procedures in this manual:

•Purging Mixed Material

•Purging Fluid Supply System

Use the criteria listed for each procedure to determine which procedure to use.

FIG. 18. Flow Rate Display

32 | 3A0868G |