Dynamic Dosing Restrictor Selection Graphs

Dynamic Dosing Restrictor Selection Graphs

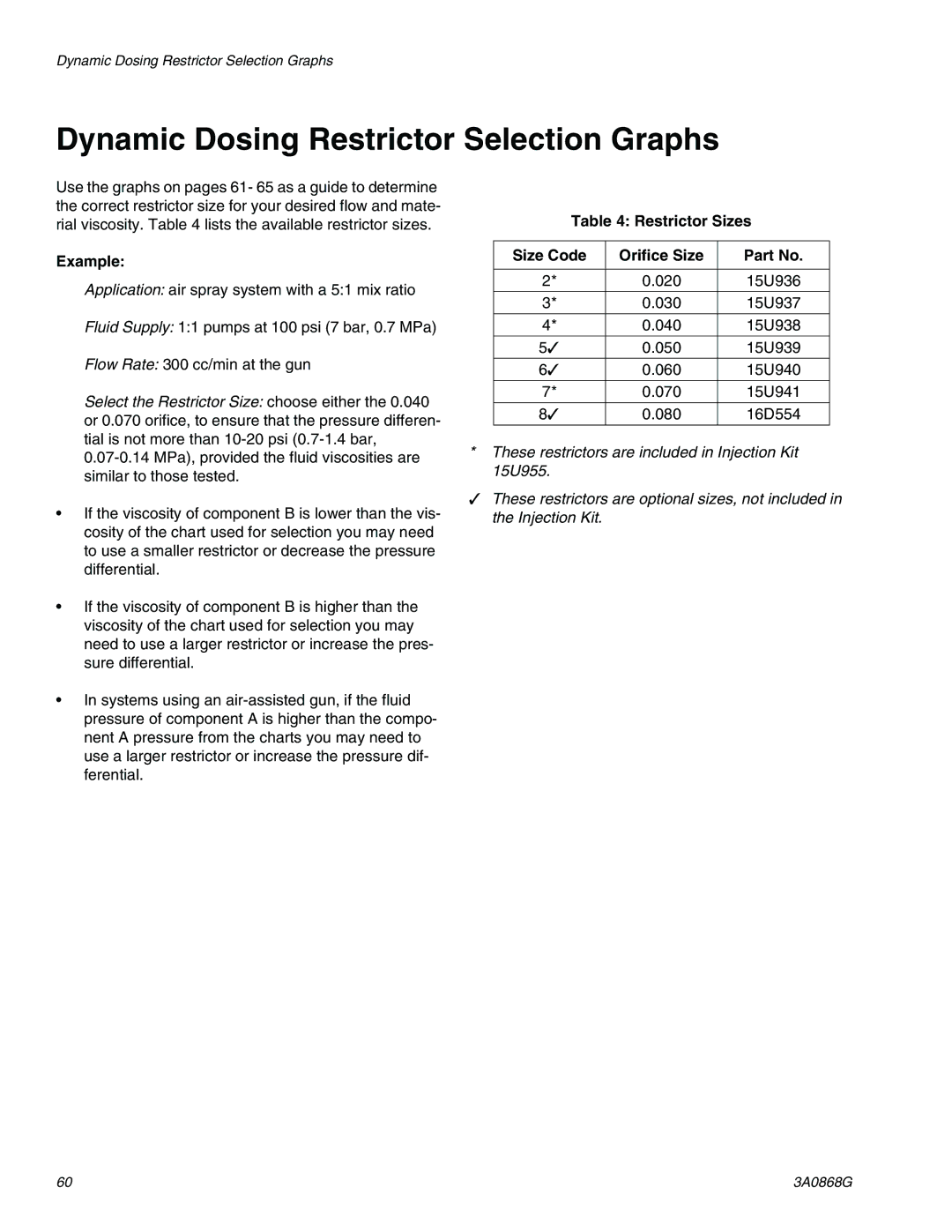

Use the graphs on pages 61- 65 as a guide to determine the correct restrictor size for your desired flow and mate- rial viscosity. Table 4 lists the available restrictor sizes.

Example:

Application: air spray system with a 5:1 mix ratio

Fluid Supply: 1:1 pumps at 100 psi (7 bar, 0.7 MPa)

Flow Rate: 300 cc/min at the gun

Select the Restrictor Size: choose either the 0.040 or 0.070 orifice, to ensure that the pressure differen- tial is not more than

•If the viscosity of component B is lower than the vis- cosity of the chart used for selection you may need to use a smaller restrictor or decrease the pressure differential.

•If the viscosity of component B is higher than the viscosity of the chart used for selection you may need to use a larger restrictor or increase the pres- sure differential.

•In systems using an

Table 4: Restrictor Sizes

Size Code | Orifice Size | Part No. |

|

|

|

2* | 0.020 | 15U936 |

|

|

|

3* | 0.030 | 15U937 |

|

|

|

4* | 0.040 | 15U938 |

|

|

|

5✓ | 0.050 | 15U939 |

|

|

|

6✓ | 0.060 | 15U940 |

|

|

|

7* | 0.070 | 15U941 |

|

|

|

8✓ | 0.080 | 16D554 |

|

|

|

*These restrictors are included in Injection Kit 15U955.

✓These restrictors are optional sizes, not included in the Injection Kit.

60 | 3A0868G |