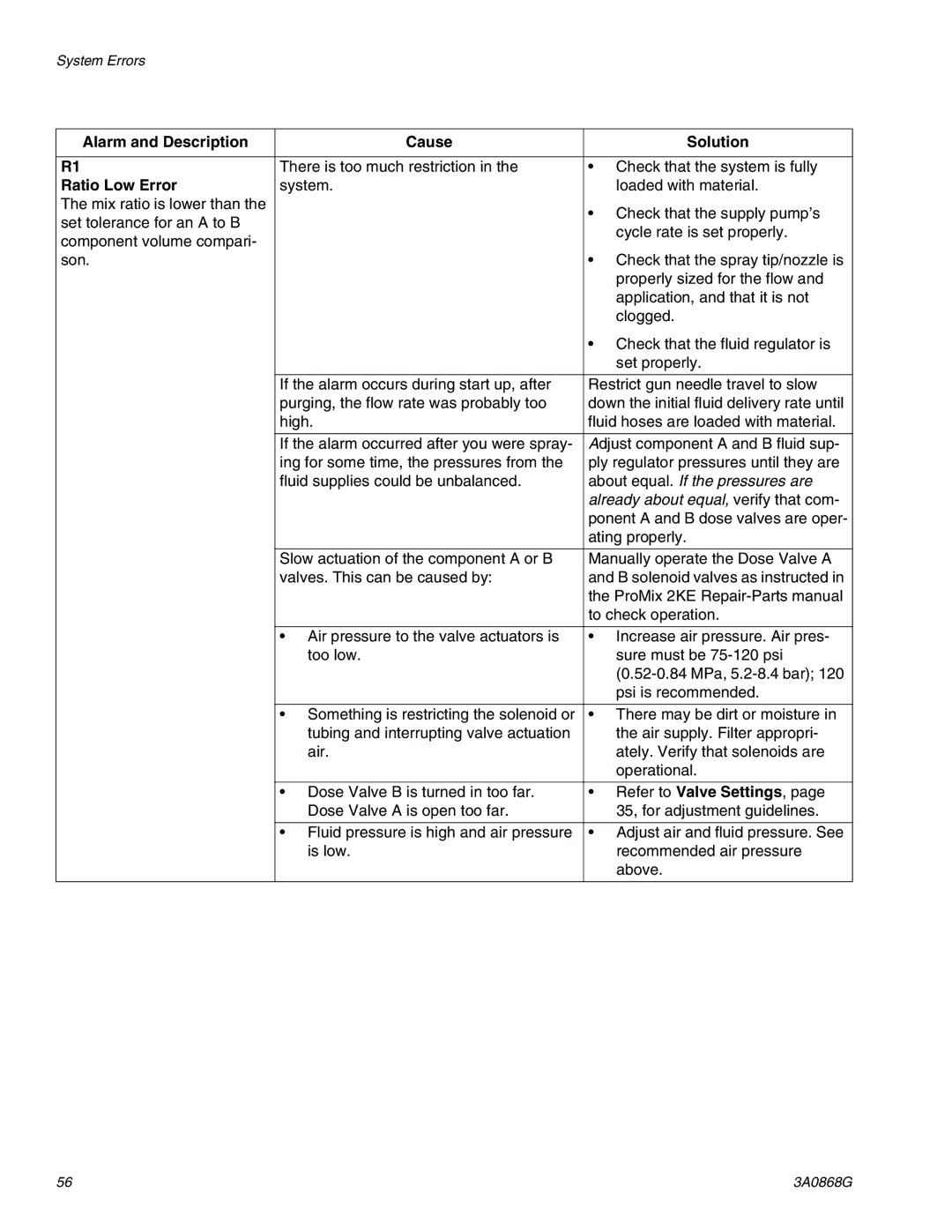

System Errors

Alarm and Description | Cause | Solution |

|

|

|

R1 | There is too much restriction in the | • Check that the system is fully |

Ratio Low Error | system. | loaded with material. |

The mix ratio is lower than the |

| • Check that the supply pump’s |

set tolerance for an A to B |

| |

| cycle rate is set properly. | |

component volume compari- |

| |

|

| |

son. |

| • Check that the spray tip/nozzle is |

|

| properly sized for the flow and |

|

| application, and that it is not |

|

| clogged. |

|

| • Check that the fluid regulator is |

|

| set properly. |

|

|

|

| If the alarm occurs during start up, after | Restrict gun needle travel to slow |

| purging, the flow rate was probably too | down the initial fluid delivery rate until |

| high. | fluid hoses are loaded with material. |

|

|

|

| If the alarm occurred after you were spray- | Adjust component A and B fluid sup- |

| ing for some time, the pressures from the | ply regulator pressures until they are |

| fluid supplies could be unbalanced. | about equal. If the pressures are |

|

| already about equal, verify that com- |

|

| ponent A and B dose valves are oper- |

|

| ating properly. |

|

|

|

| Slow actuation of the component A or B | Manually operate the Dose Valve A |

| valves. This can be caused by: | and B solenoid valves as instructed in |

|

| the ProMix 2KE |

|

| to check operation. |

|

|

|

| • Air pressure to the valve actuators is | • Increase air pressure. Air pres- |

| too low. | sure must be |

|

| |

|

| psi is recommended. |

|

|

|

| • Something is restricting the solenoid or | • There may be dirt or moisture in |

| tubing and interrupting valve actuation | the air supply. Filter appropri- |

| air. | ately. Verify that solenoids are |

|

| operational. |

|

|

|

| • Dose Valve B is turned in too far. | • Refer to Valve Settings, page |

| Dose Valve A is open too far. | 35, for adjustment guidelines. |

|

|

|

| • Fluid pressure is high and air pressure | • Adjust air and fluid pressure. See |

| is low. | recommended air pressure |

|

| above. |

|

|

|

56 | 3A0868G |