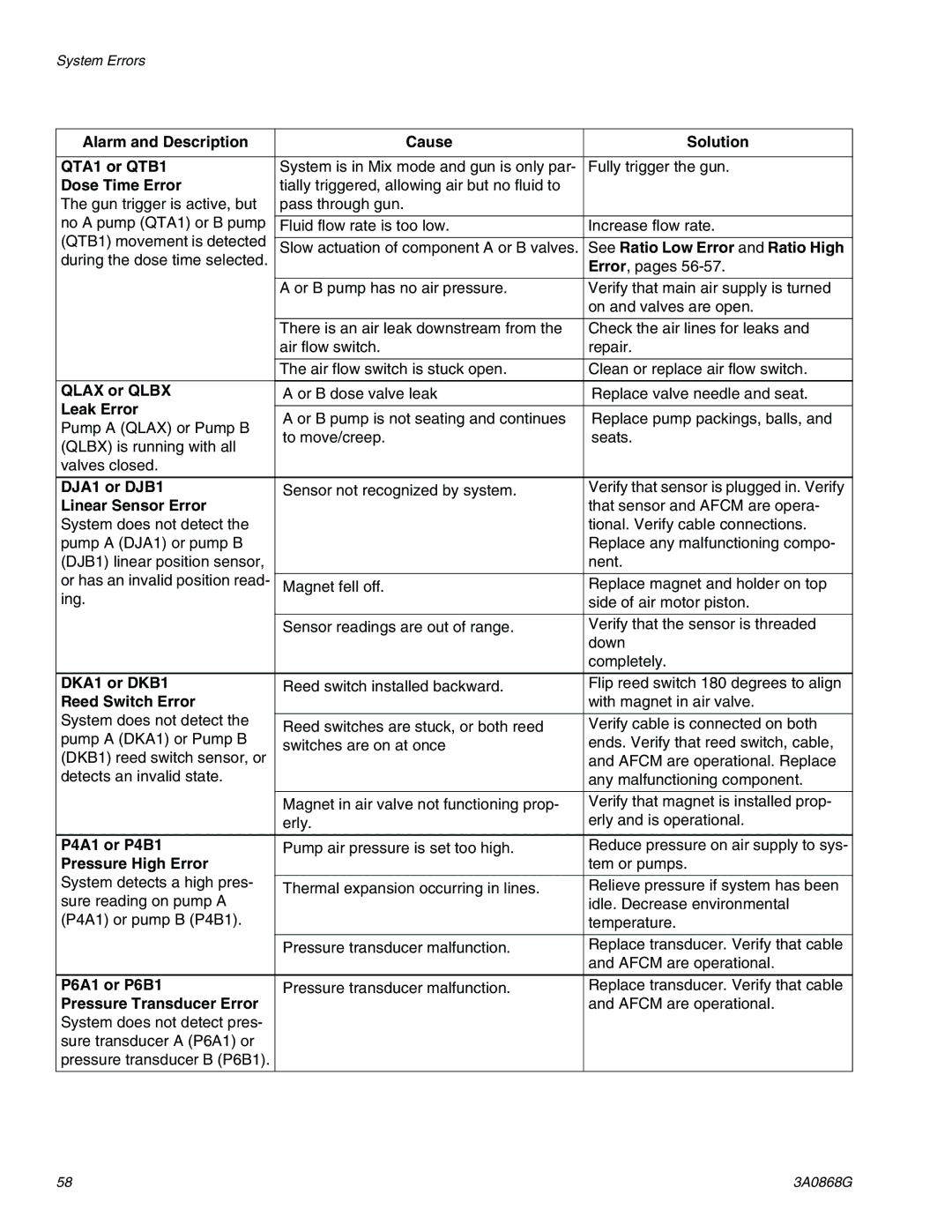

System Errors

Alarm and Description | Cause | Solution | |

|

|

| |

QTA1 or QTB1 | System is in Mix mode and gun is only par- | Fully trigger the gun. | |

Dose Time Error | tially triggered, allowing air but no fluid to |

| |

The gun trigger is active, but | pass through gun. |

| |

no A pump (QTA1) or B pump |

|

| |

Fluid flow rate is too low. | Increase flow rate. | ||

(QTB1) movement is detected |

|

| |

Slow actuation of component A or B valves. | See Ratio Low Error and Ratio High | ||

during the dose time selected. |

| Error, pages | |

|

| ||

|

|

| |

| A or B pump has no air pressure. | Verify that main air supply is turned | |

|

| on and valves are open. | |

|

|

| |

| There is an air leak downstream from the | Check the air lines for leaks and | |

| air flow switch. | repair. | |

|

|

| |

| The air flow switch is stuck open. | Clean or replace air flow switch. | |

|

|

| |

QLAX or QLBX | A or B dose valve leak | Replace valve needle and seat. | |

Leak Error |

|

| |

A or B pump is not seating and continues | Replace pump packings, balls, and | ||

Pump A (QLAX) or Pump B | |||

to move/creep. | seats. | ||

(QLBX) is running with all | |||

|

| ||

valves closed. |

|

| |

|

|

| |

DJA1 or DJB1 | Sensor not recognized by system. | Verify that sensor is plugged in. Verify | |

Linear Sensor Error |

| that sensor and AFCM are opera- | |

System does not detect the |

| tional. Verify cable connections. | |

pump A (DJA1) or pump B |

| Replace any malfunctioning compo- | |

(DJB1) linear position sensor, |

| nent. | |

or has an invalid position read- |

|

| |

Magnet fell off. | Replace magnet and holder on top | ||

ing. |

| side of air motor piston. | |

|

|

| |

| Sensor readings are out of range. | Verify that the sensor is threaded | |

|

| down | |

|

| completely. | |

|

|

| |

DKA1 or DKB1 | Reed switch installed backward. | Flip reed switch 180 degrees to align | |

Reed Switch Error |

| with magnet in air valve. | |

System does not detect the |

|

| |

Reed switches are stuck, or both reed | Verify cable is connected on both | ||

pump A (DKA1) or Pump B | switches are on at once | ends. Verify that reed switch, cable, | |

(DKB1) reed switch sensor, or |

| and AFCM are operational. Replace | |

detects an invalid state. |

| any malfunctioning component. | |

|

|

| |

| Magnet in air valve not functioning prop- | Verify that magnet is installed prop- | |

| erly. | erly and is operational. | |

|

|

| |

P4A1 or P4B1 | Pump air pressure is set too high. | Reduce pressure on air supply to sys- | |

Pressure High Error |

| tem or pumps. | |

System detects a high pres- |

|

| |

Thermal expansion occurring in lines. | Relieve pressure if system has been | ||

sure reading on pump A |

| idle. Decrease environmental | |

(P4A1) or pump B (P4B1). |

| temperature. | |

|

|

| |

| Pressure transducer malfunction. | Replace transducer. Verify that cable | |

|

| and AFCM are operational. | |

P6A1 or P6B1 | Pressure transducer malfunction. | Replace transducer. Verify that cable | |

Pressure Transducer Error |

| and AFCM are operational. | |

System does not detect pres- |

|

| |

sure transducer A (P6A1) or |

|

| |

pressure transducer B (P6B1). |

|

| |

|

|

|

58 | 3A0868G |