5:3

Camera body 503CW | Adjustment |

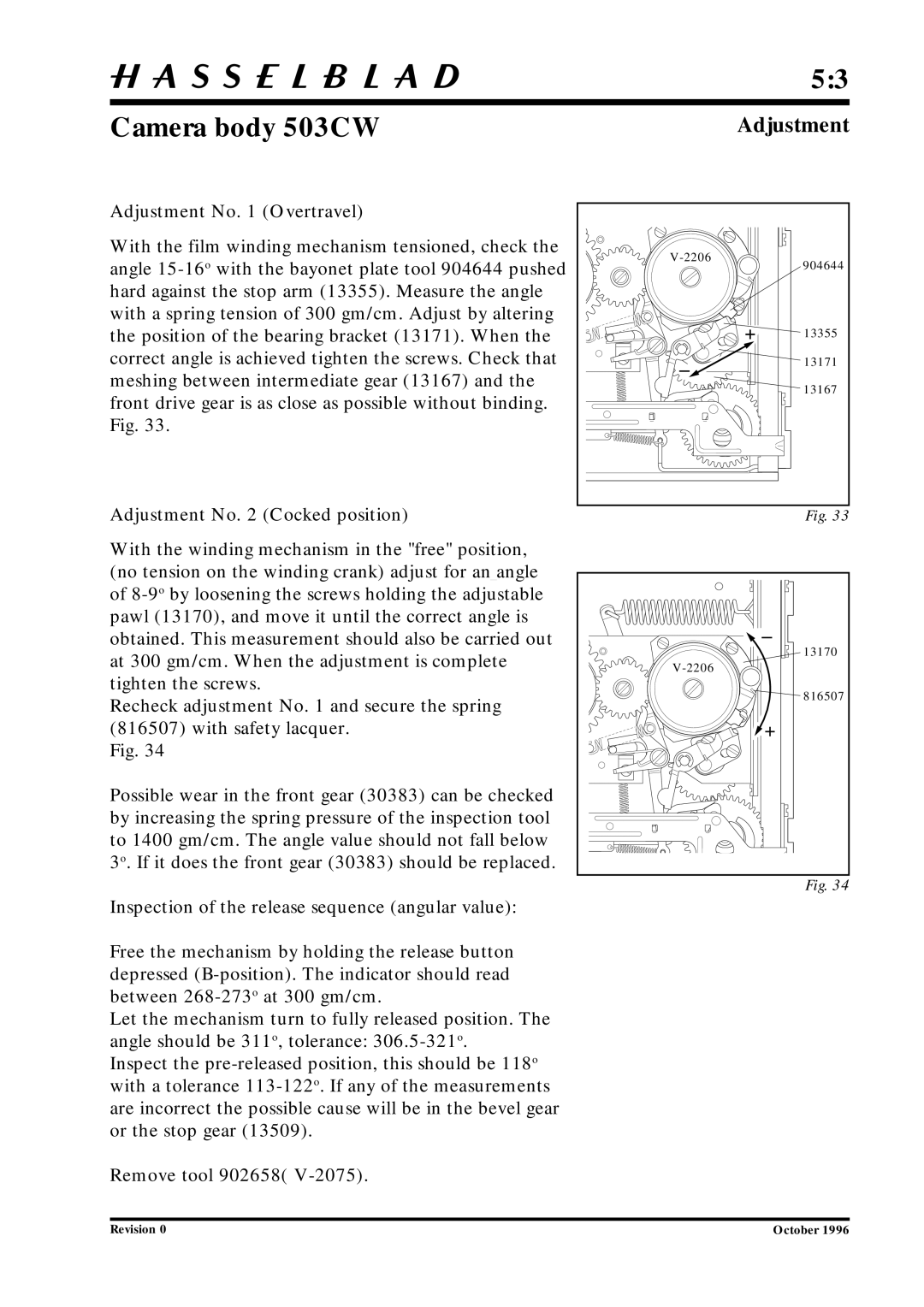

Adjustment No. 1 (Overtravel) |

|

| |

With the film winding mechanism tensioned, check the |

| ||

angle | 904644 | ||

| |||

hard against the stop arm (13355). Measure the angle |

|

| |

with a spring tension of 300 gm/cm. Adjust by altering |

|

| |

the position of the bearing bracket (13171). When the |

| 13355 | |

correct angle is achieved tighten the screws. Check that |

| 13171 | |

meshing between intermediate gear (13167) and the |

| 13167 | |

front drive gear is as close as possible without binding. |

| ||

|

| ||

Fig. 33. |

|

| |

Adjustment No. 2 (Cocked position) |

| Fig. 33 | |

With the winding mechanism in the "free" position, |

|

| |

(no tension on the winding crank) adjust for an angle |

|

| |

of |

|

| |

pawl (13170), and move it until the correct angle is |

|

| |

obtained. This measurement should also be carried out |

| 13170 | |

at 300 gm/cm. When the adjustment is complete |

| ||

| |||

tighten the screws. |

| 816507 | |

Recheck adjustment No. 1 and secure the spring |

| ||

|

| ||

(816507) with safety lacquer. |

|

| |

Fig. 34 |

|

|

Possible wear in the front gear (30383) can be checked by increasing the spring pressure of the inspection tool to 1400 gm/cm. The angle value should not fall below 3o. If it does the front gear (30383) should be replaced.

Fig. 34

Inspection of the release sequence (angular value):

Free the mechanism by holding the release button depressed

Let the mechanism turn to fully released position. The angle should be 311o, tolerance:

Inspect the

Remove tool 902658(

Revision 0 | October 1996 |