7.0 INSTALLATION

Water quality recommendations

Water quality recommendations Water quality is often overlooked when the cooling system of a water−cooled air compressor is examined. Water quality determines how effective the heat transfer rate, as well as the flow rate will remain during the life of the unit. It should

be noted that the quality of water used in any cooling system does not remain constant during the operation of the system. Evaporation, corrosion, chemical and temperature changes, aeration, scale and biological formations effect the water makeup. Most problems in a cooling system show up first in a reduction in the heat transfer rate, then in a reduced flow rate and finally with damage to the system.

Scale: Scale formation inhibits effective heat transfer, yet it does help prevent corrosion. Therefore, a thin uniform coating of calcium carbonate is desired on the inner surface. Perhaps the largest contributor to scale formation is the precipitation of calcium carbonate out of the water. This is dependent on temperature and pH. The higher the pH value, the greater the chance of scale formation. Scale can be controlled with water treatment.

Corrosion: In contrast to scale formation is the problem of corrosion. Chlorides cause problems because of their size and conductivity. Low pH levels promote corrosion, as well as high levels of dissolved oxygen.

Fouling: Biological and organic substances (slime) can also cause problems, but in elevated temperature environments such as cooling processes they are not a major concern. If they create problems with clogging, commercial shock treatment are available.

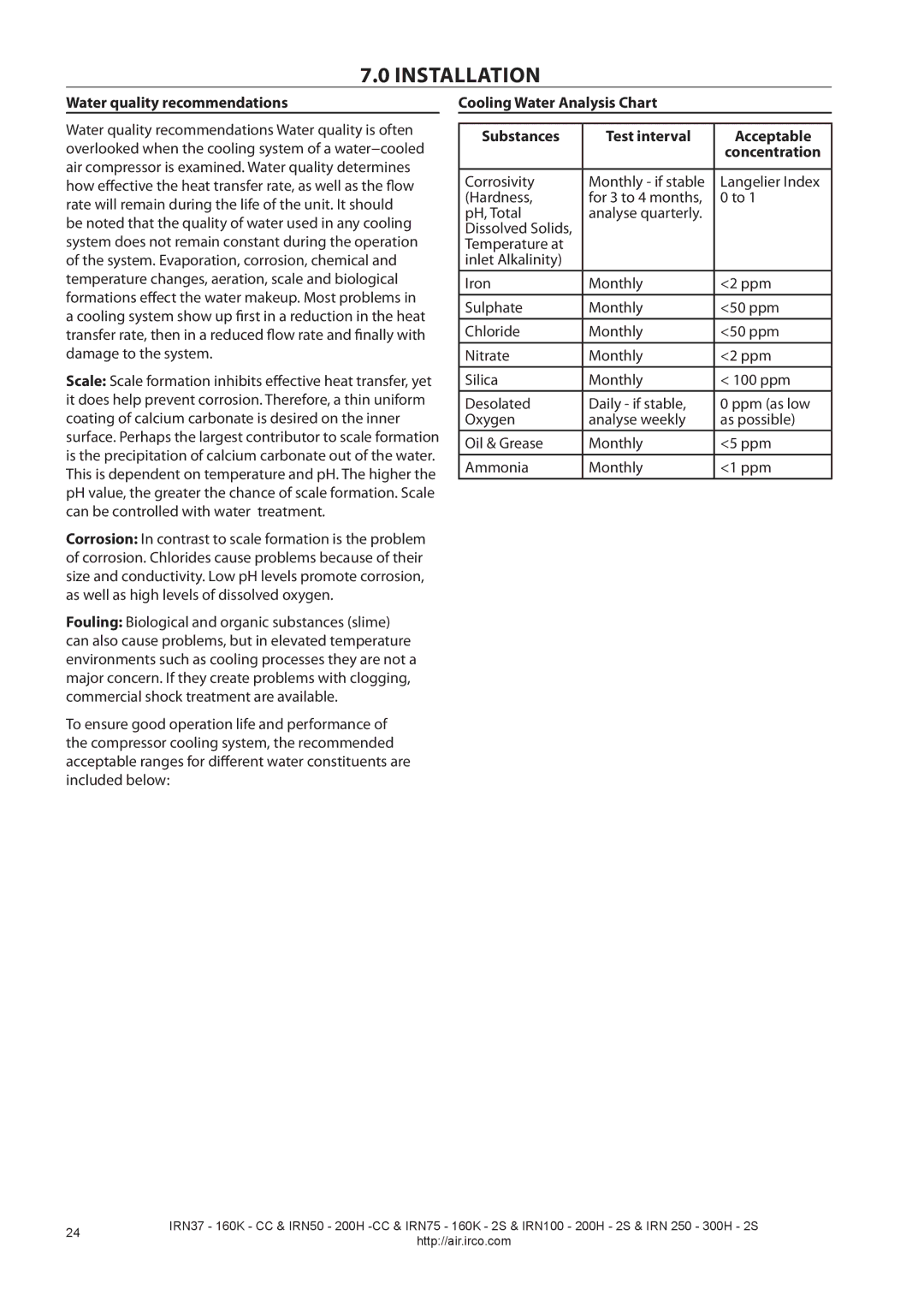

To ensure good operation life and performance of the compressor cooling system, the recommended acceptable ranges for different water constituents are included below:

Cooling Water Analysis Chart

Substances | Test interval | Acceptable |

|

| concentration |

|

|

|

Corrosivity | Monthly - if stable | Langelier Index |

(Hardness, | for 3 to 4 months, | 0 to 1 |

pH, Total | analyse quarterly. |

|

Dissolved Solids, |

|

|

Temperature at |

|

|

inlet Alkalinity) |

|

|

Iron | Monthly | <2 ppm |

Sulphate | Monthly | <50 ppm |

|

|

|

Chloride | Monthly | <50 ppm |

Nitrate | Monthly | <2 ppm |

Silica | Monthly | < 100 ppm |

|

|

|

Desolated | Daily - if stable, | 0 ppm (as low |

Oxygen | analyse weekly | as possible) |

Oil & Grease | Monthly | <5 ppm |

Ammonia | Monthly | <1 ppm |

24IRN37 - 160K - CC & IRN50 - 200H

http://air.irco.com