2.0 fOREWORD

![]()

![]() warning

warning

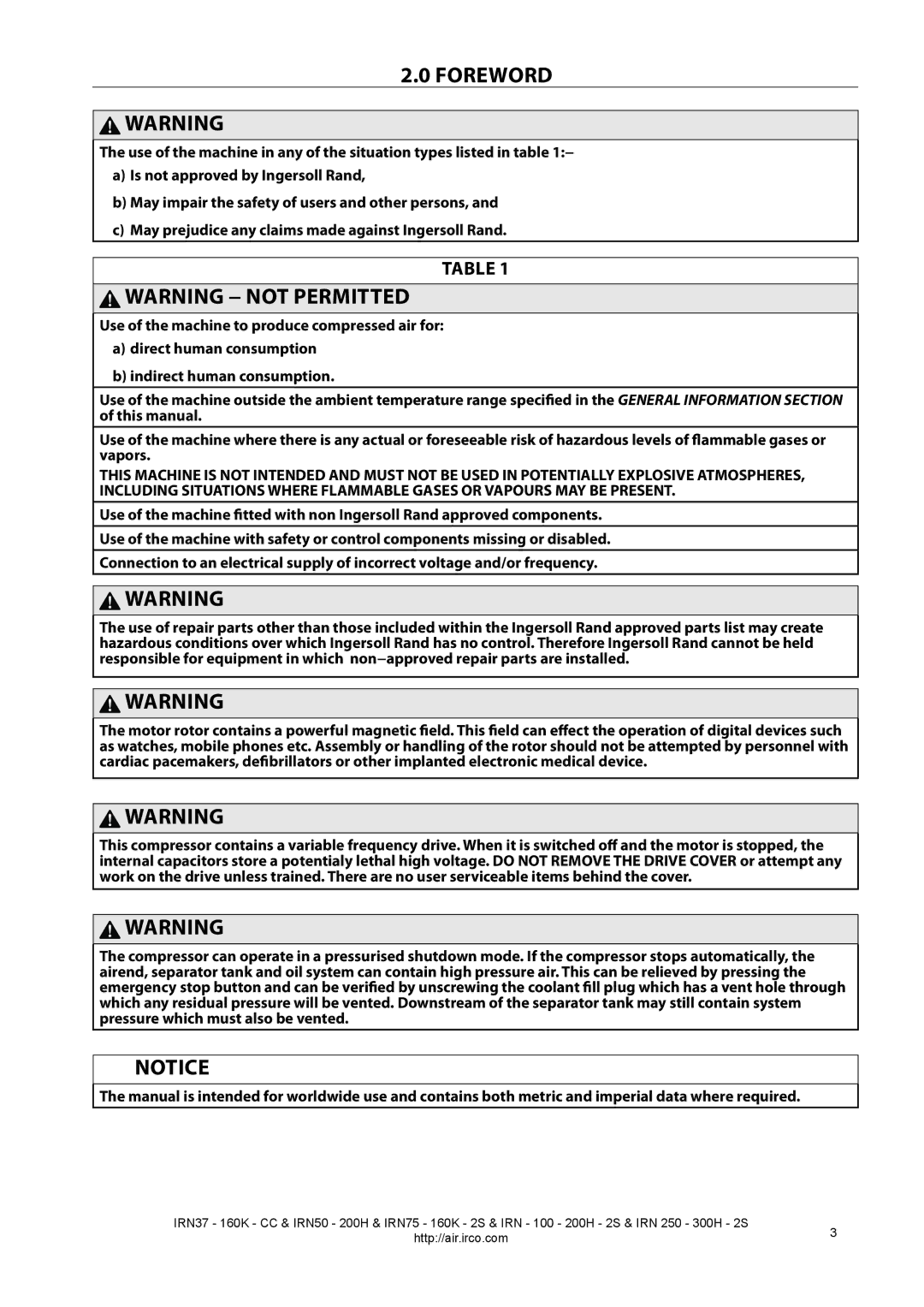

The use of the machine in any of the situation types listed in table 1:−

a)Is not approved by Ingersoll Rand,

b)May impair the safety of users and other persons, and

c)May prejudice any claims made against Ingersoll Rand.

TABLE 1

![]() warning − NOT PERMITTED

warning − NOT PERMITTED

Use of the machine to produce compressed air for:

a)direct human consumption

b)indirect human consumption.

Use of the machine outside the ambient temperature range specified in the GENERAL INFORMATION SECTION of this manual.

Use of the machine where there is any actual or foreseeable risk of hazardous levels of flammable gases or vapors.

THIS MACHINE IS NOT INTENDED AND MUST NOT BE USED IN POTENTIALLY EXPLOSIVE ATMOSPHERES, INCLUDING SITUATIONS WHERE FLAMMABLE GASES OR VAPOURS MAY BE PRESENT.

Use of the machine fitted with non Ingersoll Rand approved components.

Use of the machine with safety or control components missing or disabled.

Connection to an electrical supply of incorrect voltage and/or frequency.

![]()

![]() warning

warning

The use of repair parts other than those included within the Ingersoll Rand approved parts list may create hazardous conditions over which Ingersoll Rand has no control. Therefore Ingersoll Rand cannot be held responsible for equipment in which non−approved repair parts are installed.

![]()

![]() warning

warning

The motor rotor contains a powerful magnetic field. This field can effect the operation of digital devices such as watches, mobile phones etc. Assembly or handling of the rotor should not be attempted by personnel with cardiac pacemakers, defibrillators or other implanted electronic medical device.

![]()

![]() warning

warning

This compressor contains a variable frequency drive. When it is switched off and the motor is stopped, the internal capacitors store a potentialy lethal high voltage. DO NOT REMOVE THE DRIVE COVER or attempt any work on the drive unless trained. There are no user serviceable items behind the cover.

![]()

![]() warning

warning

The compressor can operate in a pressurised shutdown mode. If the compressor stops automatically, the airend, separator tank and oil system can contain high pressure air. This can be relieved by pressing the emergency stop button and can be verified by unscrewing the coolant fill plug which has a vent hole through which any residual pressure will be vented. Downstream of the separator tank may still contain system pressure which must also be vented.

notice

The manual is intended for worldwide use and contains both metric and imperial data where required.

IRN37 - 160K - CC & IRN50 - 200H & IRN75 - 160K - 2S & IRN - 100 - 200H - 2S & IRN 250 - 300H - 2S

http://air.irco.com