5.0 SAFETY

5.1 SAFETY INSTRUCTIONS

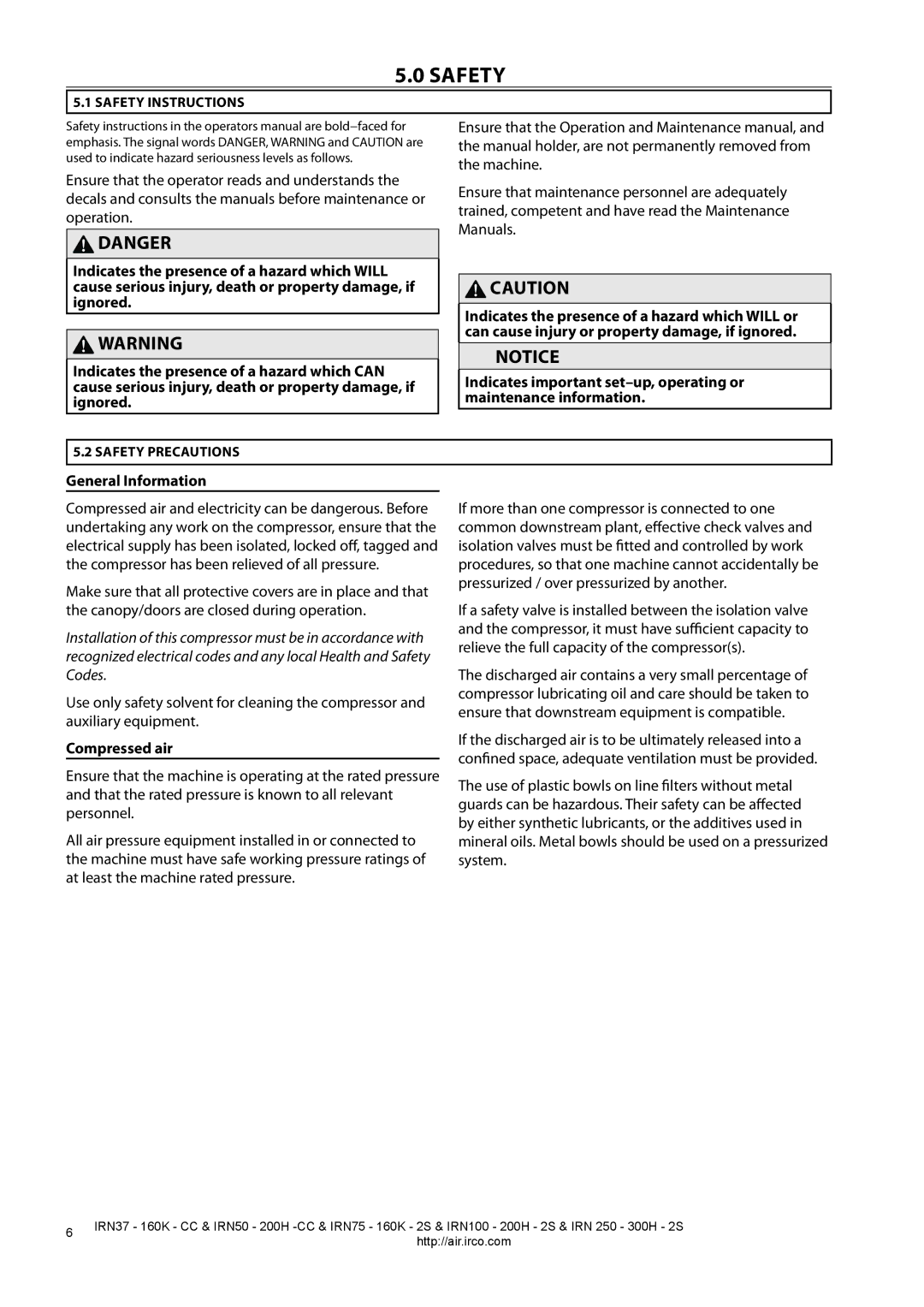

Safety instructions in the operators manual are bold−faced for emphasis. The signal words DANGER, WARNING and CAUTION are used to indicate hazard seriousness levels as follows.

Ensure that the operator reads and understands the decals and consults the manuals before maintenance or operation.

![]()

![]() danger

danger

Indicates the presence of a hazard which WILL cause serious injury, death or property damage, if ignored.

![]()

![]() warning

warning

Indicates the presence of a hazard which CAN cause serious injury, death or property damage, if ignored.

Ensure that the Operation and Maintenance manual, and the manual holder, are not permanently removed from the machine.

Ensure that maintenance personnel are adequately trained, competent and have read the Maintenance Manuals.

![]()

![]() caution

caution

Indicates the presence of a hazard which WILL or can cause injury or property damage, if ignored.

NOTICE

Indicates important

5.2 SAFETY PRECAUTIONS

General Information

Compressed air and electricity can be dangerous. Before undertaking any work on the compressor, ensure that the electrical supply has been isolated, locked off, tagged and the compressor has been relieved of all pressure.

Make sure that all protective covers are in place and that the canopy/doors are closed during operation.

Installation of this compressor must be in accordance with recognized electrical codes and any local Health and Safety Codes.

Use only safety solvent for cleaning the compressor and auxiliary equipment.

Compressed air

Ensure that the machine is operating at the rated pressure and that the rated pressure is known to all relevant personnel.

All air pressure equipment installed in or connected to the machine must have safe working pressure ratings of at least the machine rated pressure.

If more than one compressor is connected to one common downstream plant, effective check valves and isolation valves must be fitted and controlled by work procedures, so that one machine cannot accidentally be pressurized / over pressurized by another.

If a safety valve is installed between the isolation valve and the compressor, it must have sufficient capacity to relieve the full capacity of the compressor(s).

The discharged air contains a very small percentage of compressor lubricating oil and care should be taken to ensure that downstream equipment is compatible.

If the discharged air is to be ultimately released into a confined space, adequate ventilation must be provided.

The use of plastic bowls on line filters without metal guards can be hazardous. Their safety can be affected by either synthetic lubricants, or the additives used in mineral oils. Metal bowls should be used on a pressurized system.

IRN37 - 160K - CC & IRN50 - 200H