7.0 INSTALLATION

7.2 DISCHARGE AND CONDENSATE PIPING

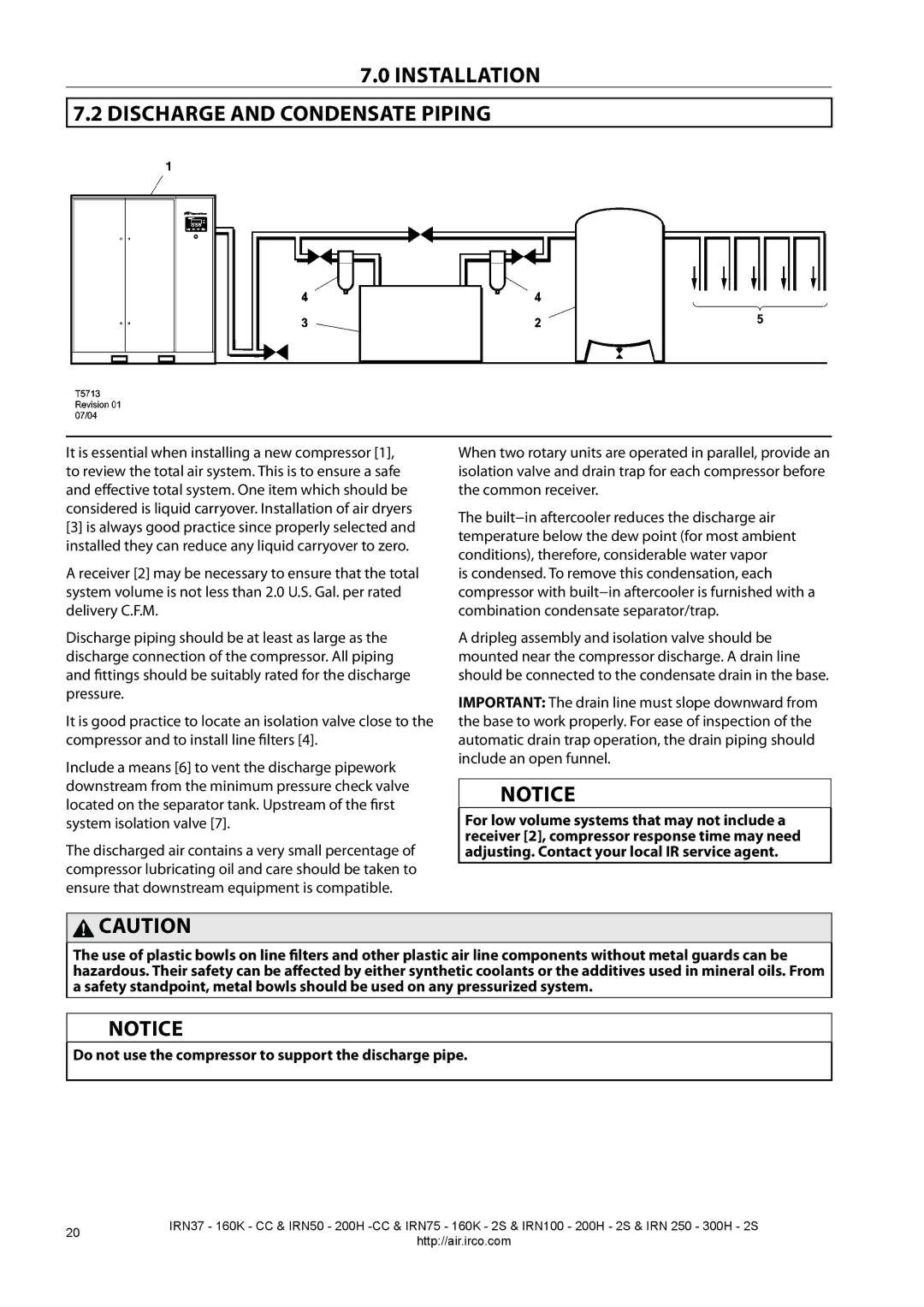

It is essential when installing a new compressor [1], to review the total air system. This is to ensure a safe and effective total system. One item which should be considered is liquid carryover. Installation of air dryers

[3]is always good practice since properly selected and installed they can reduce any liquid carryover to zero.

A receiver [2] may be necessary to ensure that the total system volume is not less than 2.0 U.S. Gal. per rated delivery C.F.M.

Discharge piping should be at least as large as the discharge connection of the compressor. All piping and fittings should be suitably rated for the discharge pressure.

It is good practice to locate an isolation valve close to the compressor and to install line filters [4].

Include a means [6] to vent the discharge pipework downstream from the minimum pressure check valve located on the separator tank. Upstream of the first system isolation valve [7].

The discharged air contains a very small percentage of compressor lubricating oil and care should be taken to ensure that downstream equipment is compatible.

When two rotary units are operated in parallel, provide an isolation vaIve and drain trap for each compressor before the common receiver.

The built−in aftercooler reduces the discharge air temperature below the dew point (for most ambient conditions), therefore, considerable water vapor

is condensed. To remove this condensation, each compressor with built−in aftercooler is furnished with a combination condensate separator/trap.

A dripleg assembly and isolation valve should be mounted near the compressor discharge. A drain line should be connected to the condensate drain in the base.

IMPORTANT: The drain line must slope downward from the base to work properly. For ease of inspection of the automatic drain trap operation, the drain piping should include an open funnel.

NOTICE

For low volume systems that may not include a receiver [2], compressor response time may need adjusting. Contact your local IR service agent.

![]()

![]() caution

caution

The use of plastic bowls on line filters and other plastic air line components without metal guards can be hazardous. Their safety can be affected by either synthetic coolants or the additives used in mineral oils. From a safety standpoint, metal bowls should be used on any pressurized system.

NOTICE

Do not use the compressor to support the discharge pipe.

20IRN37 - 160K - CC & IRN50 - 200H

http://air.irco.com