9.0 OPERATING INSTRUCTIONS

9.15 ALARMS

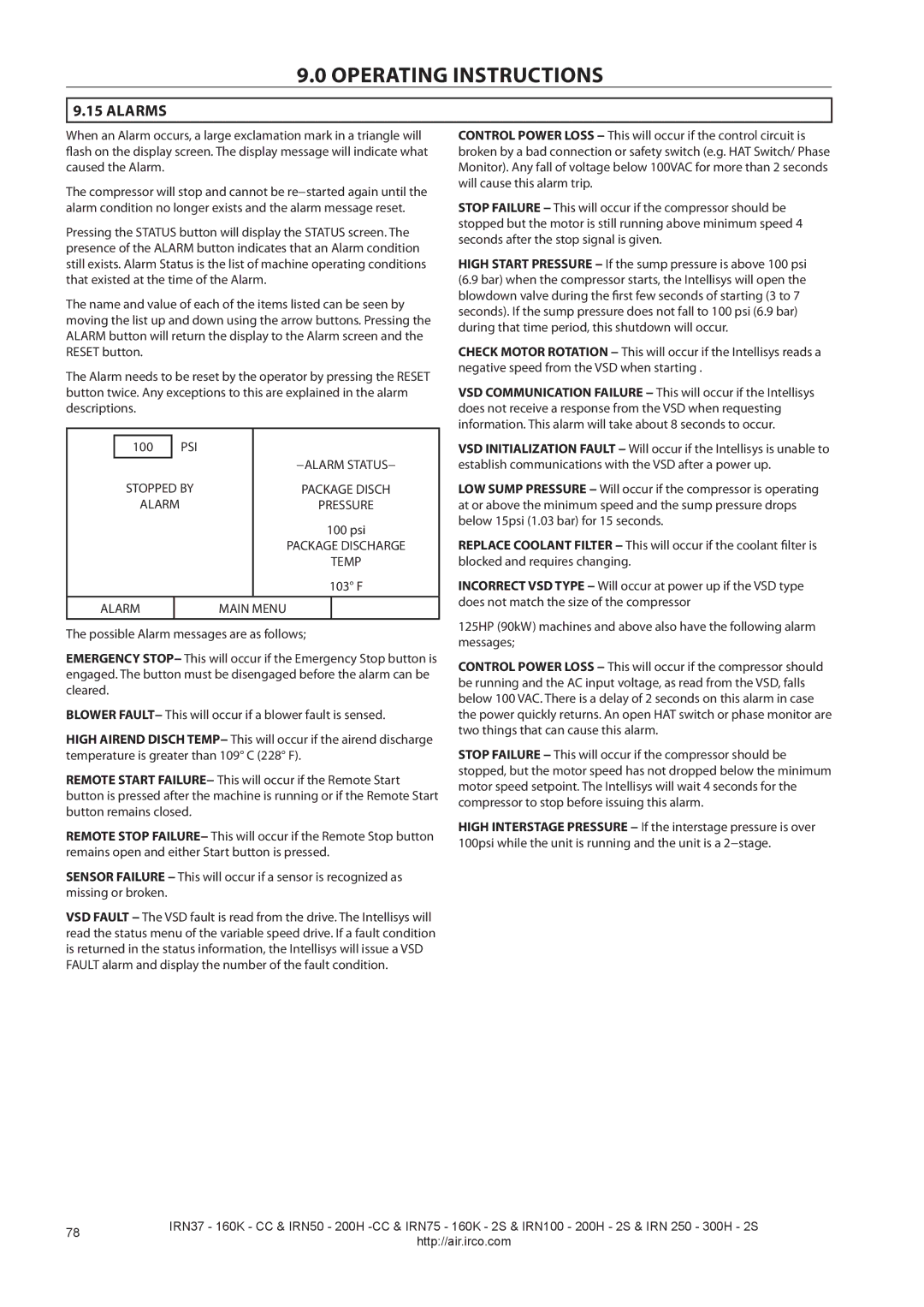

When an Alarm occurs, a large exclamation mark in a triangle will flash on the display screen. The display message will indicate what caused the Alarm.

The compressor will stop and cannot be re−started again until the alarm condition no longer exists and the alarm message reset.

Pressing the STATUS button will display the STATUS screen. The presence of the ALARM button indicates that an Alarm condition still exists. Alarm Status is the list of machine operating conditions that existed at the time of the Alarm.

The name and value of each of the items listed can be seen by moving the list up and down using the arrow buttons. Pressing the ALARM button will return the display to the Alarm screen and the RESET button.

The Alarm needs to be reset by the operator by pressing the RESET button twice. Any exceptions to this are explained in the alarm descriptions.

|

|

|

|

|

|

|

| 100 |

| PSI |

|

|

|

|

|

|

|

| −ALARM STATUS− | |

| STOPPED BY |

| ||||

|

| PACKAGE DISCH | ||||

| ALARM |

|

| PRESSURE | ||

|

|

|

|

| 100 psi | |

|

|

|

|

| PACKAGE DISCHARGE | |

|

|

|

|

|

| TEMP |

|

|

|

|

| 103° F | |

|

|

|

|

|

|

|

ALARM |

|

| MAIN MENU |

| ||

The possible Alarm messages are as follows;

EMERGENCY STOP− This will occur if the Emergency Stop button is engaged. The button must be disengaged before the alarm can be cleared.

BLOWER FAULT− This will occur if a blower fault is sensed.

HIGH AIREND DISCH TEMP− This will occur if the airend discharge temperature is greater than 109° C (228° F).

REMOTE START FAILURE− This will occur if the Remote Start button is pressed after the machine is running or if the Remote Start button remains closed.

REMOTE STOP FAILURE− This will occur if the Remote Stop button remains open and either Start button is pressed.

SENSOR FAILURE − This will occur if a sensor is recognized as missing or broken.

VSD FAULT − The VSD fault is read from the drive. The Intellisys will read the status menu of the variable speed drive. If a fault condition is returned in the status information, the Intellisys will issue a VSD FAULT alarm and display the number of the fault condition.

CONTROL POWER LOSS − This will occur if the control circuit is broken by a bad connection or safety switch (e.g. HAT Switch/ Phase Monitor). Any fall of voltage below 100VAC for more than 2 seconds will cause this alarm trip.

STOP FAILURE − This will occur if the compressor should be stopped but the motor is still running above minimum speed 4 seconds after the stop signal is given.

HIGH START PRESSURE − If the sump pressure is above 100 psi (6.9 bar) when the compressor starts, the Intellisys will open the blowdown valve during the first few seconds of starting (3 to 7 seconds). If the sump pressure does not fall to 100 psi (6.9 bar) during that time period, this shutdown will occur.

CHECK MOTOR ROTATION − This will occur if the Intellisys reads a negative speed from the VSD when starting .

VSD COMMUNICATION FAILURE − This will occur if the Intellisys does not receive a response from the VSD when requesting information. This alarm will take about 8 seconds to occur.

VSD INITIALIZATION FAULT − Will occur if the Intellisys is unable to establish communications with the VSD after a power up.

LOW SUMP PRESSURE − Will occur if the compressor is operating at or above the minimum speed and the sump pressure drops below 15psi (1.03 bar) for 15 seconds.

REPLACE COOLANT FILTER − This will occur if the coolant filter is blocked and requires changing.

INCORRECT VSD TYPE − Will occur at power up if the VSD type does not match the size of the compressor

125HP (90kW) machines and above also have the following alarm messages;

CONTROL POWER LOSS − This will occur if the compressor should be running and the AC input voltage, as read from the VSD, falls below 100 VAC. There is a delay of 2 seconds on this alarm in case the power quickly returns. An open HAT switch or phase monitor are two things that can cause this alarm.

STOP FAILURE − This will occur if the compressor should be stopped, but the motor speed has not dropped below the minimum motor speed setpoint. The Intellisys will wait 4 seconds for the compressor to stop before issuing this alarm.

HIGH INTERSTAGE PRESSURE − If the interstage pressure is over 100psi while the unit is running and the unit is a 2−stage.

78IRN37 - 160K - CC & IRN50 - 200H

http://air.irco.com