Return to Section TOC

Return to Master TOC

| OPERATION | ||||

|

|

|

| ||

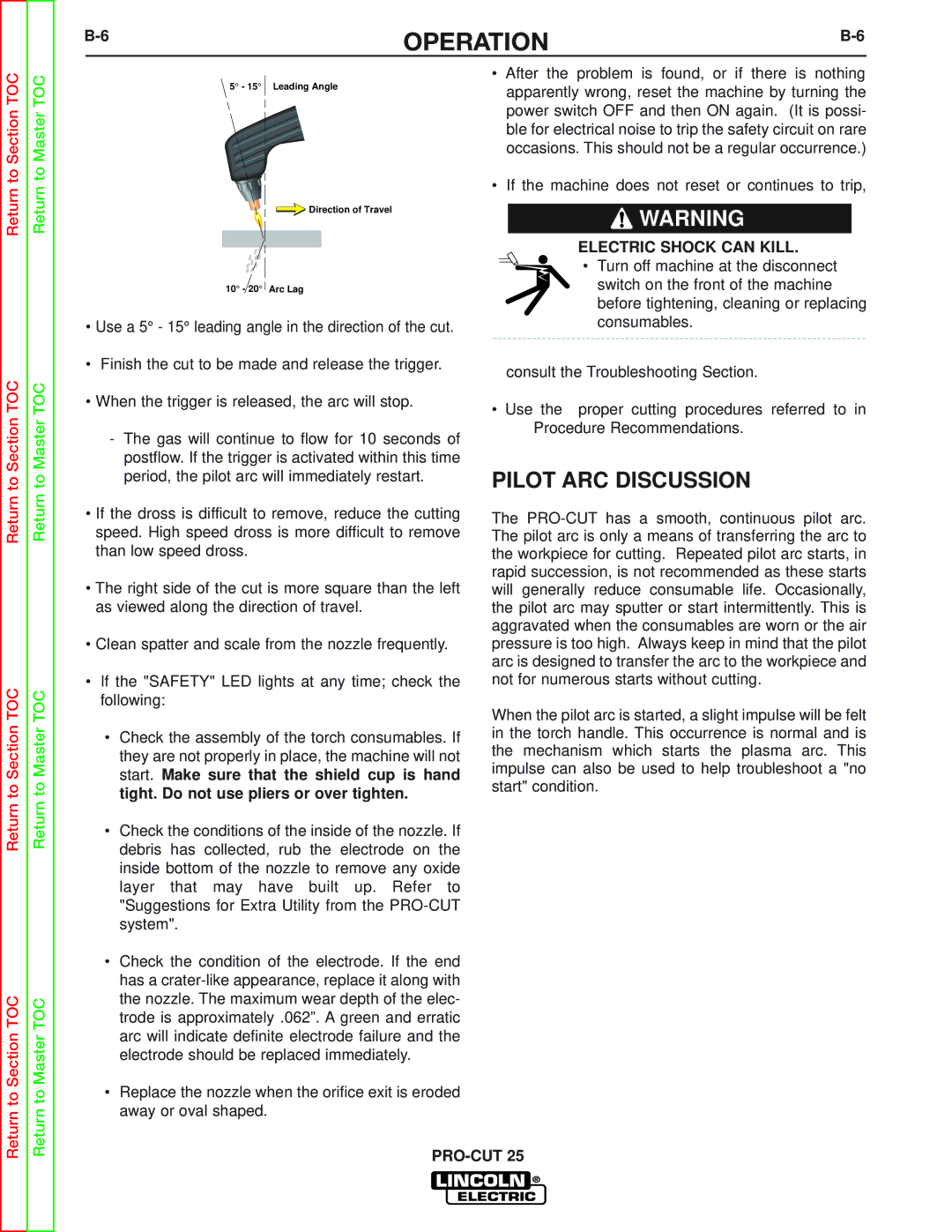

5° - 15° | Leading Angle | • After the problem is found, or if there is nothing | |||

apparently wrong, reset the machine by turning the | |||||

|

|

| |||

power switch OFF and then ON again. (It is possi- ble for electrical noise to trip the safety circuit on rare occasions. This should not be a regular occurrence.)

• If the machine does not reset or continues to trip,

Direction of Travel | WARNING |

|

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

10° - 20° Arc Lag

•Use a 5° - 15° leading angle in the direction of the cut.

•Finish the cut to be made and release the trigger.

•When the trigger is released, the arc will stop.

-The gas will continue to flow for 10 seconds of postflow. If the trigger is activated within this time period, the pilot arc will immediately restart.

•If the dross is difficult to remove, reduce the cutting speed. High speed dross is more difficult to remove than low speed dross.

•The right side of the cut is more square than the left as viewed along the direction of travel.

•Clean spatter and scale from the nozzle frequently.

•If the "SAFETY" LED lights at any time; check the following:

•Check the assembly of the torch consumables. If they are not properly in place, the machine will not start. Make sure that the shield cup is hand tight. Do not use pliers or over tighten.

•Check the conditions of the inside of the nozzle. If debris has collected, rub the electrode on the inside bottom of the nozzle to remove any oxide layer that may have built up. Refer to "Suggestions for Extra Utility from the

•Check the condition of the electrode. If the end has a

•Replace the nozzle when the orifice exit is eroded away or oval shaped.

ELECTRIC SHOCK CAN KILL.

• Turn off machine at the disconnect switch on the front of the machine before tightening, cleaning or replacing

consumables.

consult the Troubleshooting Section.

•Use the proper cutting procedures referred to in Procedure Recommendations.

PILOT ARC DISCUSSION

The

When the pilot arc is started, a slight impulse will be felt in the torch handle. This occurrence is normal and is the mechanism which starts the plasma arc. This impulse can also be used to help troubleshoot a "no start" condition.