Section TOC

Master TOC

THEORY OF OPERATION

FIGURE E.4 – MAIN TRANSFORMER

INPUT 115/230/1/50/60 VAC

L1 SW1 A 300uH

B |

RL3 |

| RL2 |

R1 |

| RL2 |

10/10W |

| |

F1 |

| |

1A/250V | RL2 | |

|

|

C26

AC | AC |

| |

CP | CP | CP | |

CP | CP | ||

| |||

AC | AC |

|

R1 ![]()

![]()

CP

R2 ![]()

![]()

15K/3W 15K/3W

1500uF/250V

+

C1a,b

+

C2a,b

Q1a,b,c | D10 | Lout | BS1 |

|

IRG4BC30W | WRK | |||

|

| 240uH | 8A |

|

|

|

|

| |

T2 | SEC |

| +12VDC TRANSFER |

|

PRI |

|

|

| |

C12 | D11 |

| RL1 | NZL (2) |

|

|

|

| |

|

|

| C14 |

|

WORK CLAMP

V1 |

RL2

RL1

| R24 |

Q2a,b,c | 6.8k/5W |

IRG4BC30W |

|

FN1 | 230VAC | V2 |

|

|

115VAC

L1

T1

230V

RL1

1500uF/250V

| SHUNT | EL (3) | |

C13 | SH- | SH+ |

|

|

| ||

Return to Section TOC

Return to Master TOC

NO | COM | NC |

Purge Switch

115V

L1

Input

Voltage Board

12VDC

Air

Solenoid

1

CN1 | 15VAC |

| CN2 |

|

|

|

|

|

|

|

|

|

|

|

| CN3 | ||

1 |

| 9 |

|

|

|

|

|

|

|

|

|

|

|

| 1 | |||

2 | 15VAC |

| 10 |

|

|

|

|

|

|

|

|

|

|

|

| 2 | ||

3 | SAFETY |

| 5 |

|

|

|

|

|

|

|

|

|

|

|

| 3 | ||

4 | +28VDC |

| 6 |

|

|

|

|

|

|

|

|

|

|

|

| 4 | ||

5 | SEC GND |

| 3 |

|

|

|

|

|

|

|

|

|

|

|

| Main Inverter Board | ||

6 | OVLOAD |

| 22 |

|

|

|

|

|

|

|

|

|

|

|

| |||

7 | 115/230 |

| 2 |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

8 | +12VDC |

| 20 |

|

|

|

|

|

|

|

|

| CN1 |

|

|

| ||

|

|

|

|

| 15 16 12 18 14 1 |

|

|

|

|

|

|

|

|

| 4 | |||

|

|

|

|

| 11 4 | 13 7 | 19 24 21 23 8 | 17 | 1 | 2 | 3 | |||||||

| PS2 | PS1 | SEC GND OVLOAD | SAFETY | V+ EV1 +15Vrms | +12VDC | +8V SW +12VDC SW | SEC GND | OVLOAD | TRANSFER SW | TRANSFER | SOL 1 DRIVER | V OUT OUTPUT TRIGGER SOL 2 DRIVER |

| POT WIPER | POT CW | POT CCW |

|

CN1 | 8 | 6 | 17 9 | 3 | 1 | 2 | 18 14 7 | 15 4 | 11 5 | 16 10 12 13 |

| 23 22 24 |

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Display LED's

Output Control

Control Board

PT

12VDC Solenoid 2

to Section TOC

to Master TOC

MAIN TRANSFORMER

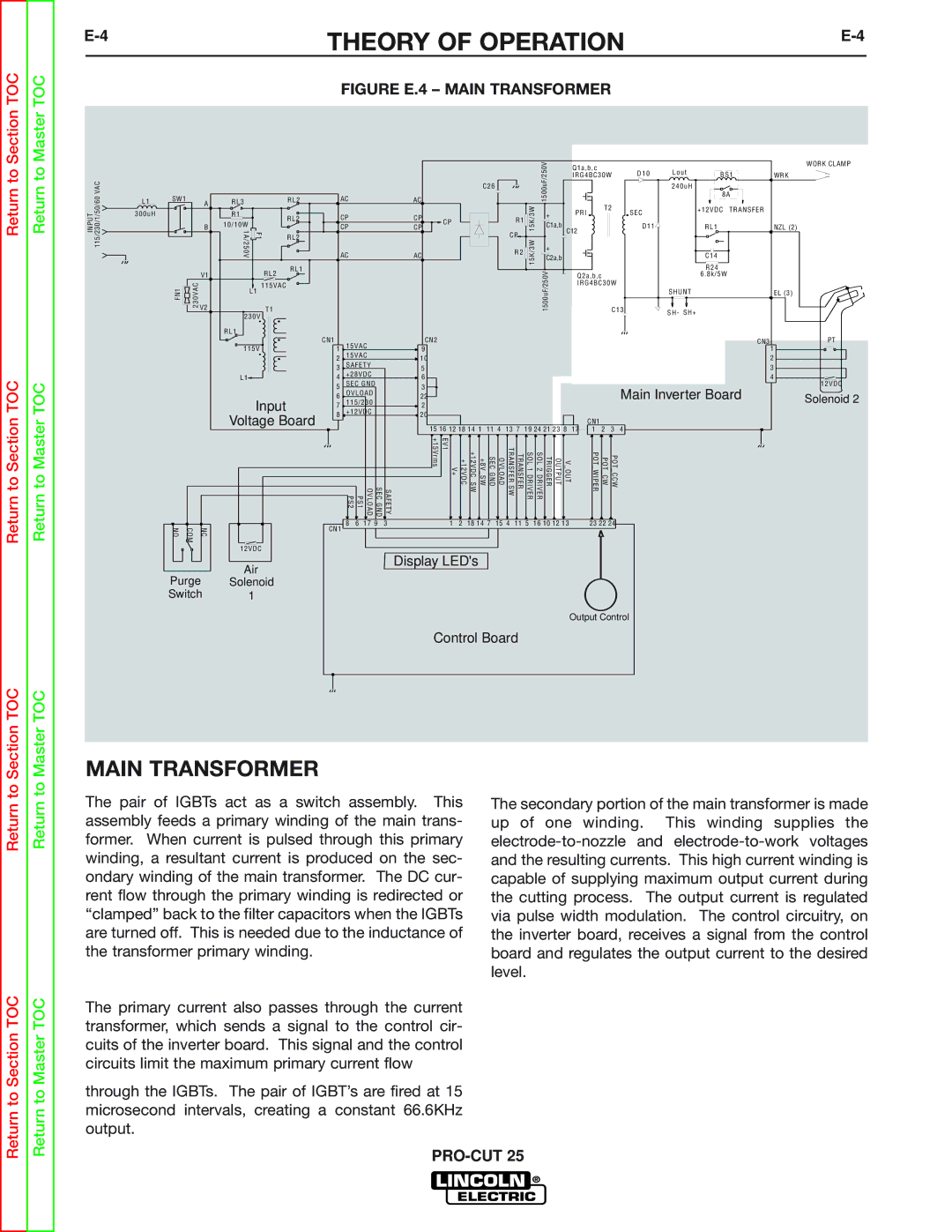

The pair of IGBTs act as a switch assembly. This assembly feeds a primary winding of the main trans- former. When current is pulsed through this primary winding, a resultant current is produced on the sec- ondary winding of the main transformer. The DC cur- rent flow through the primary winding is redirected or “clamped” back to the filter capacitors when the IGBTs are turned off. This is needed due to the inductance of the transformer primary winding.

The primary current also passes through the current transformer, which sends a signal to the control cir- cuits of the inverter board. This signal and the control circuits limit the maximum primary current flow

through the IGBTs. The pair of IGBT’s are fired at 15 microsecond intervals, creating a constant 66.6KHz output.

The secondary portion of the main transformer is made up of one winding. This winding supplies the