Return to Section TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR |

MAIN INVERTER BOARD REMOVAL & REPLACEMENT (continued)

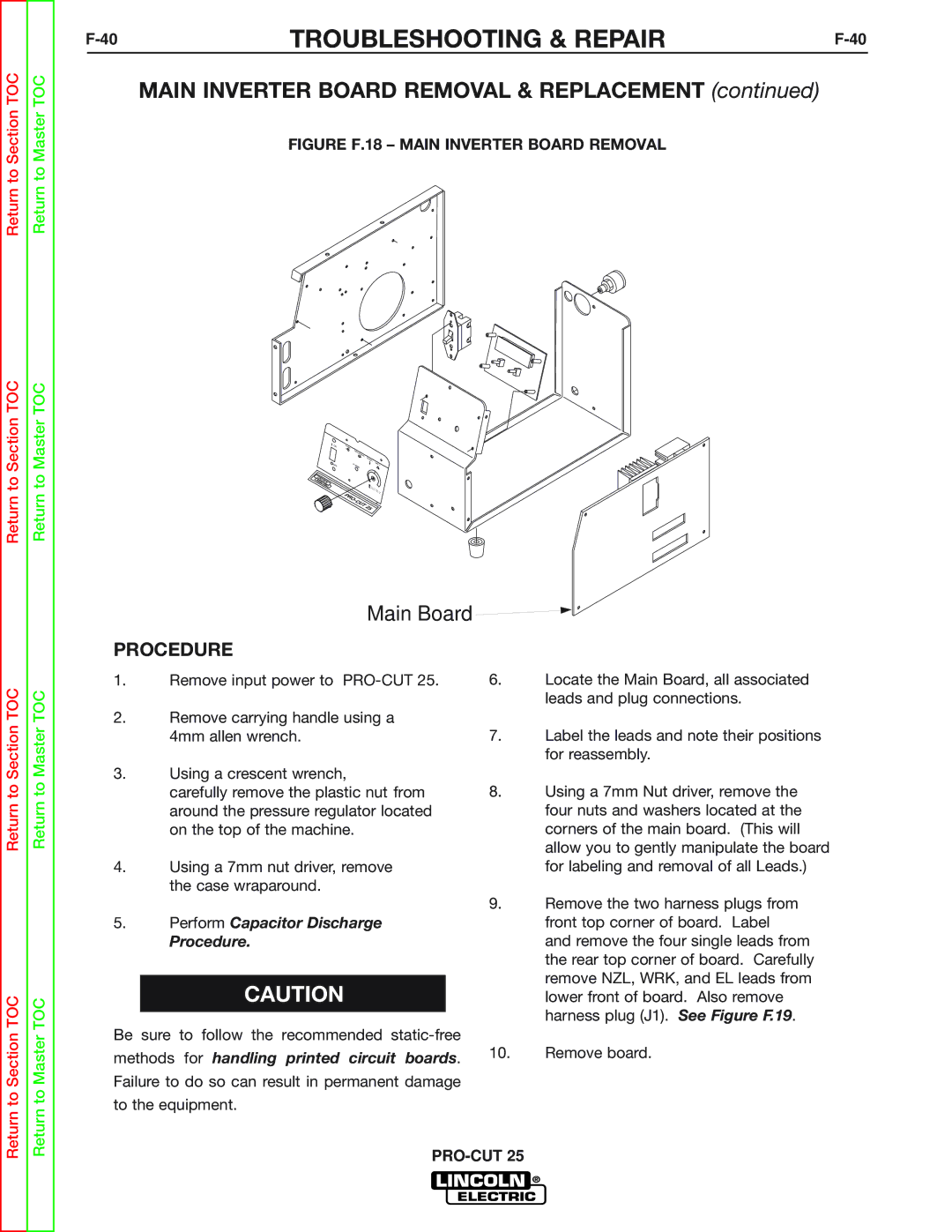

FIGURE F.18 – MAIN INVERTER BOARD REMOVAL

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

ON | POWER |

|

|

| GAS | PRESSURE |

|

|

| THERMAL | |

|

|

| |

OFF | PURGE | SAFETY | |

! | |||

LINCOLN |

|

|

|

ELECTRIC |

|

|

|

| PRO- |

|

|

| CUT | 25 | |

|

|

| |

Main Board

PROCEDURE

1.Remove input power to

2.Remove carrying handle using a 4mm allen wrench.

3.Using a crescent wrench,

carefully remove the plastic nut from around the pressure regulator located on the top of the machine.

4.Using a 7mm nut driver, remove the case wraparound.

5.Perform Capacitor Discharge

Procedure.

![]() CAUTION

CAUTION

Be sure to follow the recommended

6.Locate the Main Board, all associated leads and plug connections.

7.Label the leads and note their positions for reassembly.

8.Using a 7mm Nut driver, remove the four nuts and washers located at the corners of the main board. (This will allow you to gently manipulate the board for labeling and removal of all Leads.)

9.Remove the two harness plugs from front top corner of board. Label and remove the four single leads from the rear top corner of board. Carefully remove NZL, WRK, and EL leads from lower front of board. Also remove harness plug (J1). See Figure F.19.

10.Remove board.