Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR | |||

|

|

| |

TORCH CONTINUITY AND SOLENOID TEST (continued)

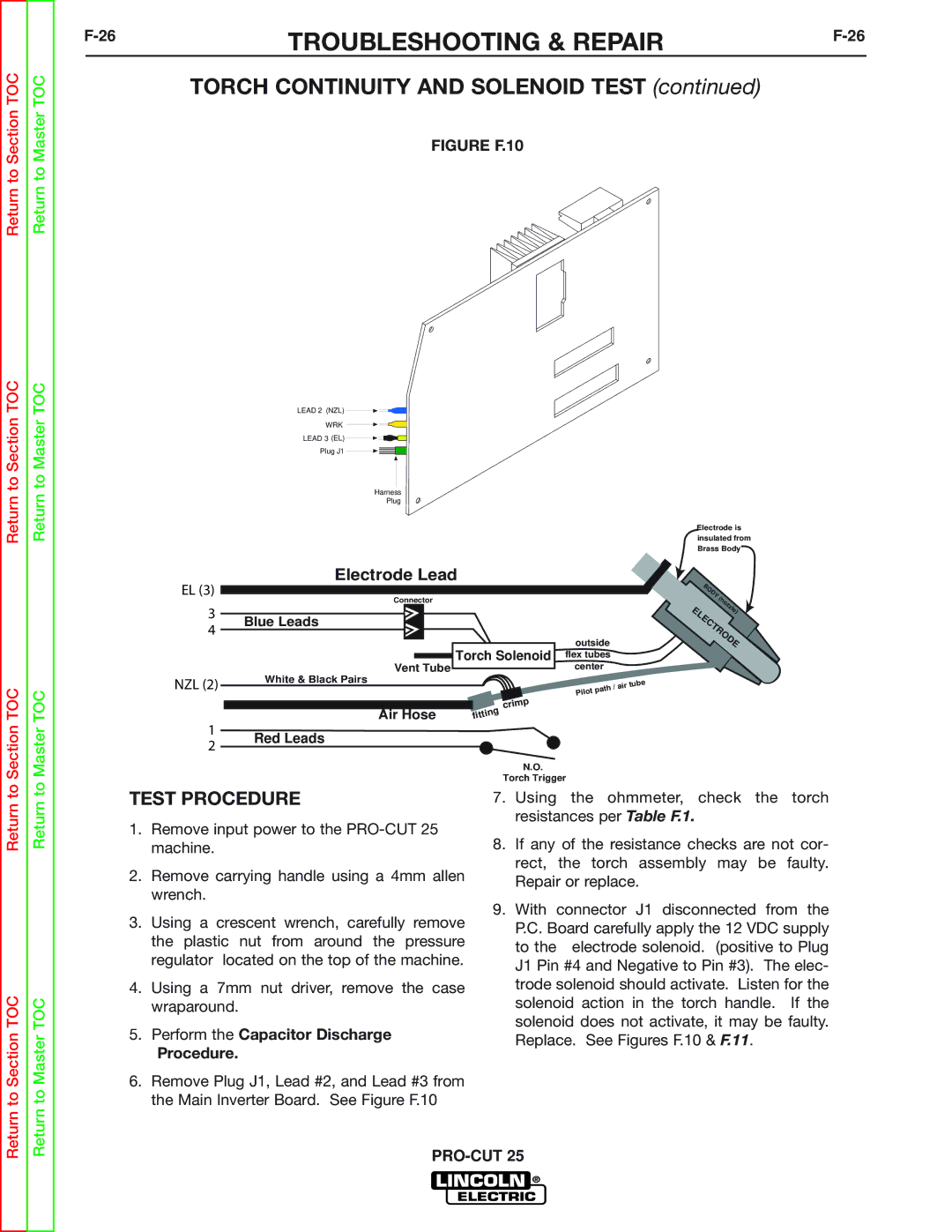

FIGURE F.10

LEAD 2 (NZL)

WRK

LEAD 3 (EL)

Plug J1

Harness

Plug

Electrode is

insulated from Brass Body

Section TOC

Master TOC

Electrode Lead

EL (3)

Connector

3 | Blue Leads | |

4 | ||

outside | ||

| ||

| Torch Solenoid flex tubes |

| Vent Tube | center |

| |

NZL (2) | White & Black Pairs |

| path / air | tube |

|

| |||

| Pilot |

| ||

|

|

|

| |

| Air Hose | crimp |

|

|

| fitting |

|

| |

1 |

|

|

|

|

2 | Red Leads |

|

BODY | (nozzle) |

| |

ELECTRODE | |

Return to

Return to Section TOC

Return to

Return to Master TOC

TEST PROCEDURE

1.Remove input power to the

2.Remove carrying handle using a 4mm allen wrench.

3.Using a crescent wrench, carefully remove the plastic nut from around the pressure regulator located on the top of the machine.

4.Using a 7mm nut driver, remove the case wraparound.

5.Perform the Capacitor Discharge

Procedure.

6.Remove Plug J1, Lead #2, and Lead #3 from the Main Inverter Board. See Figure F.10

N.O.

Torch Trigger

7.Using the ohmmeter, check the torch resistances per Table F.1.

8.If any of the resistance checks are not cor- rect, the torch assembly may be faulty. Repair or replace.

9.With connector J1 disconnected from the P.C. Board carefully apply the 12 VDC supply

to the electrode solenoid. (positive to Plug J1 Pin #4 and Negative to Pin #3). The elec- trode solenoid should activate. Listen for the solenoid action in the torch handle. If the solenoid does not activate, it may be faulty. Replace. See Figures F.10 & F.11.