Section TOC

Master TOC

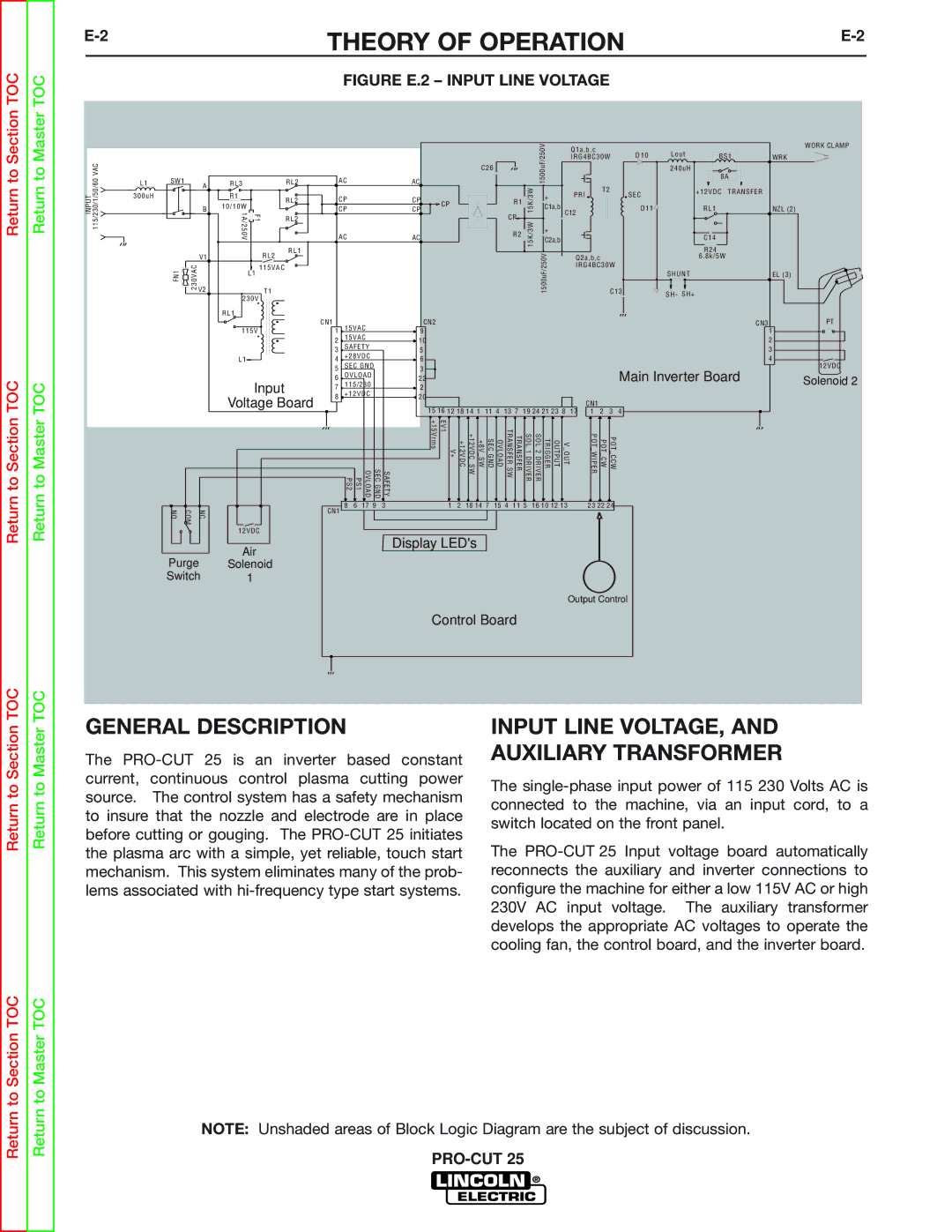

THEORY OF OPERATION

FIGURE E.2 – INPUT LINE VOLTAGE

VAC |

|

| |

INPUT 115/230/1/50/60 | L1 | SW1 | |

A | |||

| |||

300uH |

| ||

| B | ||

|

|

RL3 |

| RL2 |

R1 |

| RL2 |

10/10W |

| |

F1 |

| |

1A/250V | RL2 |

C26

AC | AC |

| |

CP | CP | CP | |

CP | CP | ||

| |||

AC | AC |

|

R1 ![]()

![]()

CP

R2 ![]()

![]()

15K/3W 15K/3W

1500uF/250V

+

C1a,b

+

C2a,b

Q1a,b,c | D10 | Lout | BS1 |

|

IRG4BC30W | WRK | |||

|

| 240uH | 8A |

|

|

|

|

| |

T2 | SEC |

| +12VDC TRANSFER |

|

PRI |

|

|

| |

C12 | D11 |

| RL1 | NZL (2) |

|

|

|

| |

|

|

| C14 |

|

WORK CLAMP

V1 |

RL2

RL1

| R24 |

Q2a,b,c | 6.8k/5W |

IRG4BC30W |

|

FN1 | 230VAC | V2 |

|

|

115VAC

L1

T1

230V

RL1

1500uF/250V

| SHUNT | EL (3) | |

C13 | SH- | SH+ |

|

|

| ||

Return to Section TOC

Return to Master TOC

NO | COM | NC |

Purge Switch

115V

L1

Input

Voltage Board

12VDC

Air

Solenoid

1

CN1 | 15VAC |

| CN2 |

|

|

|

|

|

|

|

|

|

|

|

| CN3 | ||

1 |

| 9 |

|

|

|

|

|

|

|

|

|

|

|

| 1 | |||

2 | 15VAC |

| 10 |

|

|

|

|

|

|

|

|

|

|

|

| 2 | ||

3 | SAFETY |

| 5 |

|

|

|

|

|

|

|

|

|

|

|

| 3 | ||

4 | +28VDC |

| 6 |

|

|

|

|

|

|

|

|

|

|

|

| 4 | ||

5 | SEC GND |

| 3 |

|

|

|

|

|

|

|

|

|

|

|

| Main Inverter Board | ||

6 | OVLOAD |

| 22 |

|

|

|

|

|

|

|

|

|

|

|

| |||

7 | 115/230 |

| 2 |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

8 | +12VDC |

| 20 |

|

|

|

|

|

|

|

|

| CN1 |

|

|

| ||

|

|

|

|

| 15 16 12 18 14 1 |

|

|

|

|

|

|

|

|

| 4 | |||

|

|

|

|

| 11 4 | 13 7 | 19 24 21 23 8 | 17 | 1 | 2 | 3 | |||||||

| PS2 | PS1 | SEC GND OVLOAD | SAFETY | V+ EV1 +15Vrms | +12VDC | +8V SW +12VDC SW | SEC GND | OVLOAD | TRANSFER SW | TRANSFER | SOL 1 DRIVER | V OUT OUTPUT TRIGGER SOL 2 DRIVER |

| POT WIPER | POT CW | POT CCW |

|

CN1 | 8 | 6 | 17 9 | 3 | 1 | 2 | 18 14 7 | 15 4 | 11 5 | 16 10 12 13 |

| 23 22 24 |

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Display LED's

Output Control

Control Board

PT

12VDC Solenoid 2

Return to Section TOC

Return to Master TOC

GENERAL DESCRIPTION

The

INPUT LINE VOLTAGE, AND AUXILIARY TRANSFORMER

The

The

Return to Section TOC

Return to Master TOC

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.