TOC

TOC

TROUBLESHOOTING & REPAIR | |||

|

|

| |

INPUT BOARD VOLTAGE TEST (CONTINUED)

Return to Section

Return to Section TOC

Return to Master

Return to Master TOC

TEST PROCEDURE

1.Remove input power to the

2.Remove carrying handle using a 4mm allen wrench.

3.Using a crescent wrench, carefully remove the plastic nut from around the

pressure regulator located on the top of the machine.

4.Using a 7mm nut driver, remove the case wraparound.

5.Perform the Capacitor Discharge Procedure detailed earlier in this section.

6.Visually check for burned or damaged components on the input board. If any components are physically damaged or determined to be faulty (except the fuse) the input board should be replaced.

7.Check fuse F1 (1 amp). Replace if defective.

8.Apply 115VAC input to the

Note: If the peak input voltage is above 400VAC the thermal light may activate. Reduce the input voltage.

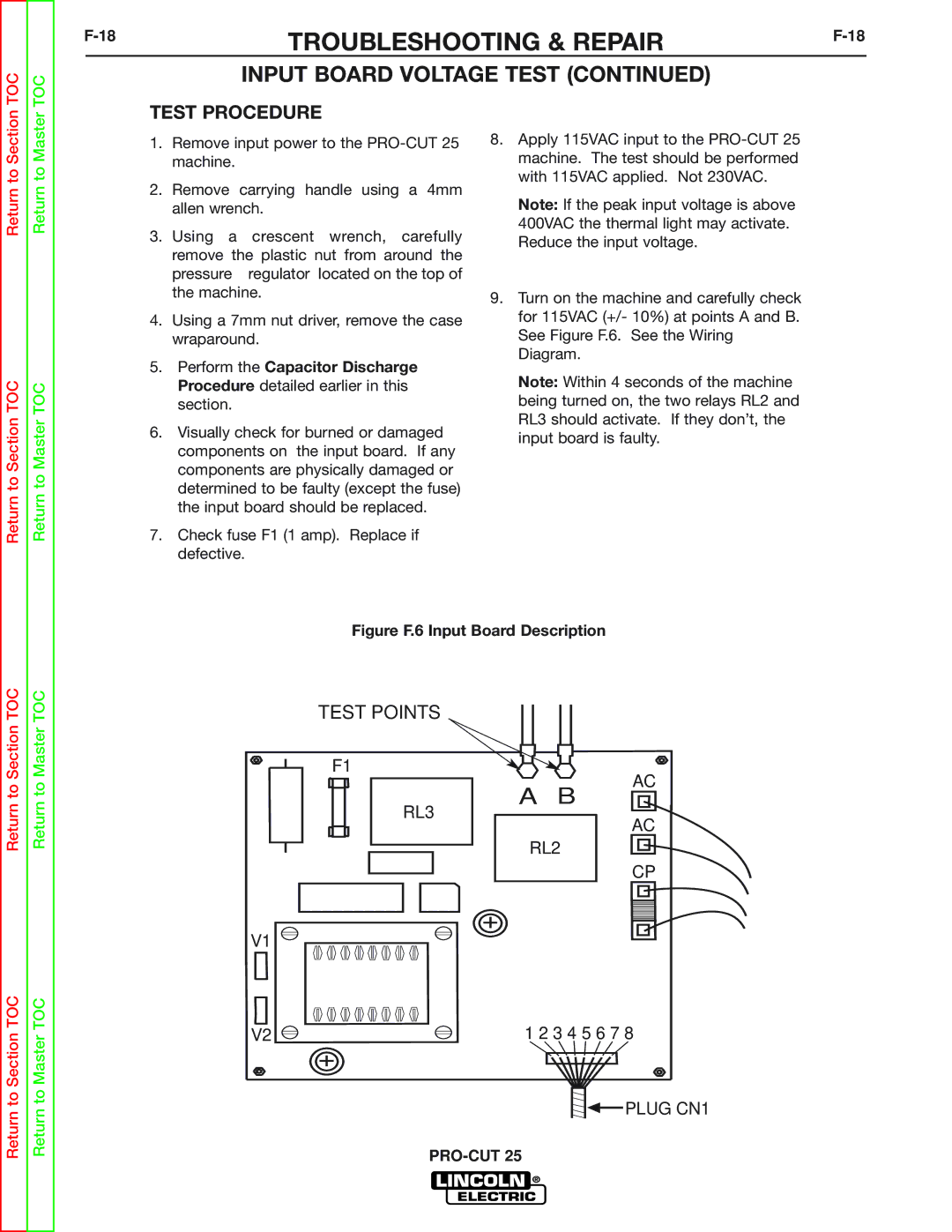

9.Turn on the machine and carefully check for 115VAC (+/- 10%) at points A and B. See Figure F.6. See the Wiring Diagram.

Note: Within 4 seconds of the machine being turned on, the two relays RL2 and RL3 should activate. If they don’t, the input board is faulty.

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Figure F.6 Input Board Description

TEST POINTS

F1

AC

A B

RL3

AC

RL2

CP

V1

V2 | 1 2 3 4 5 6 7 8 |

![]()

![]()

![]() PLUG CN1

PLUG CN1