DM800i Series

DM800i Series Mailing System

Page

SV61162 Rev. D

Alerting Messages

FCC Compliance

FCC Compliance of Modem

Page

Table of Contents

Page

Pitney Bowes Contact Information List

PB Web Sites

Our Help Desk

Postage By Phone System Pitney Bowes Supplies

Page

Read This First

What’s in this Guide Other Information

Read This First

Safety Requirements

What You Need to Know

Requirements

Read This First

Power Stacker

DJPS/DMPS

If your stacker has an AC adapter to power the stacker

Contents Introducing the DM Series Mailing System

Meet the DM800i Series Digitial Mailing System

Meet the DM800i Series Digital Series Mailing System

Energy Star Rating Postage Meter

Easy-to-Use IntelliLink Control Center

DJPS/DMPS Power Stacker

Variety of Communications Options

Ability to Use Other Pitney Bowes Equip- ment

Mail Machine Interface

Inview Accounting

Budget Manager

Business Manager

Advertisements and Inscriptions

Shape Based Rating

Parts of the Mailing System

Mailing System Exterior

Quick Reference Card Set These

Left Side View of the DM800i Series System

DM800i Series System with Optional WOW Module

Connectors on the Back of the Mailing System Base

Top release jam lever Seal bottle

Under the DM800i Series Print Cover

Function Keys

DM800i Series Digital Mailing System Operating Guide

Main Screen

Connectors on the Back of the IntelliLink Control Center

Analog Phone Line Connector

Meet the DM800i Series Digital Series Mailing System

Mail in a Minute

Mail in a Minute Preparing Your Mail

Running the Mail

Select Key In Postage

Printing Postage Tapes

Running Mail

Select Mode

Navigating Hints

Applying Postage Running Mail

Determining the Correct Postage Mode

Chart a Printing on Mail

Feeding Mail or Printing Tape?

Chart B Postage Tape Mode

Chart C Mail Modes with no Postage

Preparing Your Mail

About Running Mail

Adding Postage in this guide

Tips on Feeding

Mail

About Printing Postage Tapes

Selecting the Postage Mode and Running the Mail

Mode Selection Reduced Speed

While your mailing system processes the mail, the screen

Mode Selection Key in Postage WOW Weigh On-The-Way

Select WOW Weigh on the Way

Mode Selection Weigh First Piece Differential Weighing

Select Weigh First Piece

To use differential weighing

Select Differential Weighing

Mode Selection Manual Weight Entry

Select Manual Weight Entry

Mode Selection Attached Scale AutoTape

Before using this weighing option

Select Attached Scale AutoTape

Mode Selection Print Permit Mode Selection Seal Only

To select a Print Permit

Mode Selection Time and Date Stamping

Selecting or Deselecting an Account

Selecting an Account

Selecting an Account Manually

Deselecting an Account

Selecting an Account by Name

Selecting an Account by Speed Code

Selecting the Class, Carrier, Special Services or Options

Selecting ZIP Codes and Zones

Selecting a Country Selecting a Smart Class

Selecting the Meter Stamp Options

Meter Stamp Options Date

Meter Stamp Options Advertisement

Meter Stamp Options

Select Meter Stamp Options, then select Text Entries

Postage Calculation for Confirmation Services

Discounts for Confirmation Services

Overview

Sending Your Records to Pitney Bowes

Using Confirmation Services Before Printing Postage

Adding Services or Making Changes

Adding Confirmation Services After Printing Postage

Running Mail

Installation/Setup

Press Existing Features Press Confirmation Services

Confirmation Services

Setup Options

Select Confirmation Services

Processing Electronic Return Receipt

Select E-Ret Receipt

Enter the Usps tracking barcode number

Using ERR with a Customer Reference Number

Processing ERR with a Customer Reference Number

Off-Line Electronic Return Receipt ERR

Select 1stCl Letter

Select Certified Select Offline eRR

To add more postage

ClearingBatch the Count

To change the date

Running Mail

Mailing System Setup

Contents

Mailing System Setup

Overview Mailing System Set Up

Setting the Display Language Adjusting Display Contrast

Setting the Date and Time of Day

Setting Up a Supervisor Password

Setting Up a Lock Code

Creating a Supervisor Password

Password Protecting an Operation

Setting Up the Scale and Selecting Rates

Scale/Rates Set Up

Scale/Rates

Scale/Rates WOW Weight Limit WOW Start Key Autoscale

Select WOW Weight Limit

Select WOW Start Key

Select Carrier/Class Disp

Select Class if new Piece

Scale/Rates Destination if New Piece

Scale/Rates Autoclear Destination Value

Scale/Rates ZIP/Zone Prompt

Scale/Rates Add ZIPs to Zone

Select BMC Intra ZIP

Select Add ZIPs to Zone

Select Discount Code

Scale/Rates Smart Classes

Creating a Smart Class with an Auto Inscription

To set the next weight break point, select Add Another Class

Setting Up a Smart Class with an Auto Inscription

Scale/Rates Auto Rate Large Envelope

Modifying a Smart Class with an Auto Inscription

Select View Detail Select Modify Auto Ad/Inscription

Yes, Post as Flat

Setting Up Postage By Phone Meter Payment System

Phone/Network Set Up

Select Dialing Prefix

Select My Phone #

Select Dialing Type

Phone/Network Set Up Use LAN Firewall Settings

Phone/Network Set Up Network Settings

Configuring High/Low Funds Warning

Configuring Low Ink Warning

Phone/Network Set Up Remote PC Refill

Setting the Low Funds Warning Value

Timeouts Display Sleep Energy Star

Timeouts

Standby Mode Least Power Usage

Select Basic Settings and then Timeouts Select System Sleep

DM800iSeries Digital Mailing System Operating Guide

Defining Presets

Timeouts Transaction

Defining Normal Preset Values

Press the Custom Presets key

Press the screen key for Store Current Setting to Preset

Defining Custom Preset Values

Select Store Current Setting to Preset

Store Advance Date in a Custom Preset

Editing Custom Preset Values

Viewing, Renaming, or Deleting Presets

Specifications

Sample

Select Set Up, then select Text Entry Set Up

Postal Rules and Guidance

Creating a Custom Message for the First Time

Adding Additional Custom Messages

Editing a Custom Message

Deleting a Custom Message

Select Meter Stamp Option, then select Text Entries

Envelope Guidance Drop Shipment Endorsement

Taking the Meter Out of Service

Adding an Optional Printer

Configuring the Optional Barcode Scanner

Setting Default Scan Type

Adding Barcode Prefixes

Combining Barcodes Setting Auto-Enter

Adding Postage

Postage By Phone Meter Payment System

Your Postage Meter

Usps Rekey Requirements

Connection Alternatives Review

LAN

Managing Your Postage Funds

Connecting Your Control Center to a Remote Analog Line

CheckingAvailable Funds in Your Postage Meter

Adding

Postage Pass Automated Postage Refill

Postage meter, follow these steps

Select Quick Refill, or Other Refill Amount

Recommended Minimum Default $2000 $8000 $1000 $5000

Setting an Account Period

Standard Accounting

Set Up Account

Select Account

Using Account Setup Procedures

Overview of Accounting

Before Using Setup Procedures

CreatingAccounts

Select View Accounts

Select Create Account/Sub

DM800i Series Digital Mailing System Operating Guide

Setting an Account Period

Editing

Accounts

Select Edit Account

DeletingAccounts

Delete

TurningReset Individual Accounts On or Off

Transferring

Funds

Select Transfer Entire Amount, or

Selecting an Accounting Type

Standard

AccuTrac

Your Accounting System Features

Account Structure Hierarchy

Examples

Engineering

Standard Accounting

Reports

Introduction Viewing a Report Printing a Report

Introduction Viewing a Report Printing a Report

Single Account Report

Report Print Queue

Screen Display

Printed Report

Multi-Account Summary Report

Internal Printer Version

External Printer Version

Last Five Refills Report

Confirmation Services Report System Printer Required

Printed Report System Printer

Printed Report Attached Printer

Account List Report External Printer Required Funds Report

System Set Up Report

Error Report

Job Report

DDDDDGGGGG1245

Installed Pending Rates Report

Last Rates Downloaded Report

View Download Log Report

Reports

Contents Items to Keep On Hand

Maintaining and Updating

Maintaining and Updating

Tape is still on roll in this section

Select Maintenance Select Load Tape Select Unload Tape

Tape is still on roll

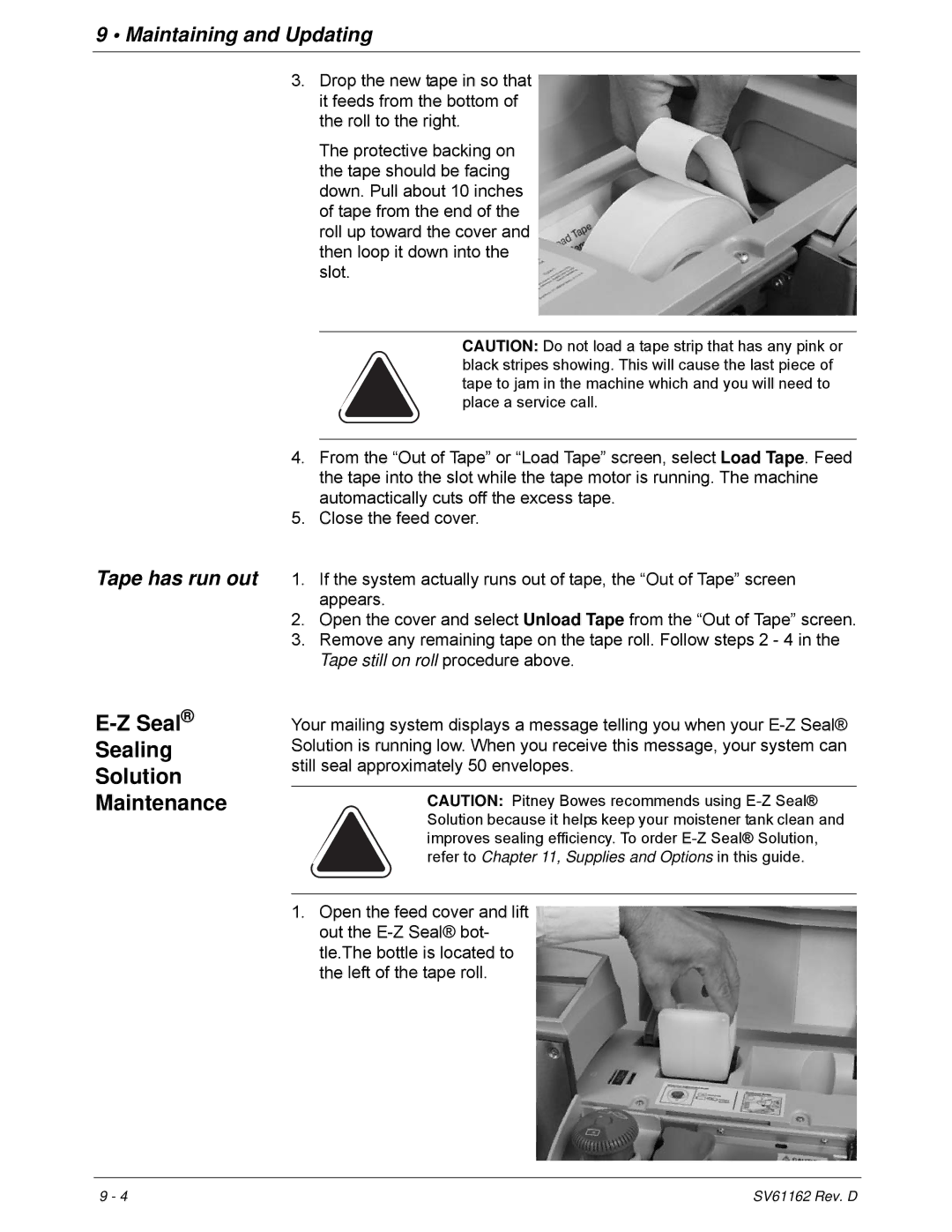

Seal Sealing Solution Maintenance

Moistener Maintenance

Priming the Moistener

Moistener brush button Moistener brush assembly

Printer Maintenance

Cleaning or Replacing the Wick

Adjusting Wetness

Select Maintenance Select Print Test Pattern

No, clean the print nozzle screen key. Go to step

Select Maintenance

Replacing the Ink Cartridge

Maintaining and Updating

Changing the Printhead

Printhead cover

Proceed to Changing the Wiper Blade Assembly section

Changing Wiper Blade Assembly

Select Maintenance Select Replace Wiper Blade Assembly

Performing Updates or Adding Features

Maintaining and Updating

Troubleshooting

How to Troubleshoot your Mailing System

Ink Waste Full Tray Warning

Envelope Sealing Problems

Description Possible Causes Solution

Envelope Feeding Problems

Select Sealer off

To clear a jam in the WOW deck

To clear a jam from the transport deck

Tape Feeding Problems

Printing Problems

Refer to the Changing the Printhead

Postage Refill Problems

Display Problems

Weighing Problems

Scale

To test the scale

Supplies and Options

Confirmation Services Labels

Supplies and Options

Comsumables You Can Order

Self-Adhesive Tape

Specifications

Specifications

Specifications

Dimensions and Weight

Electrical and Operating Conditions

Capacities and Features

Tisements see , Meter Stamp Options section

Specifications Accounting Features

Mailing Materials

Maximum

Minimum

This page intentionally left blank

Glossary

Glossary

PSD

Device PSD

Usps

Glossary

Catalog

Date

Features

Help

10-5,10-6,10-7

Password

Rates

Updates

Using 4-11,4-12WEIGH-ON-THE-WAY Module 2-5Weight

Add 7-4,7-5Subsubaccount

Tape

Page

SV61162revd