8 Service, maintenance and disposal | PAS4•S |

|

|

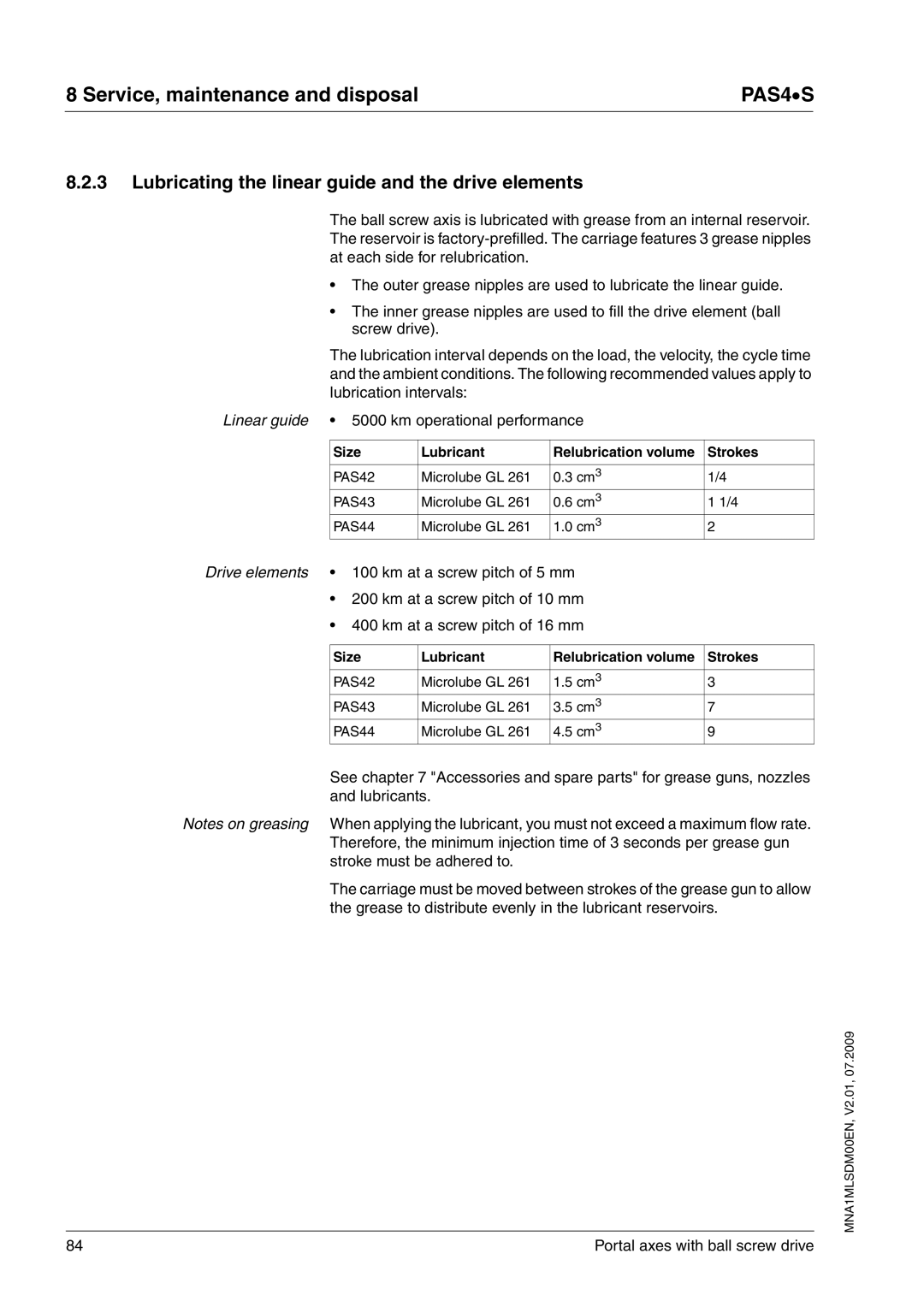

8.2.3Lubricating the linear guide and the drive elements

The ball screw axis is lubricated with grease from an internal reservoir. The reservoir is

•The outer grease nipples are used to lubricate the linear guide.

•The inner grease nipples are used to fill the drive element (ball screw drive).

The lubrication interval depends on the load, the velocity, the cycle time and the ambient conditions. The following recommended values apply to lubrication intervals:

Linear guide • 5000 km operational performance |

| |||

|

|

|

|

|

| Size | Lubricant | Relubrication volume | Strokes |

|

|

|

|

|

| PAS42 | Microlube GL 261 | 0.3 cm3 | 1/4 |

| PAS43 | Microlube GL 261 | 0.6 cm3 | 1 1/4 |

| PAS44 | Microlube GL 261 | 1.0 cm3 | 2 |

Drive elements • 100 km at a screw pitch of 5 mm

• 200 km at a screw pitch of 10 mm

• 400 km at a screw pitch of 16 mm

Size | Lubricant | Relubrication volume | Strokes |

|

|

|

|

PAS42 | Microlube GL 261 | 1.5 cm3 | 3 |

PAS43 | Microlube GL 261 | 3.5 cm3 | 7 |

PAS44 | Microlube GL 261 | 4.5 cm3 | 9 |

See chapter 7 "Accessories and spare parts" for grease guns, nozzles and lubricants.

Notes on greasing When applying the lubricant, you must not exceed a maximum flow rate. Therefore, the minimum injection time of 3 seconds per grease gun stroke must be adhered to.

The carriage must be moved between strokes of the grease gun to allow the grease to distribute evenly in the lubricant reservoirs.

MNA1MLSDM00EN, V2.01, 07.2009

84 | Portal axes with ball screw drive |