Documentation

Communication for the open minded

Contents

Contents

Contents

Contents

Contents

Contents

Contents

Contents

Images

Images

Images

Tables

Tables

Tables

Tables

Tables

Tables

Tables

Target audience and qualifications

Conventions and Operating Instructions

Reference manuals

Lar importance or that must be heeded appear in bold print

Notations and symbols

Symbols

Conventions

Privacy and data security

Overview

Overview

Example application

Description of functions

Example application

Interactions of the DCO components

Tasks of the DCO-Script

Tasks of the OScAR-Pro Customized Operator

Tasks of the OScAR-Pro-TT Operator-Tool

Installation

Task Window

How to install the OpenScape Alarm Response Professional

No. Task Window

How to install OScAR-Pro Customized Operator 07/2010

Task Window

Uninstall the OpenScape Alarm Response Professional

No. Task

Uninstall the OpenScape Alarm Response Professional

Operating Instructions for the OScAR-Pro Customized Operator

Task

Start the OScAR-Pro Customized Operator

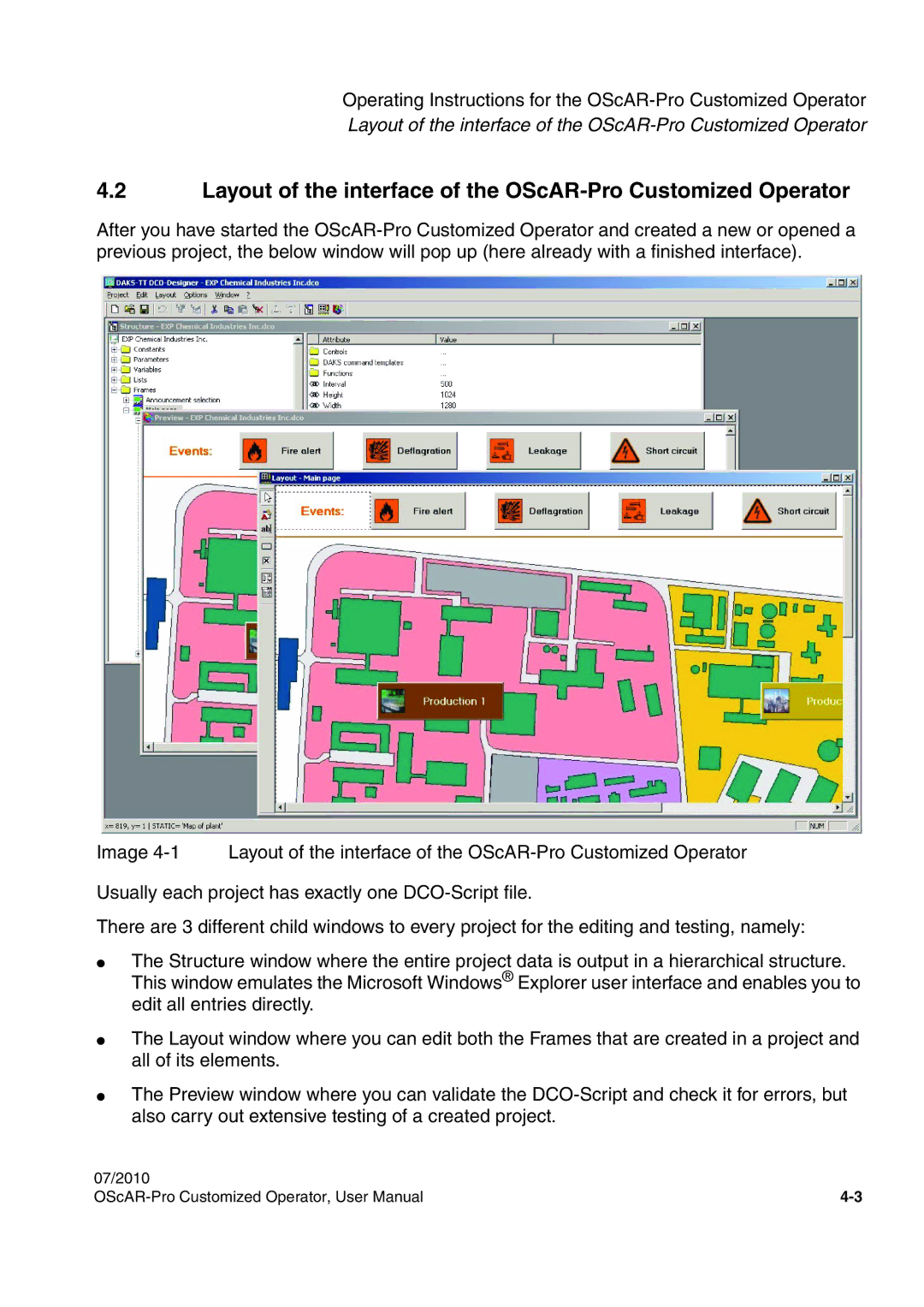

Layout of the interface of the OScAR-Pro Customized Operator

Toolbar

Menu bar

New

Menu item Description Generic entries

Menu item Description

Default colors

Edit

Moves an entry up in the order of the list view

Move up

Pointer

Menu item Description Special entries in the Layout window

Menu item Description

Functions of the mouse

Special entries of the Preview window

Left mouse key Drag & Drop with the left mouse key

Right mouse key Context menu

Status bar

Setup and application of the Structure window

Tree structure of the Structure window

Edit entries

List view of the Structure window

Change the sequence of the columns

Sort the list

Setup and application of the Layout window

Control Description

Toolbar and Controls

Button Description

Mark a Frame area or a Control

Move Controls

Position of the black square Cur Sor

Change the size of Frames and Controls

Align and space elements automatically

Setup and application of the Preview window

Edit project properties

General user dialog windows

Administration of the Image lists

General user dialog windows

Process colors and Standard colors for process lists

General user dialog windows

Input field Description

Edit fonts

General user dialog windows

Edit colors

Input field Description

Elements of a DCO-Script

07/2010

07/2010

07/2010

General structure

Node Description

Data type Value range Description

DCO data types and their value ranges

Examples

MUL

Formulas

DIV

Effect on Tion Numeric elements Text elements

Attribute

Constants

Attributes of Constants

Example

Edit the attributes of a Constant

Add a new Constant

Parameters

Add a new Parameter group

Attribute Description

Attributes of Parameters

Edit the attributes of a Parameter

Add a new Parameter

Attributes of Variables

Variables

Edit the attributes of a Variable

Add a new Variable

Lists

Short summary of the Data lists

Short summary of Filters

Attributes and child nodes of the node Data lists

Attributes of Data lists

Child nodes of the node Data lists Description

Color

Attributes of data elements

Edit the attributes of a Data list

Add a new Data list

Edit the attributes of a data element

Add a new data element

Attributes of Filters

Attributes and child nodes of the node Filters

Child nodes of the node Filters

Child node Description

Attributes of ID ranges

Attributes of excluded IDs

Attributes of Included IDs

Example

Edit the attributes of a Filter

Add a new Filter

Edit the attributes of an ID range

Add an ID range

Edit the attributes of an Included ID

Add an Included ID

Edit the attributes of an Excluded ID

Add an Excluded ID

Frames

Attributes and child nodes of the node Frames

Attributes of Frames

Int

Bool

Bool or

„OnMessage

„OnTimer

Child nodes of the node Frames

OnLoad

Edit the attributes of a Frame

Add a new Frame

Add a new Control through the Structure window

Add a new Control through the Layout window

Edit the attributes of a Control

Attribute Description Global attributes

OScAR-Pro command templates

Attribute Description

Byte

Attribute Description Additional attributes of the type BDC

String

Byte, or

Bool , or

Attribute Description

Attribute Description Child nodes of the node BDC

Bdcid

Msgid

Itlid

Additional attributes of the OScAR-Pro command ITL

Attribute Description Additional attributes of the type CON

Conid

Phonenumber

Additional attributes of the OScAR-Pro command Callwhi

Bool

TAN

Uint

Bdcid

Conid

Add a new OScAR-Pro command template

Edit the attributes of a OScAR-Pro command template

Add a new Function to a Frame

„OnLoad

„User

Edit the attributes of the Functions of a Frame

Use of Controls

Controls

Attribute Description

References to Controls

Attributes shared by all Controls

Color

Attribute Description

Special attributes of Static elements

Child nodes and special attributes of Static elements

Attributes of the child node Image of a Static element

Child nodes of Static elements

Attribute Description

Attribute Description

Attributes of the child node Caption of a Static element

Position Font Elements of a DCO-Script

Special attributes of Edit fields

Bool

Special attributes of Buttons

Special attributes and child nodes of Buttons

Color of the title of the Button can be changed during

Child nodes of Buttons

Add Functions to a Button

Edit the attributes of the Functions of a Button

Add Static elements to a Button

Edit the attributes of the Static elements of a Button

Special attributes of Checkboxes

Title of a Checkbox can be changed during the execution

Child nodes and special attributes of Listboxes

Special attributes of the type process

Child nodes of Listboxes

Child node Description For the type process

For all other types

Attributes of Process filters Child node Description

For the Rocessbdcmbr

Child node Description For the type Processconmbr

Double-click events of Listboxes

Add new Process filters to Listboxes

Edit the attributes of Process filters

Child nodes of Comboboxes

Child nodes and special attributes of Comboboxes

Selection events of Comboboxes

Functions

Attributes and child nodes of Functions

Attributes of Functions

Child nodes of the node Functions

Operators

Setup and syntax of conditions

General

Syntax

Example of a condition with several elements

Instruction Description Control Instructions

Instructions

Arguments of Instructions

Overview of Instructions

Instructions for Static elements

Instruction Description

Instructions to set Variables

Instructions to change the attributes of Frames

Instructions for Buttons

Instructions for Edit fields

Instructions for Checkboxes

Instructions for Comboboxes

Instructions for Listboxes

Add a new Instruction

Edit Instructions

Open

Change the order in which the Instructions are executed

Arguments Description

Instruction AddListToComboBox

Instruction Call

Instruction BroadcastMessage

Instruction ClearComboBox

Instruction Execute

Instruction GetBroadcasts

Instruction GetConferences

Instruction GetComboBoxSelText

Instruction GetInfotelephones

Instruction GetListBoxSelText

Instruction GetMessages

Instruction GetScenarios

Instruction OffAllListBoxItemBlink

Instruction GotoFrame

Instruction OffEditBackColorBlink

Instruction OffButtonBlink

Instruction OffEditTextColorBlink

Instruction OffListBoxItemBlink

Color, or

Instruction SetButtonBlink

119

Instruction SetButtonColor

String , or

Instruction SetButtonPicture

Float

Instruction SetButtonPictureScal

Instruction SetButtonRect

Instruction SetButtonStaticBackColor

Color , or

Instruction SetButtonStaticBorderColor

Instruction SetButtonStaticPictureName

Bottom , h-center, bottom , and right, bottom to find

Instruction SetButtonStaticPicturePos

Choose from left, top , h-center, top , right, top

Left, center , h-center, v-center , right, center , left

Instruction SetButtonStaticPictureScale

Instruction SetButtonStaticRect

Uint, or

Instruction SetButtonStaticStatus

Instruction SetButtonStaticText

Instruction SetButtonStaticTextColor

Instruction SetButtonStaticTextPosition

Instruction SetButtonStatus

Instruction SetButtonText

Instruction SetButtonTextColor

Instruction SetCheckBoxBackColor

Instruction SetCheckBoxCaption

Instruction SetCheckBoxRect

Bool, or

Instruction SetCheckBoxState

Uint , or

Instruction SetCheckBoxStatus

Instruction SetCheckBoxTextColor

Instruction SetCheckBoxToVariable

Instruction SetComboBoxBackColor

Instruction SetComboBoxList

Instruction SetComboBoxRect

Instruction SetComboBoxStatus

Instruction SetComboBoxTextColor

Instruction SetComboToVariable

Instructions SetEditBackColor

Instruction SetEditBackColorBlink

152

Instruction SetEditRect

Instruction SetEditStatus

Instruction SetEditText

Instruction SetEditTextColor

Instruction SetEditTextColorBlink

158

Instruction SetEditToVariable

Instruction SetFrameColor

Instruction SetListBoxBackColor

Instruction SetListBoxBlinkTime

Instruction SetListBoxItemBlink

Instruction SetListBoxItemColor

Instruction SetListBoxList

Instruction SetListBoxRect

Instruction SetListBoxSelectionToVariable

Instructions SetListBoxStatus

Instruction SetListBoxTextColor

Instruction SetListBoxToVariable

Instruction SetStaticBackColor

Instruction SetStaticBorderColor

Instruction SetStaticPictureName

Bottom, h-center, bottom, and right, bottom to find

Instruction SetStaticPicturePos

Choose from left, top, h-center, top, right, top

Left, center, h-center, v-center, right, center, left

Instruction SetStaticPictureScale

Instruction SetStaticRect

Instruction SetStaticStatus

Instruction SetStaticText

Instruction SetStaticTextColor

Instruction SetStaticTextPosition

Instruction SetVariable

Instruction StartProgram

Planning and implementation of a DCO Project

07/2010

07/2010

Case study requirements

Case study project

Case study plant map

Objects administrated in OScAR-Pro

Name Description Subscribers

Announcements

How to implement the case study

Name Description Broadcasts

Structure of the case study user interface

Functions of the Main

Global objects

Functions of the Frames child node Announcement selection

Task References

Project administration Create the project

Open an existing project

Main

Create Frames and Controls

Create and customize the Frames

Create the Main

Nouncement selection

1024

Add a background image to the Main

Plant map

1280

Add visual separators to the Main

Add Captions to the Main

Italics

Event name

Hints

Left, v-center

Select event\n Select area\n Invoke

820

Add Buttons to the Main

Insert Event Buttons

Fire alert

490

Deflagration

310

Leakage

200

Create Area Buttons

Management

875

630

AdminTechnics

Admin &&Technics

160

Start.GIF

Disabled

Create an Invoke Button

932

Add Controls to the Frame Announcement selection

Cancel

470

Ok.GIF

Screenshot of the Structure window

Screenshot of the final interface

Screenshot of the Main

Screenshot of the page Announcement selection

Name Data type Value Description

Create the global objects Create Constants

Create the Parameters

Create the Variables

Create the Lists

Announcement IDs

Create the OScAR-Pro command template Invoke broadcast

Attributes

Broadcast IDs

Create the Functions of the Main

User Function Fire alert blink on

Instructions

User Function Leakage blink on

User Function Deflagration blink on

User Function More blink on

User Function Short circuit blink on

User Function Management blink on

User Function AdminTechnics blink on

User Function Production 2 blink on

User Function Production 1 blink on

User Function Enable invoke

User Function Disable invoke

User Function Activate invoke

User Function Blink Buttons

Create the Functions of the Main

User Function Reset areas

User Function Reset events

User Function Invoke Management

User Function Invoke AdminTechnics

User Function Invoke Production

OnLoad Function Set Buttons

Functions of the Button Fire alert

Function Delete Description

Function Set Description

Functions of the Button Deflagration

Function Set Description

Functions of the Button Leakage

Name Set Condition $Leakage blinking$ Messagebox

Functions of the Button Short circuit

Name Set Condition $Short circuit blinking$ Messagebox

Functions of the Button More Open announcement selection

Functions of the Button Management

Functions of the Button AdminTechnics

Functions of the Button Production

Name Delete Condition $Production 2 blinking$ Messagebox

Functions of the Button Invoke Invoke broadcast

Create the Functions of the Frame Announcement selection

OnLoad Functions Fill announcement list

Functions of the Button Cancel Cancel dialog

Function With selection Description

Functions of the Button Ok

Function Without selection Description

Test the DCO-Script

DCO in the OScAR-Pro-TT Operator-Tool

Layout in the OScAR-Pro-TT Operator-ToolNote

Publication of the DCO Script

DCO in the child window

DCO in the toolbar

Menu bar and buttons

Operation of the DCO-Window

Operation of the DCO-Window

Keyboard shortcut Ctrl+SHIFT+F4 or click in the toolbar

No. Task

Description of the window DCO parameter editor Edit field

DCO Parameter Editor

Entry Description

Special registry entries for the DCO

Index

Symbole

Index

Index

Index

Killbdc Killcon Killprc

Logical

Index

Showcon

Index

Index