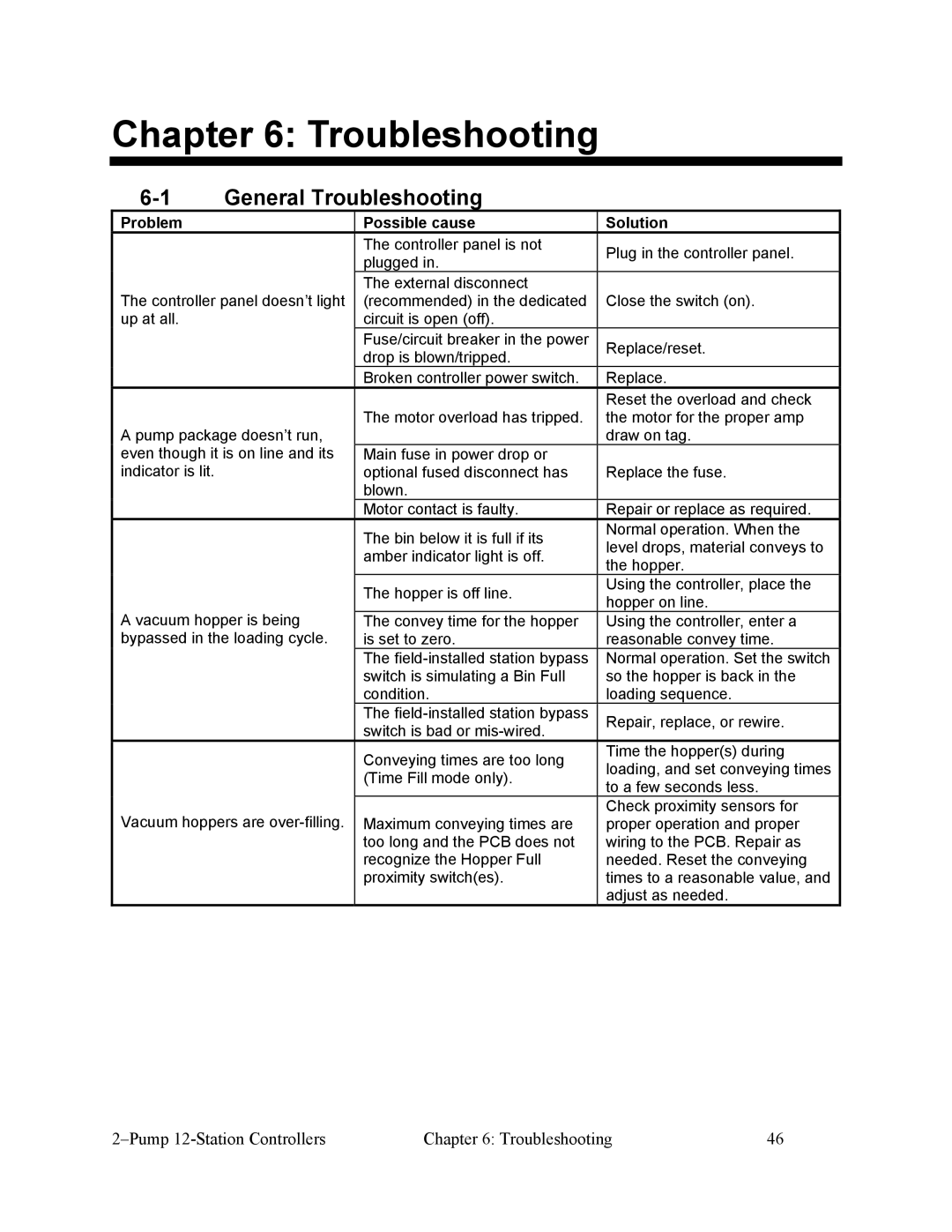

Chapter 6: Troubleshooting

General Troubleshooting |

| ||

Problem |

| Possible cause | Solution |

|

| The controller panel is not | Plug in the controller panel. |

|

| plugged in. | |

|

|

| |

|

| The external disconnect | Close the switch (on). |

The controller panel doesn’t light | (recommended) in the dedicated | ||

up at all. |

| circuit is open (off). |

|

|

| Fuse/circuit breaker in the power | Replace/reset. |

|

| drop is blown/tripped. | |

|

|

| |

|

| Broken controller power switch. | Replace. |

|

|

| Reset the overload and check |

|

| The motor overload has tripped. | the motor for the proper amp |

A pump package doesn’t run, |

| draw on tag. | |

even though it is on line and its | Main fuse in power drop or |

| |

indicator is lit. |

| optional fused disconnect has | Replace the fuse. |

|

| blown. |

|

|

| Motor contact is faulty. | Repair or replace as required. |

|

| The bin below it is full if its | Normal operation. When the |

|

| level drops, material conveys to | |

|

| amber indicator light is off. | |

|

| the hopper. | |

|

|

| |

|

| The hopper is off line. | Using the controller, place the |

|

| hopper on line. | |

A vacuum hopper is being |

| ||

The convey time for the hopper | Using the controller, enter a | ||

bypassed in the loading cycle. | is set to zero. | reasonable convey time. | |

|

| The | Normal operation. Set the switch |

|

| switch is simulating a Bin Full | so the hopper is back in the |

|

| condition. | loading sequence. |

|

| The | Repair, replace, or rewire. |

|

| switch is bad or | |

|

|

| |

|

| Conveying times are too long | Time the hopper(s) during |

|

| loading, and set conveying times | |

|

| (Time Fill mode only). | |

|

| to a few seconds less. | |

|

|

| |

Vacuum hoppers are | Maximum conveying times are | Check proximity sensors for | |

proper operation and proper | |||

|

| too long and the PCB does not | wiring to the PCB. Repair as |

|

| recognize the Hopper Full | needed. Reset the conveying |

|

| proximity switch(es). | times to a reasonable value, and |

|

|

| adjust as needed. |

| Chapter 6: Troubleshooting | 46 |