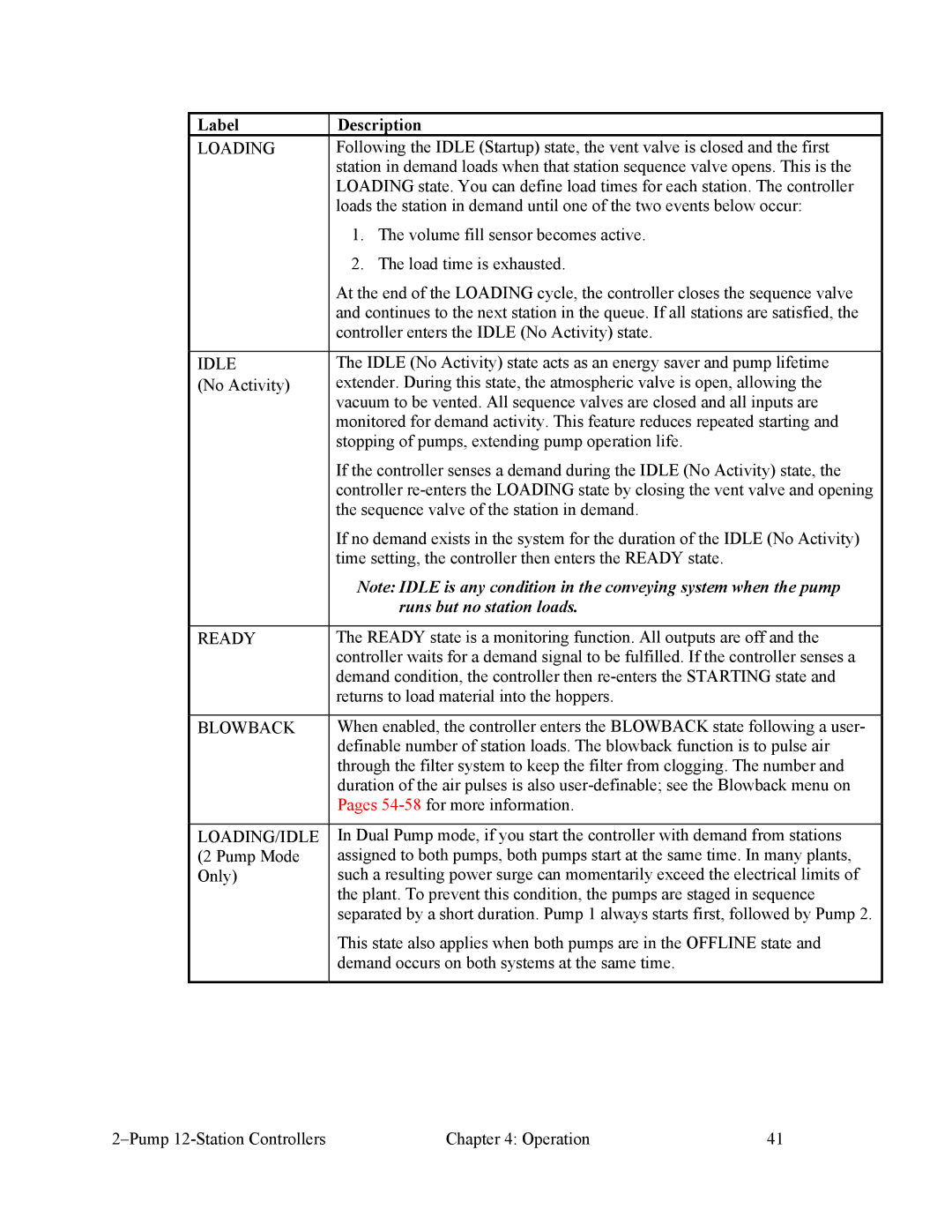

Label | Description |

LOADING | Following the IDLE (Startup) state, the vent valve is closed and the first |

| station in demand loads when that station sequence valve opens. This is the |

| LOADING state. You can define load times for each station. The controller |

| loads the station in demand until one of the two events below occur: |

| 1. The volume fill sensor becomes active. |

| 2. The load time is exhausted. |

| At the end of the LOADING cycle, the controller closes the sequence valve |

| and continues to the next station in the queue. If all stations are satisfied, the |

| controller enters the IDLE (No Activity) state. |

|

|

IDLE | The IDLE (No Activity) state acts as an energy saver and pump lifetime |

(No Activity) | extender. During this state, the atmospheric valve is open, allowing the |

| vacuum to be vented. All sequence valves are closed and all inputs are |

| monitored for demand activity. This feature reduces repeated starting and |

| stopping of pumps, extending pump operation life. |

| If the controller senses a demand during the IDLE (No Activity) state, the |

| controller |

| the sequence valve of the station in demand. |

| If no demand exists in the system for the duration of the IDLE (No Activity) |

| time setting, the controller then enters the READY state. |

| Note: IDLE is any condition in the conveying system when the pump |

| runs but no station loads. |

|

|

READY | The READY state is a monitoring function. All outputs are off and the |

| controller waits for a demand signal to be fulfilled. If the controller senses a |

| demand condition, the controller then |

| returns to load material into the hoppers. |

|

|

BLOWBACK | When enabled, the controller enters the BLOWBACK state following a user- |

| definable number of station loads. The blowback function is to pulse air |

| through the filter system to keep the filter from clogging. The number and |

| duration of the air pulses is also |

| Pages |

|

|

LOADING/IDLE | In Dual Pump mode, if you start the controller with demand from stations |

(2 Pump Mode | assigned to both pumps, both pumps start at the same time. In many plants, |

Only) | such a resulting power surge can momentarily exceed the electrical limits of |

| the plant. To prevent this condition, the pumps are staged in sequence |

| separated by a short duration. Pump 1 always starts first, followed by Pump 2. |

| This state also applies when both pumps are in the OFFLINE state and |

| demand occurs on both systems at the same time. |

|

|

Chapter 4: Operation | 41 |