Split Type

Contents

Original instruction

Work undertaken Protective gear worn

Explanation of indications

Explanation of illustrated marks

Indication Explanation

Confirmation of warning label on the main unit

Description

Precaution for Safety

Proceeding with the repair work

Refrigerant used by this air conditioner is the R410A

Resistance and water drainage

Explanations given to user

Specifications

Model Sound power level dB Weight kg Cooling Heating

Relocation

Copper pipe Piping

Safety Caution Concerned to New Refrigerant

Pipe Materials

Flare nut

R410A Conventional air

Tools

General tools Conventional tools can be used

Used tool Usage

Concealed Duct High static pressure Type

Model Indoor unit

Concealed Duct High static pressure Type Contined

RAV-SM2242DT-TR RAV-SM2802DT-TR

Indoor Unit

SM2242DT-E

Dimension table

Indoor unit

Indoor

Unit

RAV-SM2242 type

100

RAV-SM2802 type

350 300 250 200 150 100 3200 3360

Standard Middle static pressure F2

Wire connection change of fan motor

Low static pressure F1

High static pressure F3

Specifications of Electrical Parts

Parts name Type Specifications

Indoor unit #1 Header

Indoor Controller Block Diagram

Connection of Wired Simple Remote Controller

Outdoor unit

Outside temp Correction value a

Outline of specifications Remarks

Control outline

Setup data

Indoor formation

Ta ˚C Cooling +1.5

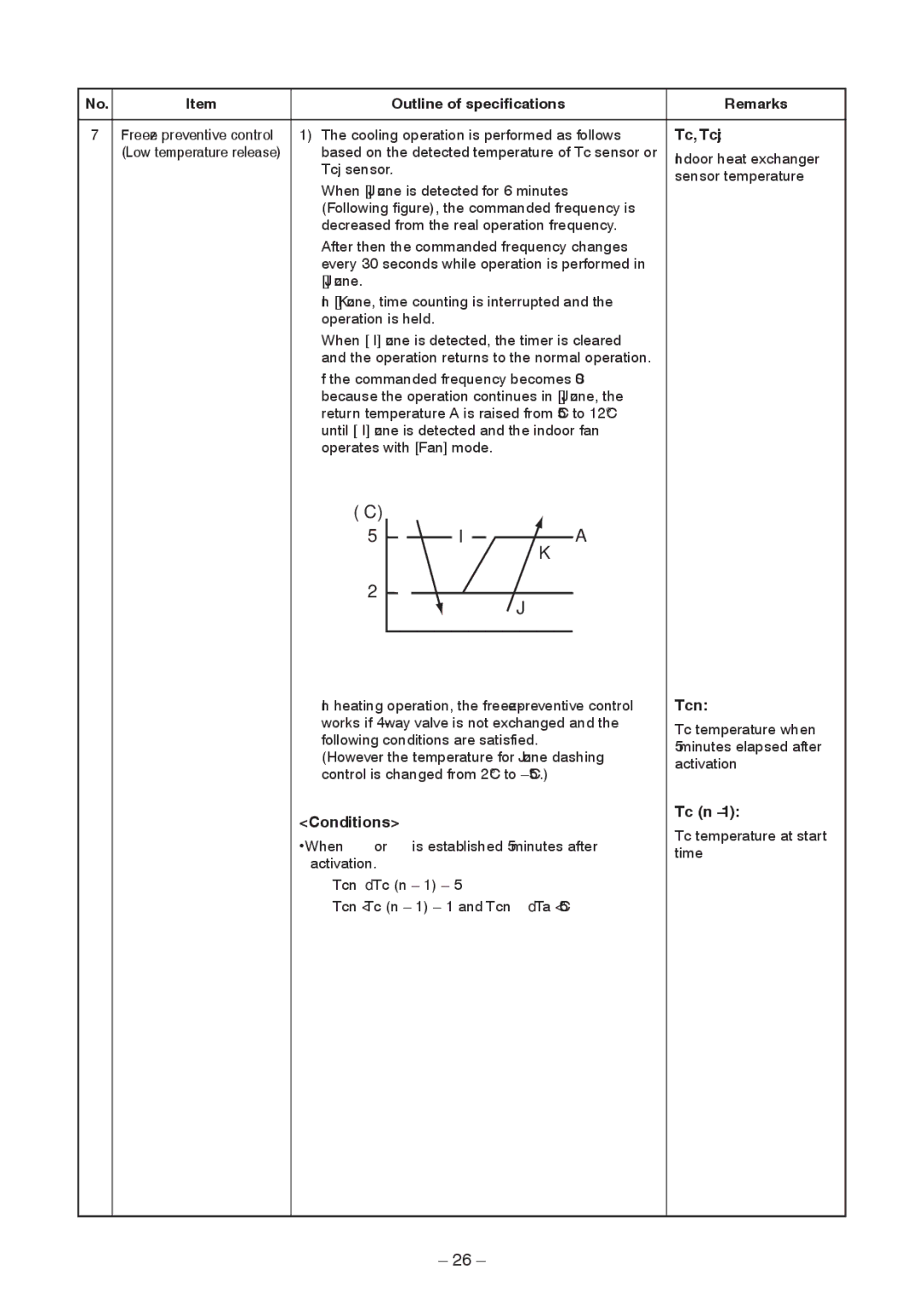

Conditions Tc n

Tc, Tcj

Tcn

Setup at shipment

Control temp. C

Case of wired remote controller

Heat

Usual control

Print Circuit Board

MCC-1403

Optional Connector Specifications of Indoor P.C. Board

Function Connector Pin Specifications Remarks

Wired remote controller type

Before troubleshooting

Troubleshooting procedure

How to read check monitor display

Main remote controller RBC-AMT32E

Confirmation of error log

Procedure

Remote controller switch monitoring function

Central control devices detected

Check Code List Indoor Indoor unit detected

Remote controller detected

Cause of operation Status

Error mode detected by indoor unit

Operation of diagnostic function Judgment and measures

Series

Error mode detected by outdoor unit

After

H03 Current detection circuit error Stop

Power supply error of remote controller, Indoor

E09 error

YES

E04 error

E10 error

L09 error

E18 error

E08, L03, L07, L08 error

P30 error Central controller

L20 error

L30 error

P10 error

P01 error

P19 error

F02 error

F01 error

C06 error 11 model connection interface

P31 error Follower indoor unit

E03 error Master indoor unit

F29 error

TA, TC, TCJ sensors

Temperature Resistance value characteristic table

Temperature sensor TA, TC, TCJ

Representative value

Part name Checking procedure

Resistance value

Replacement of Service P.C. Board

Replacement procedures

Code No. required at least Contents

Setting data read out from Eeprom

C. Board for indoor unit servicing replacement procedures

Operation is available again

Writing the setting data to Eeprom

Step

Type Code No

Indoor unit capacity Code No

Test Run Setup on Remote Controller Wired remote controller

Practical operation

D203 Red

Function Selection Setup

LED Display on Indoor P.C. Board D002 Red

TEMP. buttons, specify the Code No. DN

Contents

Function selection item No. DN list

How to set wired remote controller as sub remote controller

Wired remote controller

Setup method

When connected 2 remote controllers operate an indoor unit

Contents

Pushing Test button returns the display to usual display

Calling of error history

Group control operation

System example

Indoor unit power-ON sequence

Power on

Model Connection Interface Function

Microprocessor block diagram

Model connection interface wiring connection

Model name TCB-PCNT30TLE2

Wiring specifications

C. board switch SW01 setup

Push Test + Vent buttons for 4 seconds or more

External view of P.C. board assembly

Address setup

Push Test button

During unset time, At shipment from factory is displayed

Code No Data at shipment Setup data range

System Configuration

Address Setup & Group Control Terminology

Automatic Address Example from Unset Address No miswiring

Only turning on source power supply Automatic completion

Push SET Button. OK when display goes on Push Test

Using the temperature setup Buttons

Using timer time Buttons, set the line address

Push

To know the position of indoor unit body by address

Procedure

Confirmation of indoor unit No. position

Contents

Precautions for Safety

Concealed Duct High Static Pressure Relocation

Symbol Description

Examples of indication on the carton

Other cautions Description

Display section

Wired Remote Controller

Part Names

Operation section

Start

Correct Usage

Preparation

Stop

Push button during operation

Timer Operation

Power Saving Mode

Set

Energy Saving Recommendations

Advanced Settings

Power saving mode

Maintenance List

Maintenance

Cleaning air filters

Preparing for long Shut Down Period

AIR Conditioner Operations and Performance

Installation

Do not install the air conditioner in the following places

Be careful with noise or vibrations

Troubleshooting

Specifications

Installation Manual

Definition of Protective Gear

Work undertaken Protective gear worn

General

Selection of installation location

Electrical wiring

Refrigerant piping

To Disconnect the Appliance from Main Power Supply

Accessory Parts

New Refrigerant Air Conditioner Installation

Installation space Unit mm

Selection of Installation Place

Installation under high-humidity atmosphere

Filter cleaning sign term setting

Installation of indoor unit

External Dimensions

Installation of hanging bolt

Installation of hanging bolt

Duct design

Diagrams for making connecting flanges

Duct installation example First floor

Air outlet port flange

RAV-SM2802 Type

FAN Characteristics

RAV-SM2242 Type

Low static pressure F1

Wire connection change of fan motor

Drain Piping Work

Standard Middle static pressure F2

Drain up

Connecting drain pipe

Pipe material, size and insulator

Check the draining

Refrigerant Piping

Refrigerant Piping and Evacuating

Heat insulating process

Liquid side refrigerant pipe connection

Gas side refrigerant pipe connection

Evacuation

Power and Wiring Specification

Wire connection

Wiring diagram

Electrical Connection

Wiring diagram

Remote Controller Wiring

Changing of setting applicable control

Applicable Controls

Concealed Duct High Static Pressure Procedure

Remote controller switch monitoring function

Filter sign setting

To secure better effect of heating

Installation Manual Procedure

Procedure example

Manual address setup procedure

Group control

Procedure

8C Operation

Before test run

Daily maintenance

Test RUN

Execute a test run

Confirmation and check

Confirmation of error log

Concealed Duct High Static PressureInstallation Manual

Error codes and parts to be checked

Status

Fan assembly

How to replace the parts Fan assembly and replacement

Part name Work procedure Remarks

Pull out the fan assembly a fan toward you

Fan/Fan case

104

Fan motor

Location Description

2242DT-E

215, 216 219 218 214218 213

108

Check of Concentration Limit

Toshiba Carrier Corporation