R5 | 9100 Top Bracket | |

| ||

|

| |

|

| |

Tools Needed: | If installing an idrive® opener on an installed | |

Power Drill | 9100 door, the top bracket and roller | |

location will have to be adjusted for the | ||

7/16" Socket | ||

opener to work properly. | ||

Driver | Loosen the (2) | |

Step Ladder | ||

bracket slide. | ||

| Remove the (4) | |

| screws from the top bracket. | |

| Raise the top bracket to align the bottom | |

| slots with the second set of holes in the | |

| end cap. | |

|

| |

| the (4) | |

| ||

| by moving the top bracket slide out to force | |

| the door section against the weather seal. | |

| Tighten (2) | |

| Repeat for the opposite side. | |

|

|

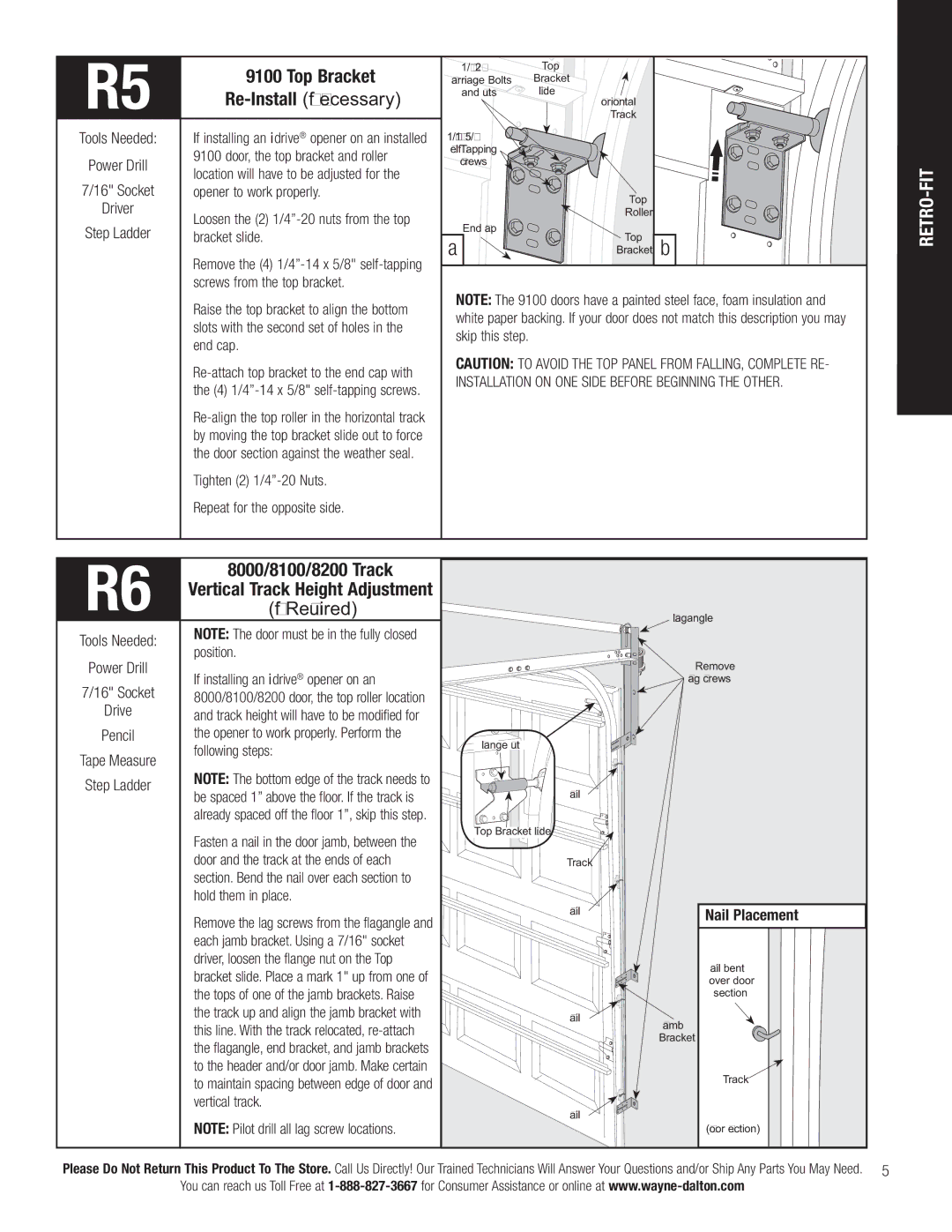

1/4” - 20 | Top |

|

| |

Carriage Bolts | Bracket |

|

| |

and Nuts | Slide |

|

| |

| Horizontal |

|

| |

| Track |

|

| |

1/4”- 14 x 5/8” |

|

|

| |

|

|

| ||

Screws |

|

|

| |

| Top |

| ||

|

| RETRO | ||

| Roller |

| ||

End Cap | Top |

| ||

a | b | |||

Bracket | ||||

|

NOTE: The 9100 doors have a painted steel face, foam insulation and white paper backing. If your door does not match this description you may skip this step.

CAUTION: TO AVOID THE TOP PANEL FROM FALLING, COMPLETE RE- INSTALLATION ON ONE SIDE BEFORE BEGINNING THE OTHER.

R6 | 8000/8100/8200 Track | |

Vertical Track Height Adjustment | ||

(If Required) | ||

Tools Needed: | NOTE: The door must be in the fully closed | |

position. | ||

Power Drill | ||

If installing an idrive® opener on an | ||

7/16" Socket | ||

8000/8100/8200 door, the top roller location | ||

Drive | and track height will have to be modified for | |

Pencil | the opener to work properly. Perform the | |

Tape Measure | following steps: | |

| ||

Step Ladder | NOTE: The bottom edge of the track needs to | |

be spaced 1” above the floor. If the track is | ||

| ||

| already spaced off the floor 1”, skip this step. | |

| Fasten a nail in the door jamb, between the |

Flagangle

Remove |

Lag Screws |

Flange Nut

Nail ![]()

Top Bracket Slide

door and the track at the ends of each |

section. Bend the nail over each section to |

hold them in place. |

Remove the lag screws from the flagangle and |

each jamb bracket. Using a 7/16" socket |

driver, loosen the flange nut on the Top |

bracket slide. Place a mark 1" up from one of |

the tops of one of the jamb brackets. Raise |

the track up and align the jamb bracket with |

this line. With the track relocated, |

the flagangle, end bracket, and jamb brackets |

to the header and/or door jamb. Make certain |

to maintain spacing between edge of door and |

vertical track. |

NOTE: Pilot drill all lag screw locations. |

Track

Nail ![]()

Nail ![]()

Jamb

Bracket

Nail ![]()

Nail Placement

Nail bent over door section

Track

(Door Section)

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need. 5 You can reach us Toll Free at