TorqueMaster®

12 | Setting Spring Tension | |

| ||

|

| |

Tools Needed: | See chart below for proper spring tension setting. | |

| ||

Power Drill | Beginning with the right hand side, ensure the counterbalance | |

cable is in the first groove of the cable drum. NOTE: Apply | ||

| ||

7/16" Socket | light pressure to the canoe clip on counter while winding | |

Driver | springs. | |

| ||

7/16" Wrench | Using a power drill (high torque/gear reduced to 1300 RPM | |

preferred) with a 7/16" socket driver, carefully rotate right | ||

| ||

Step Ladder | hand winding bolt clockwise, until counter shows | |

This will keep the counterbalance cable taut while adjusting | ||

| ||

| the left hand side counterbalance cable. | |

| Adjust left hand counterbalance cable tension (Refer to step | |

| 10). | |

| NOTE: Single spring applications require no spring winding | |

| on left hand side, but need cable tension adjusted. | |

| IMPORTANT! Ensure counterbalance cable tension is equal | |

| for both sides prior to fully winding spring(s) to appropriate | |

| number of turns. If cable tension is unequal, refer to Step 10. | |

| See the Spring Turn chart. | |

| For SINGLE SPRING applications, return to the right hand | |

| side and carefully rotate the winding bolt head clockwise until | |

| the counter shows the correct number of turns for your door | |

| or the number record during the | |

| page II. | |

| For DOUBLE SPRING applications, remain on the left hand | |

| side and carefully rotate the winding bolt head clockwise until | |

| the counter shows the correct number of turns for your door | |

| or the number record during the | |

| page II. Then return to the right hand side and wind the right | |

| hand spring to the required number of turns for your door or | |

| the number recorded during the | |

| page II. | |

| IMPORTANT! DO NOT OVERWIND. | |

| After spring is wound, hold the lock nut (in back of end | |

| bracket) stationary with a 7/16" wrench while rotating the | |

| winding bolt clockwise until snug. Tightening of the lock nut | |

| prevents spring from unwinding. Repeat for opposite side on | |

| double spring Torquemaster® systems. | |

| IMPORTANT! CAUTIOUSLY REMOVE VICE CLAMPS FROM | |

| VERTICAL TRACKS. ADJUSTMENTS TO THE RECOMMENDED | |

| NUMBER OF TURNS MAY BE REQUIRED. IF DOOR RAISES | |

| OFF THE FLOOR UNDER SPRING TENSION ALONE, THEN | |

| REDUCE SPRING TENSION UNTIL DOOR RESTS ON THE | |

| FLOOR. IF THE DOOR IS HARD TO RAISE OR DRIFTS DOWN | |

| ON ITS OWN, THEN ADD SPRING TENSION. AN | |

| UNBALANCED DOOR CAN CAUSE IDRIVE® OPERATION | |

| PROBLEMS. | |

| IMPORTANT! IF YOU ARE INSTALLING THE IDRIVE® | |

| OPENER ON A NEW GARAGE DOOR, REAR SUPPORTS WILL | |

| NEED TO BE FABRICATED/ INSTALLED TO SUPPORT THE | |

| HORIZONTAL TRACKS. REAR SUPPORTS ARE | |

| CONSTRUCTED USING PERFORATED ANGLES, HEX HEAD | |

| BOLTS/NUTS AND THEN THE MUST BE SECURELY | |

| ATTACHED TO SOUND FRAMING MEMBERS WITH LAG | |

| SCREWS. FOR DETAILED INFORMATION ON | |

| CONSTRUCTING/ SUPPORTING THE REAR SUPPORTS, | |

| REFER TO YOUR DOORS INSTALLATION INSTRUCTIONS | |

| AND OWNER’S MANUAL. | |

|

|

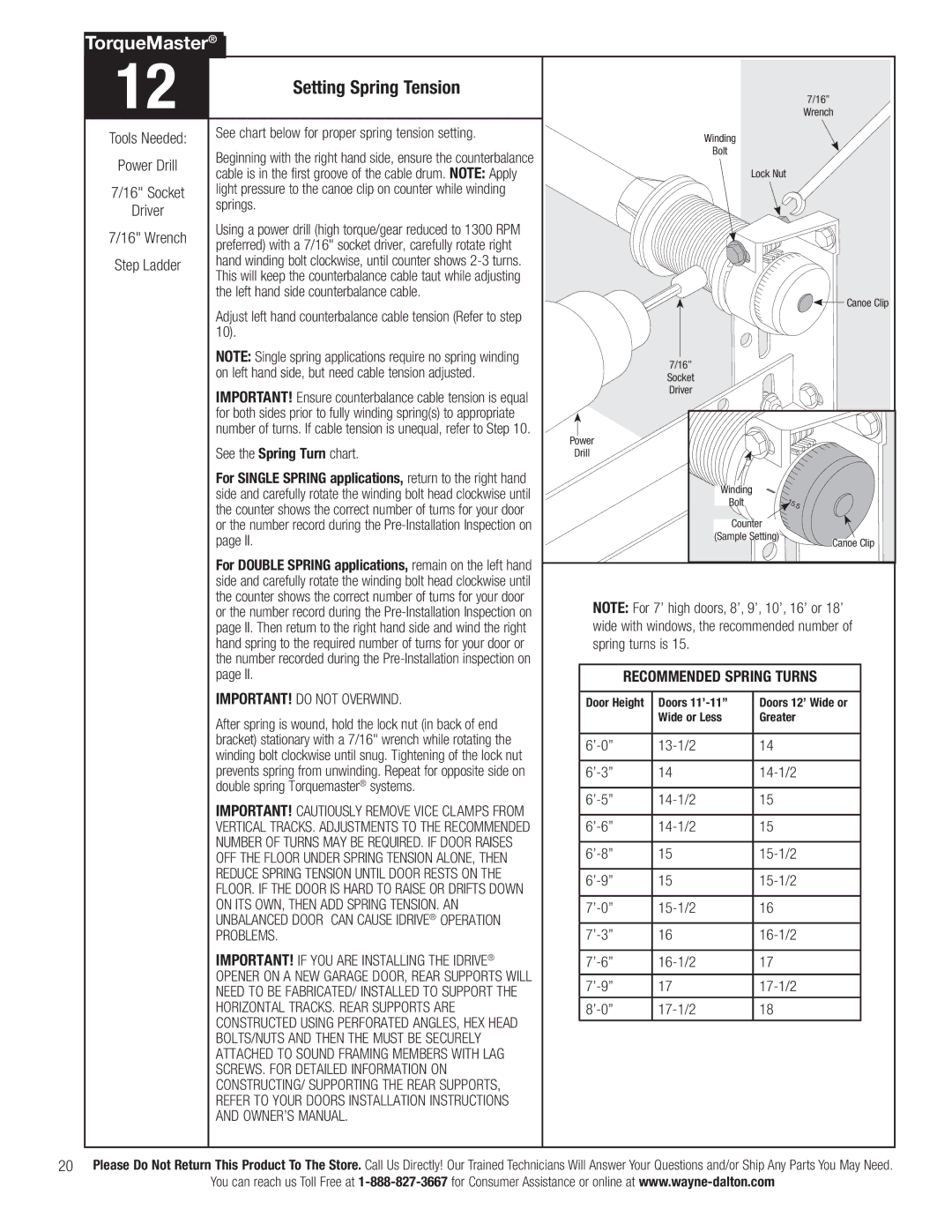

7/16” Wrench

Winding

Bolt

Lock Nut

![]()

![]() Canoe Clip

Canoe Clip

7/16” Socket Driver

Power

Drill

Winding

Bolt

Counter

(Sample Setting)

Canoe Clip

NOTE: For 7’ high doors, 8’, 9’, 10’, 16’ or 18’ wide with windows, the recommended number of spring turns is 15.

RECOMMENDED SPRING TURNS

Door Height | Doors | Doors 12’ Wide or |

| Wide or Less | Greater |

|

|

|

|

| 14 |

|

|

|

| 14 |

|

|

|

|

| 15 | |

|

|

|

| 15 | |

|

|

|

| 15 |

|

|

|

|

| 15 | |

|

|

|

16 | ||

|

|

|

16 |

| |

|

|

|

17 | ||

|

|

|

17 |

| |

|

|

|

18 | ||

|

|

|

20Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at