be no lower than the value determined by referring to the formula below:

| 15 x % LOAD | ) | |

Min. ECWT = | 100 | ||

where: |

|

|

|

ECWT | = entering condensing water temperature | ||

LCHWT | = leaving chilled water temperature |

| |

C RANGE = condensing water temperature range |

| ||

At

CHECKING OPERATION

During operation, the following conditions should be periodically checked:

1.On starting, the prerotation vanes should remain closed until the compressor motor is up to speed on the run winding; then the vane motor should cause the vanes to modulate with load requirements.

FORM

2.Be sure the oil pump is operating while unit is run- ning.

3.Check Oil Pressure display. A gradual decrease in bearing oil pressure of 5 to 10 psi (with constant suction and discharge pressures) may be an indi- cation of a dirty filter. The filter should be replaced when pressure loss is 30% or more of the original pressure. The actual bearing oil pressure will vary with compressor suction and discharge pressures. When a new system is first operated under normal full load conditions, the bearing oil pressure should be recorded as a reference point with which to com- pare subsequent readings.

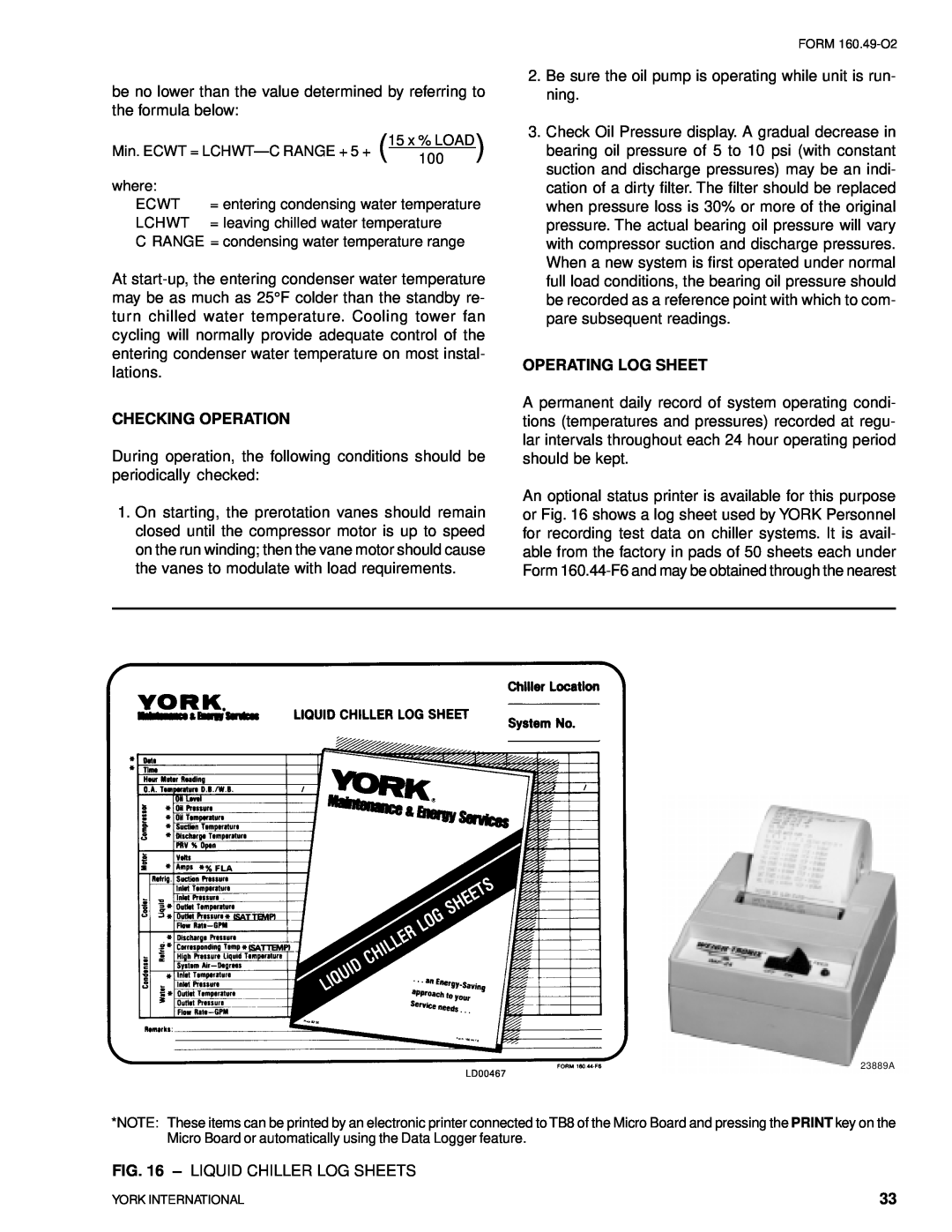

OPERATING LOG SHEET

A permanent daily record of system operating condi- tions (temperatures and pressures) recorded at regu- lar intervals throughout each 24 hour operating period should be kept.

An optional status printer is available for this purpose or Fig. 16 shows a log sheet used by YORK Personnel for recording test data on chiller systems. It is avail- able from the factory in pads of 50 sheets each under Form

23889A

LD00467

*NOTE: These items can be printed by an electronic printer connected to TB8 of the Micro Board and pressing the PRINT key on the Micro Board or automatically using the Data Logger feature.

FIG. 16 – LIQUID CHILLER LOG SHEETS

YORK INTERNATIONAL | 33 |