GENERAL

The YORK Model YK Millennium Centrifugal Liquid Chiller is completely

The initial charge of refrigerant and oil is supplied for each unit. Oil is shipped in containers with the chiller. Refrigerant is shipped to the jobsite in cylinders at the time of installation.

The services of a YORK

COMPRESSOR

The compressor is a

The rotor assembly consists of a

The inserted type journal and thrust bearings are fabri- cated of aluminum alloy. Single helical gears with crowned teeth are designed so that more than one tooth is in contact at all times. Gears are integrally as- sembled in the compressor rotor support and are film lubricated. Each gear is individually mounted in its own journal and thrust bearings.

The

CAPACITY CONTROL

Prerotation vanes (PRV) modulate chiller capacity from 100% to as low as 15% of design for normal air condi- tioning applications. Operation is by an external, elec- tric PRV actuator which automatically controls the vane position to maintain a constant leaving chilled liquid temperature.

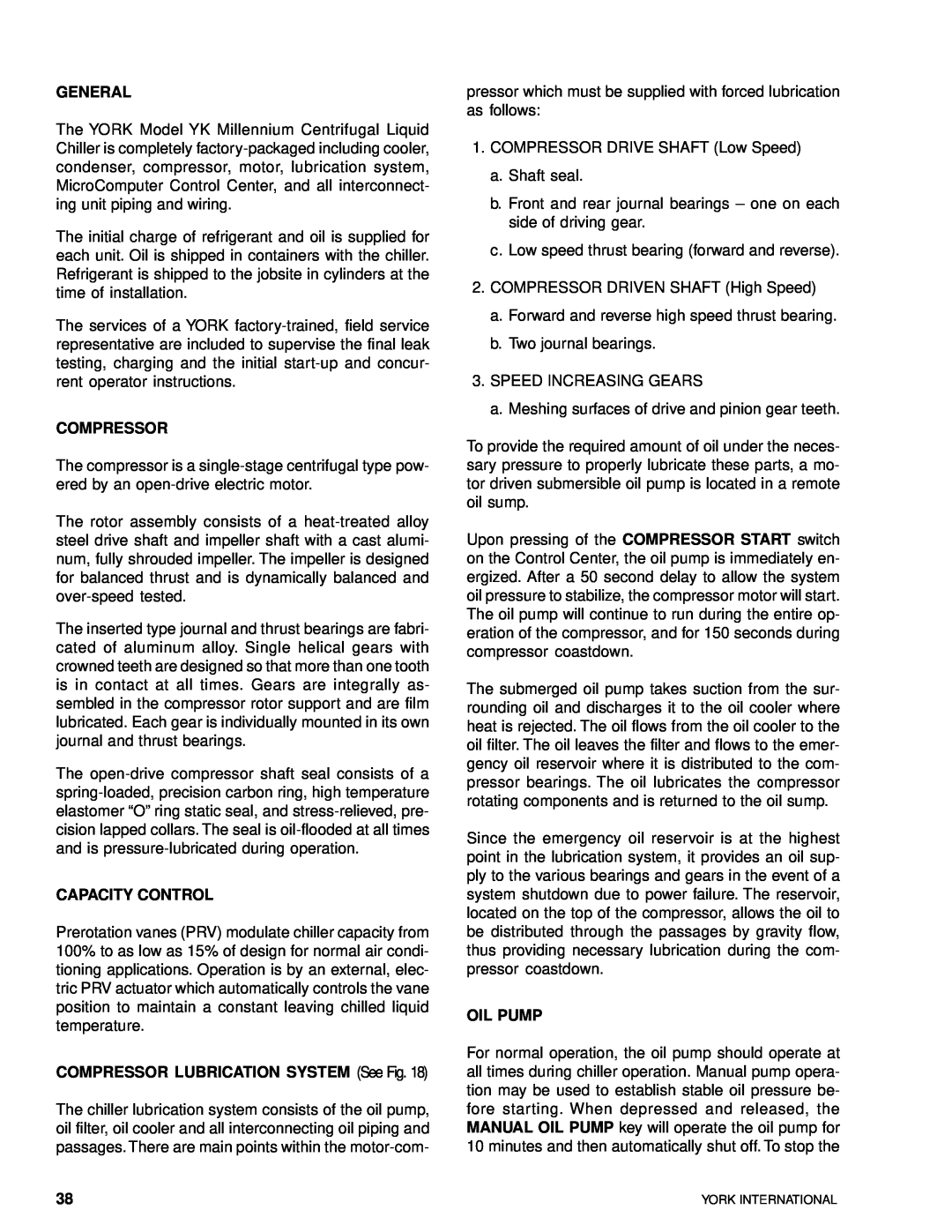

COMPRESSOR LUBRICATION SYSTEM (See Fig. 18)

The chiller lubrication system consists of the oil pump, oil filter, oil cooler and all interconnecting oil piping and passages. There are main points within the

pressor which must be supplied with forced lubrication as follows:

1.COMPRESSOR DRIVE SHAFT (Low Speed)

a.Shaft seal.

b.Front and rear journal bearings – one on each side of driving gear.

c.Low speed thrust bearing (forward and reverse).

2.COMPRESSOR DRIVEN SHAFT (High Speed)

a.Forward and reverse high speed thrust bearing.

b.Two journal bearings.

3.SPEED INCREASING GEARS

a.Meshing surfaces of drive and pinion gear teeth.

To provide the required amount of oil under the neces- sary pressure to properly lubricate these parts, a mo- tor driven submersible oil pump is located in a remote oil sump.

Upon pressing of the COMPRESSOR START switch on the Control Center, the oil pump is immediately en- ergized. After a 50 second delay to allow the system oil pressure to stabilize, the compressor motor will start. The oil pump will continue to run during the entire op- eration of the compressor, and for 150 seconds during compressor coastdown.

The submerged oil pump takes suction from the sur- rounding oil and discharges it to the oil cooler where heat is rejected. The oil flows from the oil cooler to the oil filter. The oil leaves the filter and flows to the emer- gency oil reservoir where it is distributed to the com- pressor bearings. The oil lubricates the compressor rotating components and is returned to the oil sump.

Since the emergency oil reservoir is at the highest point in the lubrication system, it provides an oil sup- ply to the various bearings and gears in the event of a system shutdown due to power failure. The reservoir, located on the top of the compressor, allows the oil to be distributed through the passages by gravity flow, thus providing necessary lubrication during the com- pressor coastdown.

OIL PUMP

For normal operation, the oil pump should operate at all times during chiller operation. Manual pump opera- tion may be used to establish stable oil pressure be- fore starting. When depressed and released, the MANUAL OIL PUMP key will operate the oil pump for 10 minutes and then automatically shut off. To stop the

38 | YORK INTERNATIONAL |