REFRIGERANT CHARGING

To avoid the possibility if freezing liquid within the cooler tubes when charging an evacuated sys-

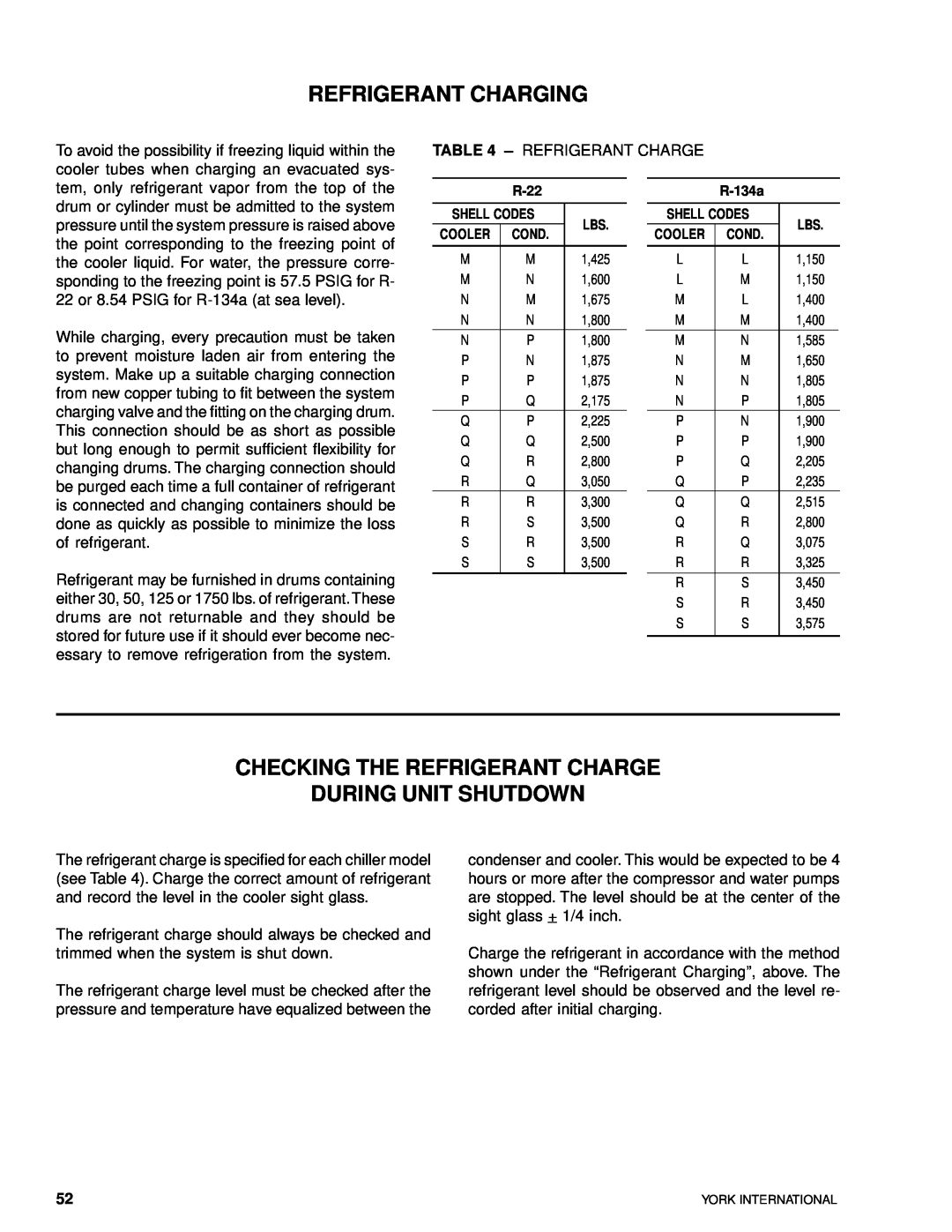

TABLE 4 – REFRIGERANT CHARGE

tem, only refrigerant vapor from the top of the drum or cylinder must be admitted to the system pressure until the system pressure is raised above the point corresponding to the freezing point of the cooler liquid. For water, the pressure corre- sponding to the freezing point is 57.5 PSIG for R- 22 or 8.54 PSIG for

While charging, every precaution must be taken to prevent moisture laden air from entering the system. Make up a suitable charging connection from new copper tubing to fit between the system charging valve and the fitting on the charging drum. This connection should be as short as possible but long enough to permit sufficient flexibility for changing drums. The charging connection should be purged each time a full container of refrigerant is connected and changing containers should be done as quickly as possible to minimize the loss of refrigerant.

Refrigerant may be furnished in drums containing either 30, 50, 125 or 1750 lbs. of refrigerant.These drums are not returnable and they should be stored for future use if it should ever become nec- essary to remove refrigeration from the system.

SHELL CODES |

| LBS. | |

COOLER | COND. |

| |

|

| ||

|

|

|

|

M | M | 1,425 | |

M | N | 1,600 | |

N | M | 1,675 | |

N | N | 1,800 | |

N | P | 1,800 | |

P | N | 1,875 | |

P | P | 1,875 | |

P | Q | 2,175 | |

Q | P | 2,225 | |

Q | Q | 2,500 | |

Q | R | 2,800 | |

R | Q | 3,050 | |

R | R | 3,300 | |

R | S | 3,500 | |

S | R | 3,500 | |

S | S | 3,500 | |

|

|

|

|

| SHELL CODES |

| LBS. | |

| COOLER | COND. |

| |

|

|

| ||

|

|

|

|

|

| L | L | 1,150 | |

| L | M | 1,150 | |

| M | L | 1,400 | |

| M | M | 1,400 | |

|

|

|

| |

| M | N | 1,585 | |

| N | M | 1,650 | |

| N | N | 1,805 | |

| N | P | 1,805 | |

| P | N | 1,900 | |

| P | P | 1,900 | |

| P | Q | 2,205 | |

| Q | P | 2,235 | |

| Q | Q | 2,515 | |

| Q | R | 2,800 | |

| R | Q | 3,075 | |

| R | R | 3,325 | |

|

|

|

| |

| R | S | 3,450 | |

| S | R | 3,450 | |

| S | S | 3,575 | |

|

|

|

|

|

CHECKING THE REFRIGERANT CHARGE

DURING UNIT SHUTDOWN

The refrigerant charge is specified for each chiller model (see Table 4). Charge the correct amount of refrigerant and record the level in the cooler sight glass.

The refrigerant charge should always be checked and trimmed when the system is shut down.

The refrigerant charge level must be checked after the pressure and temperature have equalized between the

condenser and cooler. This would be expected to be 4 hours or more after the compressor and water pumps are stopped. The level should be at the center of the sight glass + 1/4 inch.

Charge the refrigerant in accordance with the method shown under the “Refrigerant Charging”, above. The refrigerant level should be observed and the level re- corded after initial charging.

52 | YORK INTERNATIONAL |