46

YORK INTERNATIONAL

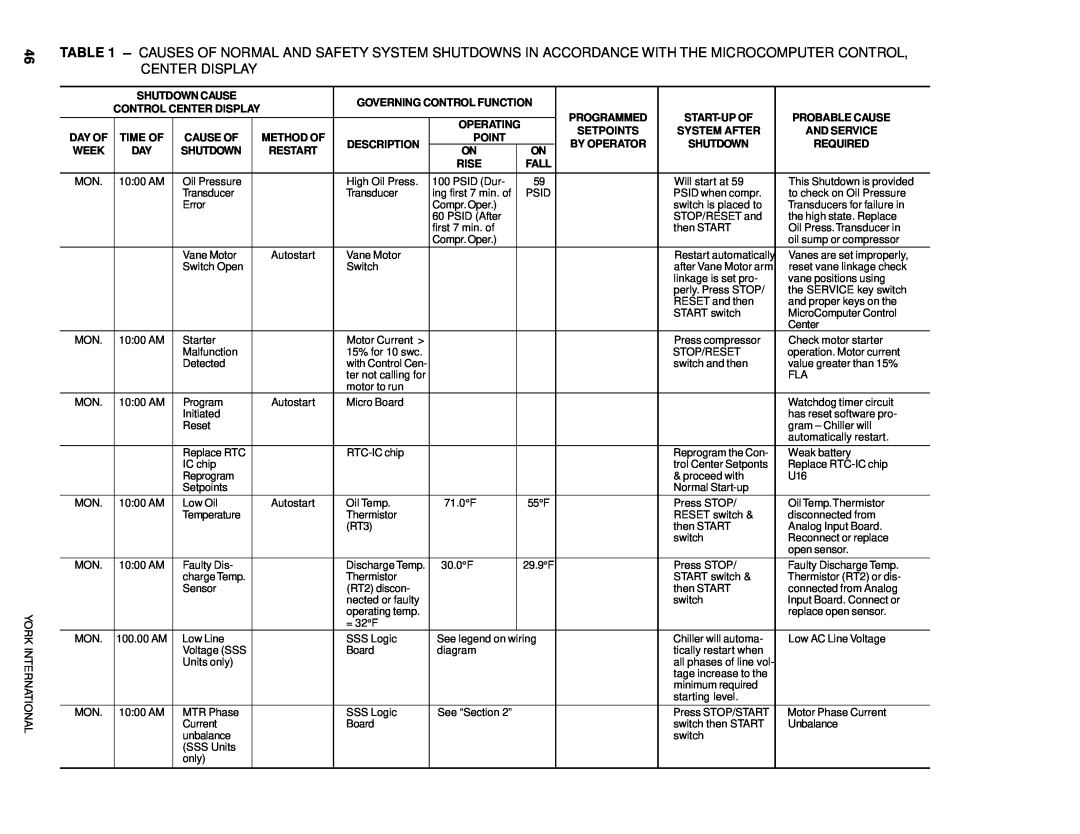

TABLE 1 – CAUSES OF NORMAL AND SAFETY SYSTEM SHUTDOWNS IN ACCORDANCE WITH THE MICROCOMPUTER CONTROL, CENTER DISPLAY

| SHUTDOWN CAUSE |

| GOVERNING CONTROL FUNCTION |

|

|

| |||||

| CONTROL CENTER DISPLAY |

|

|

|

| ||||||

|

|

|

|

|

| PROGRAMMED | PROBABLE CAUSE | ||||

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

| OPERATING |

| ||||

|

|

|

|

|

|

| SETPOINTS | SYSTEM AFTER | AND SERVICE | ||

DAY OF | TIME OF | CAUSE OF |

| METHOD OF |

| POINT |

| ||||

| DESCRIPTION |

| BY OPERATOR | SHUTDOWN | REQUIRED | ||||||

WEEK | DAY | SHUTDOWN |

| RESTART | ON |

| ON | ||||

|

|

|

|

|

| ||||||

|

|

|

|

|

| RISE |

| FALL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MON. | 10:00 AM | Oil Pressure |

|

| High Oil Press. | 100 PSID (Dur- |

| 59 |

| Will start at 59 | This Shutdown is provided |

|

| Transducer |

|

| Transducer | ing first 7 min. of |

| PSID |

| PSID when compr. | to check on Oil Pressure |

|

| Error |

|

|

| Compr. Oper.) |

|

|

| switch is placed to | Transducers for failure in |

|

|

|

|

|

| 60 PSID (After |

|

|

| STOP/RESET and | the high state. Replace |

|

|

|

|

|

| first 7 min. of |

|

|

| then START | Oil Press.Transducer in |

|

|

|

|

|

| Compr. Oper.) |

|

|

|

| oil sump or compressor |

|

| Vane Motor |

| Autostart | Vane Motor |

|

|

|

| Restart automatically | Vanes are set improperly, |

|

| Switch Open |

|

| Switch |

|

|

|

| after Vane Motor arm | reset vane linkage check |

|

|

|

|

|

|

|

|

|

| linkage is set pro- | vane positions using |

|

|

|

|

|

|

|

|

|

| perly. Press STOP/ | the SERVICE key switch |

|

|

|

|

|

|

|

|

|

| RESET and then | and proper keys on the |

|

|

|

|

|

|

|

|

|

| START switch | MicroComputer Control |

|

|

|

|

|

|

|

|

|

|

| Center |

MON. | 10:00 AM | Starter |

|

| Motor Current > |

|

|

|

| Press compressor | Check motor starter |

|

| Malfunction |

|

| 15% for 10 swc. |

|

|

|

| STOP/RESET | operation. Motor current |

|

| Detected |

|

| with Control Cen- |

|

|

|

| switch and then | value greater than 15% |

|

|

|

|

| ter not calling for |

|

|

|

|

| FLA |

|

|

|

|

| motor to run |

|

|

|

|

|

|

MON. | 10:00 AM | Program |

| Autostart | Micro Board |

|

|

|

|

| Watchdog timer circuit |

|

| Initiated |

|

|

|

|

|

|

|

| has reset software pro- |

|

| Reset |

|

|

|

|

|

|

|

| gram – Chiller will |

|

|

|

|

|

|

|

|

|

|

| automatically restart. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Replace RTC |

|

|

|

|

|

| Reprogram the Con- | Weak battery | |

|

| IC chip |

|

|

|

|

|

|

| trol Center Setponts | Replace |

|

| Reprogram |

|

|

|

|

|

|

| & proceed with | U16 |

|

| Setpoints |

|

|

|

|

|

|

| Normal |

|

MON. | 10:00 AM | Low Oil |

| Autostart | Oil Temp. | 71.0°F |

| 55°F |

| Press STOP/ | Oil Temp.Thermistor |

|

| Temperature |

|

| Thermistor |

|

|

|

| RESET switch & | disconnected from |

|

|

|

|

| (RT3) |

|

|

|

| then START | Analog Input Board. |

|

|

|

|

|

|

|

|

|

| switch | Reconnect or replace |

|

|

|

|

|

|

|

|

|

|

| open sensor. |

|

|

|

|

|

|

|

|

|

|

|

|

MON. | 10:00 AM | Faulty Dis- |

|

| Discharge Temp. | 30.0°F |

| 29.9°F |

| Press STOP/ | Faulty Discharge Temp. |

|

| charge Temp. |

|

| Thermistor |

|

|

|

| START switch & | Thermistor (RT2) or dis- |

|

| Sensor |

|

| (RT2) discon- |

|

|

|

| then START | connected from Analog |

|

|

|

|

| nected or faulty |

|

|

|

| switch | Input Board. Connect or |

|

|

|

|

| operating temp. |

|

|

|

|

| replace open sensor. |

|

|

|

|

| = 32°F |

|

|

|

|

|

|

MON. | 100.00 AM | Low Line |

|

| SSS Logic | See legend on wiring |

| Chiller will automa- | Low AC Line Voltage | ||

|

| Voltage (SSS |

|

| Board | diagram |

|

| tically restart when |

| |

|

| Units only) |

|

|

|

|

|

|

| all phases of line vol- |

|

|

|

|

|

|

|

|

|

|

| tage increase to the |

|

|

|

|

|

|

|

|

|

|

| minimum required |

|

|

|

|

|

|

|

|

|

|

| starting level. |

|

|

|

|

|

|

|

|

|

|

|

|

|

MON. | 10:00 AM | MTR Phase |

|

| SSS Logic | See “Section 2” |

|

| Press STOP/START | Motor Phase Current | |

|

| Current |

|

| Board |

|

|

|

| switch then START | Unbalance |

|

| unbalance |

|

|

|

|

|

|

| switch |

|

|

| (SSS Units |

|

|

|

|

|

|

|

|

|

|

| only) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|